Driving the Future: Advanced Chassis and Body Engineering Solutions

Engineering the Core of Performance

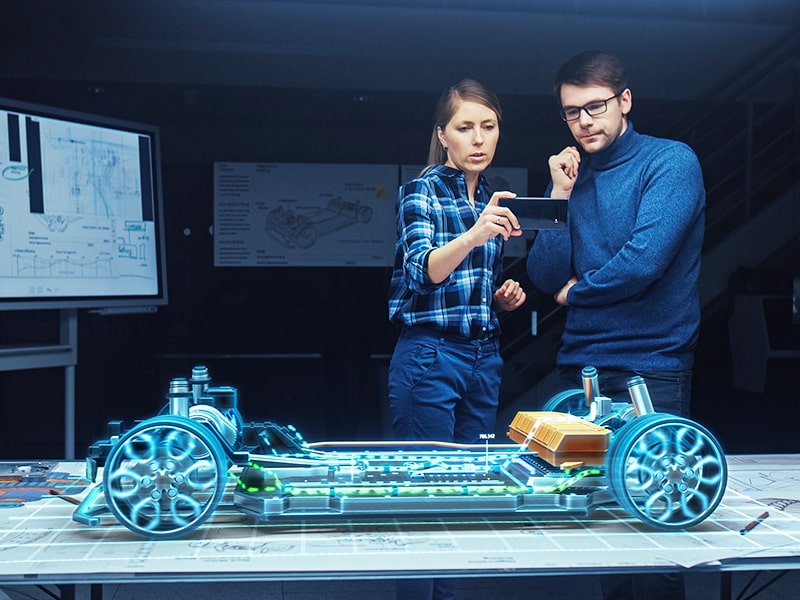

Engineering Excellence in Chassis and Body Structures for Next-Gen Mobility

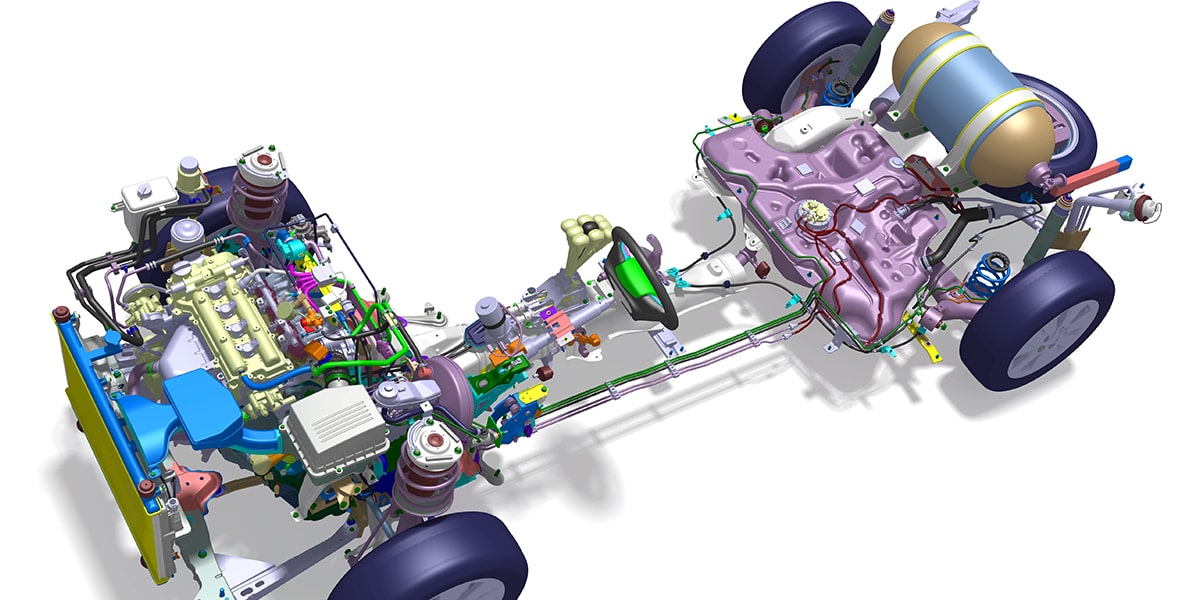

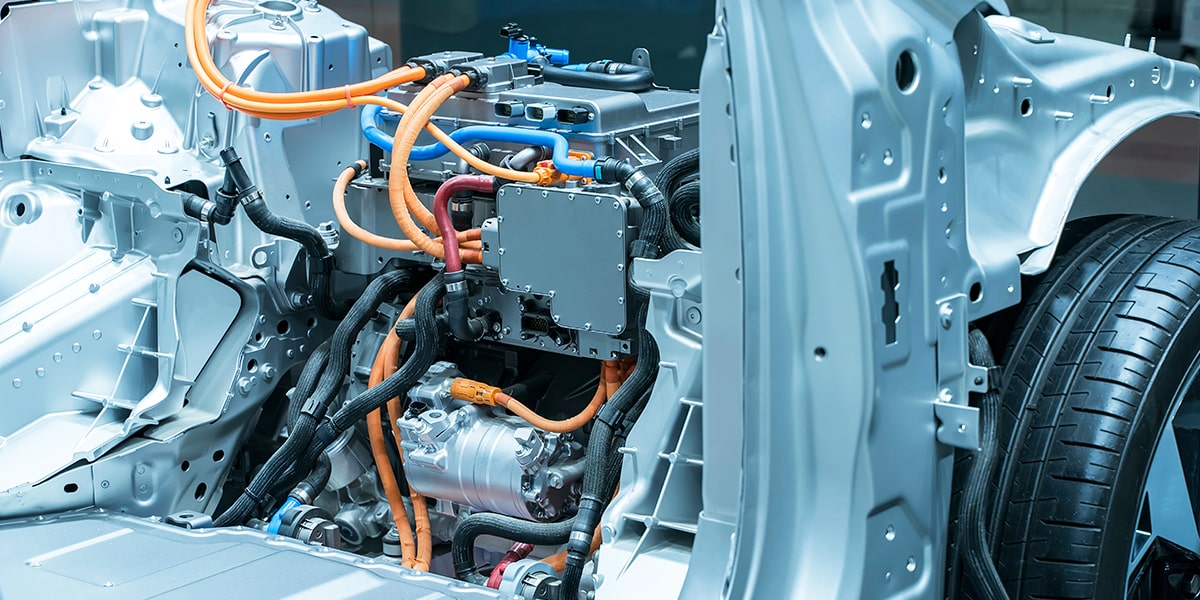

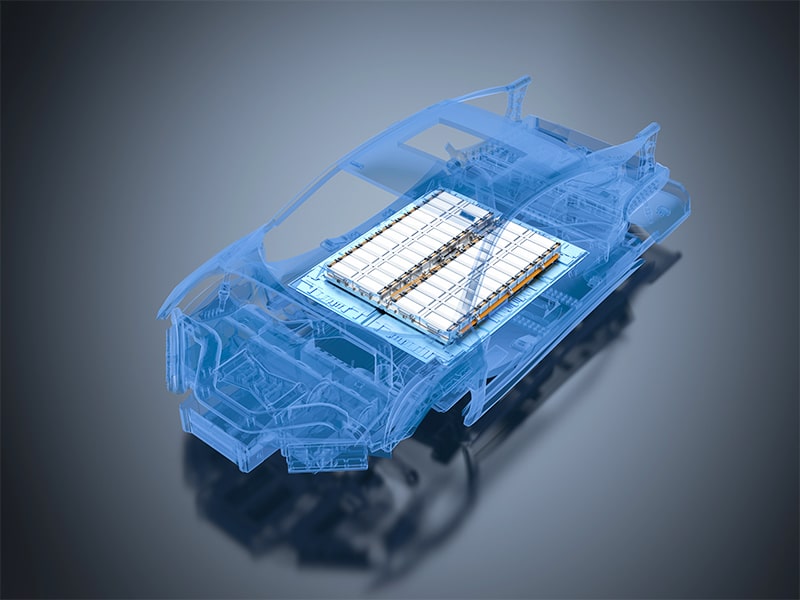

At Detroit Engineered Products (DEP), we specialize in delivering advanced engineering solutions for chassis systems and body structures, empowering the automotive industry with high-performance, lightweight, and safety-focused designs. Our chassis engineering expertise focuses on optimizing vehicle dynamics, structural stiffness, and weight efficiency by integrating advanced materials and cutting-edge design approaches to enhance durability, reduce mass, and elevate ride comfort. From active suspension systems to intelligent chassis control modules, we enable vehicles to meet the highest benchmarks of performance, handling, and occupant safety. In body structure engineering, DEP adopts a holistic approach, prioritizing crash safety, manufacturability, and aesthetic quality, offering solutions designed for structural integrity, cost-effective production, and superior visual refinement. As the shift to electric and hybrid mobility accelerates, we help OEMs adapt chassis and body designs to meet the unique demands of new propulsion technologies, ensuring future-ready, sustainable vehicles. With innovation at the core, DEP remains a trusted partner in engineering the next generation of automotive excellence.

