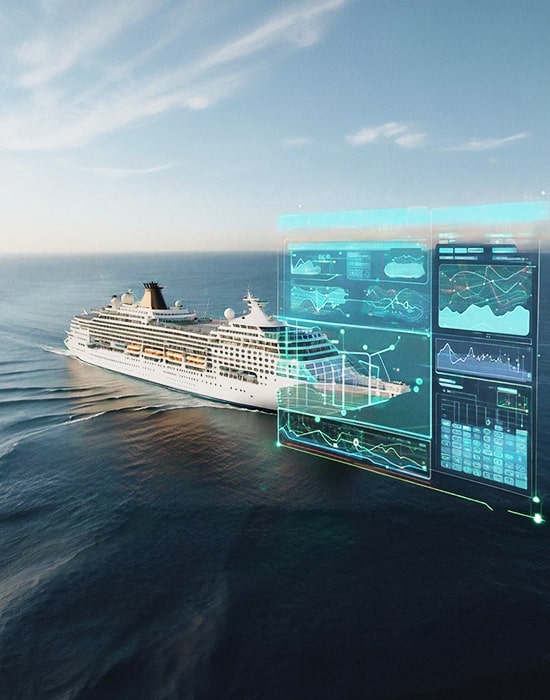

Pioneering Excellence in Marine Engineering: Delivering Superior Performance and Safety