Focus Area

NVH

BIW and trim body modal

Normal modes and stiffness analysis of frame and suspension

Closures sub-system stiffness and modal response

BIW DPDS/Mobility

SPL (sound pressure level) analysis (cavity)

Crash and Safety

Frontal, side, rear, rollover & roof crush simulations

Occupant, component & pedestrian safety

Crash Loadcase set using process automation

USNCAP, IIHS FSOB, Euro NCAP, IIHS Side IDB, lINCAP

Side pole Impact, Roof Crush

FMVSS 207/210/225 analysis for Seat anchorage systems

Durability

Durability load response

Body structure evaluation

Chassis interface analysis

MBD

Suspension hardpoint synthesis using KnC analysis

Tire flop and trim height analysis

Handling evaluation

Static loads/Dynamics Loads for Durability evaluation

Value Engineering

Parametric CAE Models

Multi-disciplinary parametric CAE models

Topology optimization

Component Feature Customization

Design Performance Optimization

Model Building

Conceptual Design Modeling

3D CAD Modeling

Design Validation

Assembly and Manufacturing Integration

Design for Manufacturability (DFM)

Service Capabilities

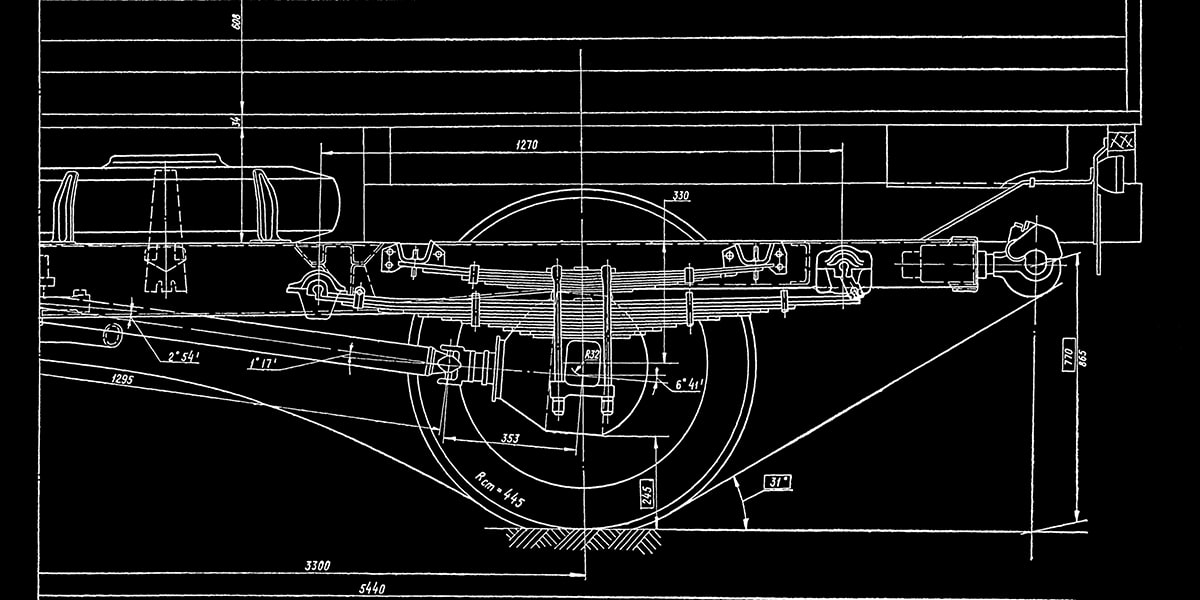

Benchmarking and reverse engineering assess existing vehicle body structures by comparing them with industry standards. This process identifies design improvement areas and optimizes performance while aligning with market demands and technological advancements.