Innovative Design, Enhanced Performance

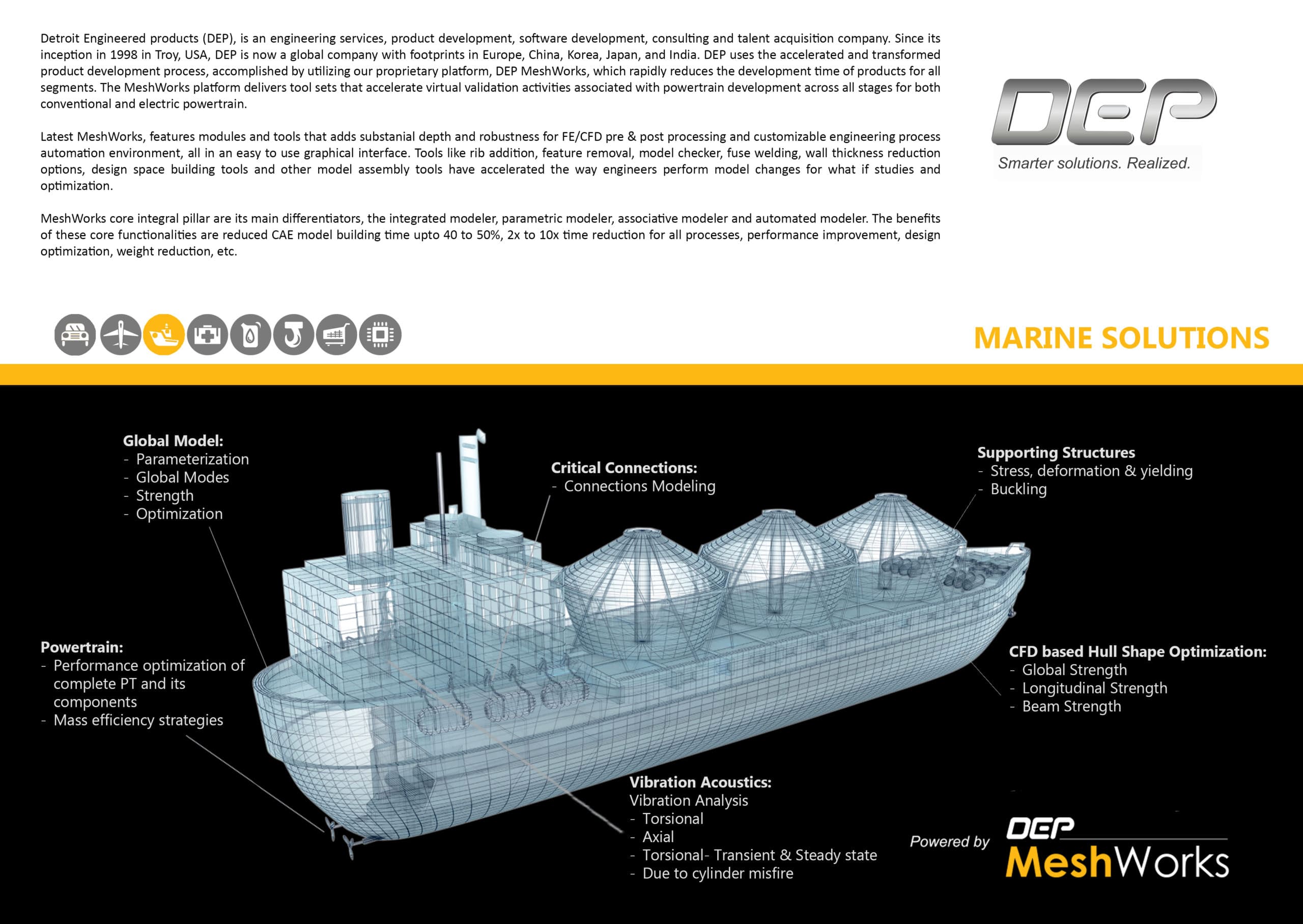

Recent advances in the maritime industry have led to the emergence of new designs with improved seakeeping qualities and significantly increased velocity. Existing ship types, such as bulk carriers, general cargo carriers, tankers, gas carriers, and container ships, have also been modified. While frigate designs have significantly changed, the propulsion systems that are now in use have also changed dramatically. The design and development process must be cost-effective, require minimal manpower, be available when needed, and be overly vulnerable. The safety of the ship, its crew, and the environment in which it sails are all critical. With more than 2 decades of experience from completing many projects and programs, the DEP team can assist in marine product development from concept to production at a faster pace. Ourexpert's team can help from design phase of development to engineering support and plan review, as well as technical services, and deliver quality results for manufacturers in newbuild projects.

Our Services

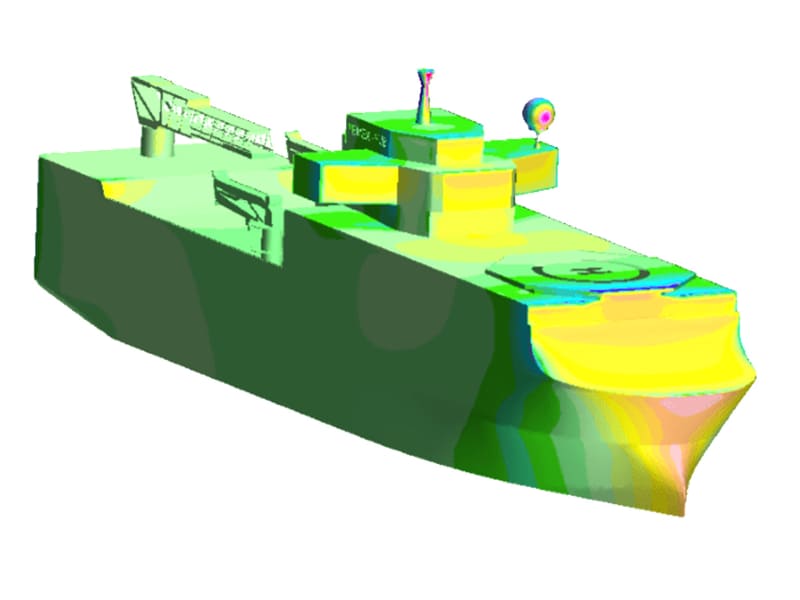

Hull Optimization and Hydrodynamic Analysis

Hull optimization ensures the vessel operates with maximum efficiency, minimizing resistance and improving fuel consumption through advanced hydrodynamic simulations.

DEP Key Capabilities

CFD simulations

Drag reduction

Structural Integrity and Fatigue Analysis

Evaluating the structural integrity of marine vessels is essential to ensure long-term durability under harsh environmental conditions, including wave loads and operational stress.

DEP Key Capabilities

FEA simulations

Fatigue prediction

Marine Propulsion System Design and Simulation

Efficient propulsion system design is critical for reducing fuel consumption and emissions while maximizing vessel speed and manoeuvrability.

DEP Key Capabilities

Propulsion optimization

Multi-physics simulation

Vibration and Noise Control

Reducing vibration and noise is important for enhancing onboard comfort and ensuring compliance with environmental regulations, particularly in passenger vessels.

DEP Key Capabilities

Acoustic analysis

Vibration mitigation

Capabilities

Parameterization

DEP’s parameterization process covers a wide range of areas to optimize designs and improve product performance. This includes shape, structural, and topology optimization, alongside detailed work on welds, adhesives, and composites. Key elements like bulkheads and doublers are also evaluated to enhance the strength and durability of structures. DEP's expertise ensures that every aspect of the design is tailored for optimal efficiency and robustness.

Engineering

DEP offers specialized engineering services for offshore marine engineering, ship structural design, and vibroacoustic analysis. These services are complemented by expertise in transitioning from metal to composite materials and conducting advanced computational fluid dynamics. DEP’s engineering capabilities ensure that marine structures meet high standards of safety, durability, and performance in challenging environments.

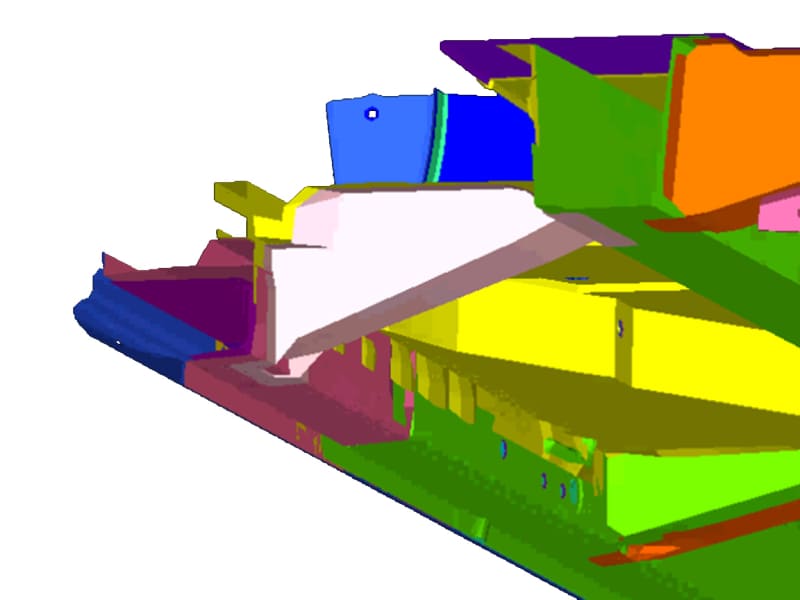

Ship configurations

DEP is well-versed in designing and analyzing various ship configurations, including tankers, bulk carriers, container ships, and ocean liners. Each ship type requires a tailored approach to ensure optimal structural integrity, load management, and fuel efficiency. DEP’s thorough understanding of these vessels enables the development of reliable, high-performance designs.

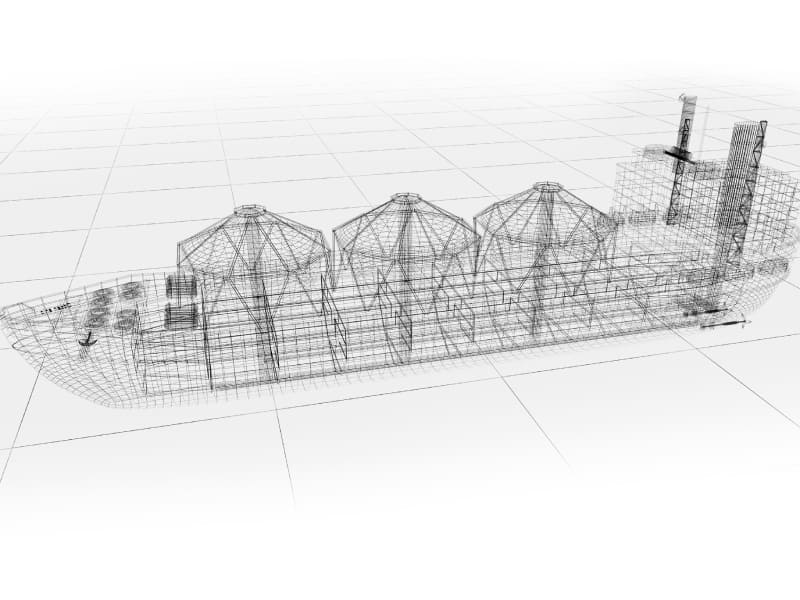

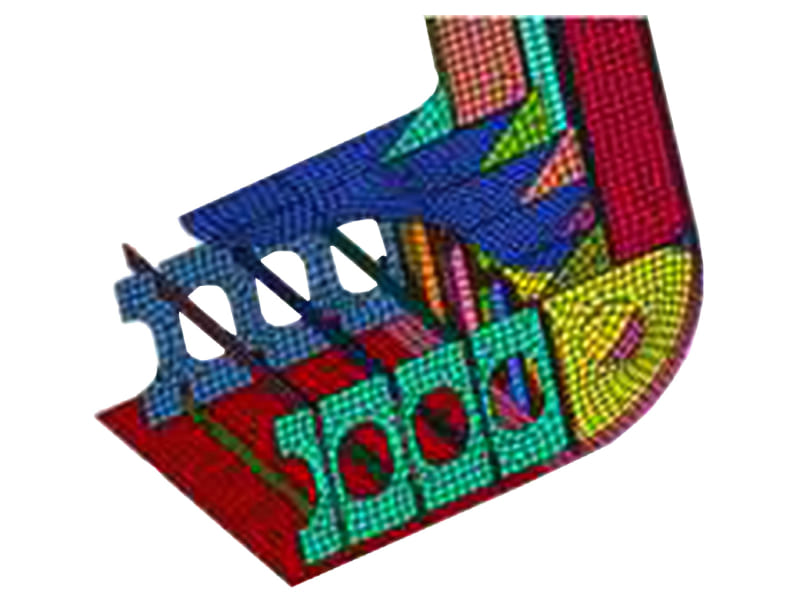

Modelling of Critical Areas

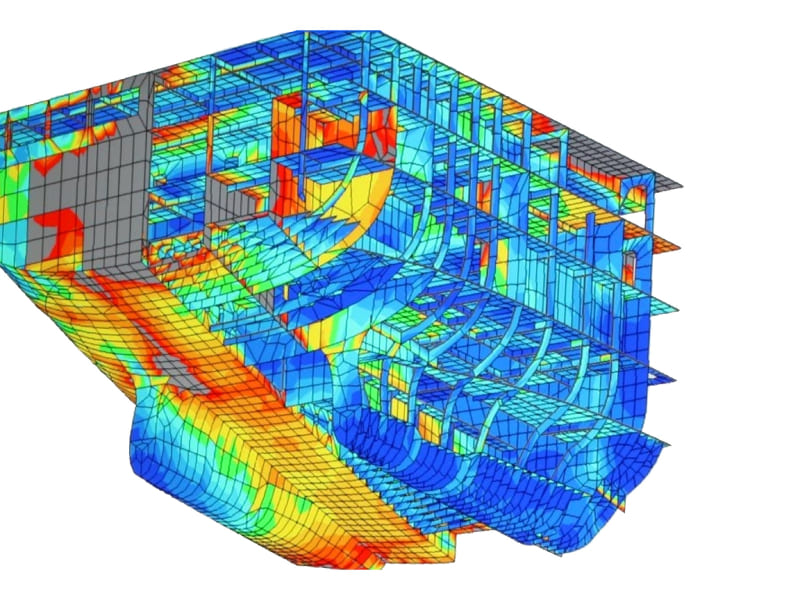

DEP focuses on accurately modelling critical areas such as connections, openings, and bracket toes, along with structural knuckle points. This includes analyzing primary, secondary, and tertiary bending on global finite element (FE) models and assessing stress and deformation for yielding and buckling. Vibroacoustic analysis is also integrated to account for global bending and torsional modes, ensuring a comprehensive understanding of a structure’s behaviour under various conditions.

Vibroacoustic Analysis

DEP's vibroacoustic analysis involves detailed evaluation of global bending and torsional modes, bulkhead stress, and deformation for buckling prevention. The analysis extends to composite ply optimization, acoustic cavity model building, and structure-acoustic coupling. Forced frequency and acoustic response assessments are crucial for minimizing noise and vibration, ensuring quieter, more comfortable operations.

Weight Optimization

DEP’s weight optimization strategies explore alternate configurations and materials, with a focus on lightweight composites. By reducing weight without sacrificing strength or performance, DEP helps improve fuel efficiency and operational costs. The use of advanced materials and design adjustments allows for better structural integrity and reduced environmental impact.

Benefits Of Scalable Marine Solutions