Crash Analysis

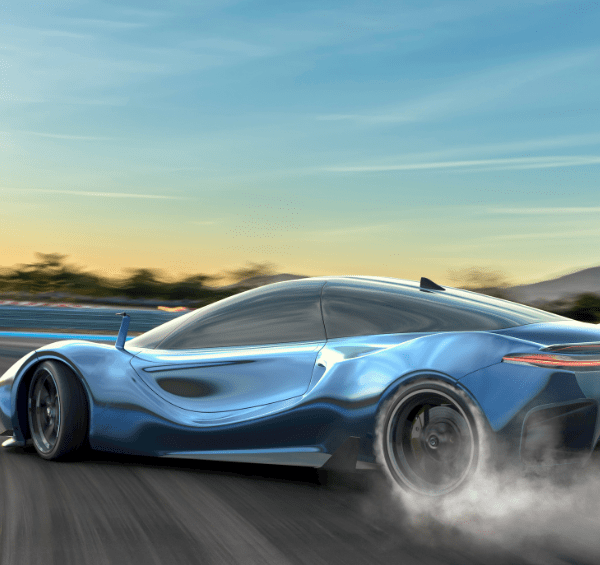

Comprehensive Vehicle Crash Analysis for Safety and Performance Excellence

Advanced solutions forcrashworthydesigns

Crash simulation plays a pivotal role in advancing vehicle safety and durability by virtually analyzing the effects of collisions on structures and occupants. It enables engineers to predict crashworthiness, optimize designs, and enhance occupant protection before physical prototypes are built. By leveraging cutting-edge computational tools, crash simulation accelerates development, reduces costs, and ensures compliance with safety standards.

Crash simulations are utilized across industries such as automotive, aerospace, consumer goods, and medical technology to study and optimize the behavior of structures during collisions. With DEP simulations, we can calculate, analyze, and simulate crash impacts and their effects on durability, including material behavior, structural deformations, joints and fixtures, and other factors in a realistic manner. This ensures that product development meets safety, durability, and industry standards. Key objectives of crash analysis include ensuring driver safety, selecting materials based on strength and durability, minimizing vehicle weight without compromising safety, reducing the cost of physical crash testing, and evaluating frame crashworthiness while identifying design improvements.

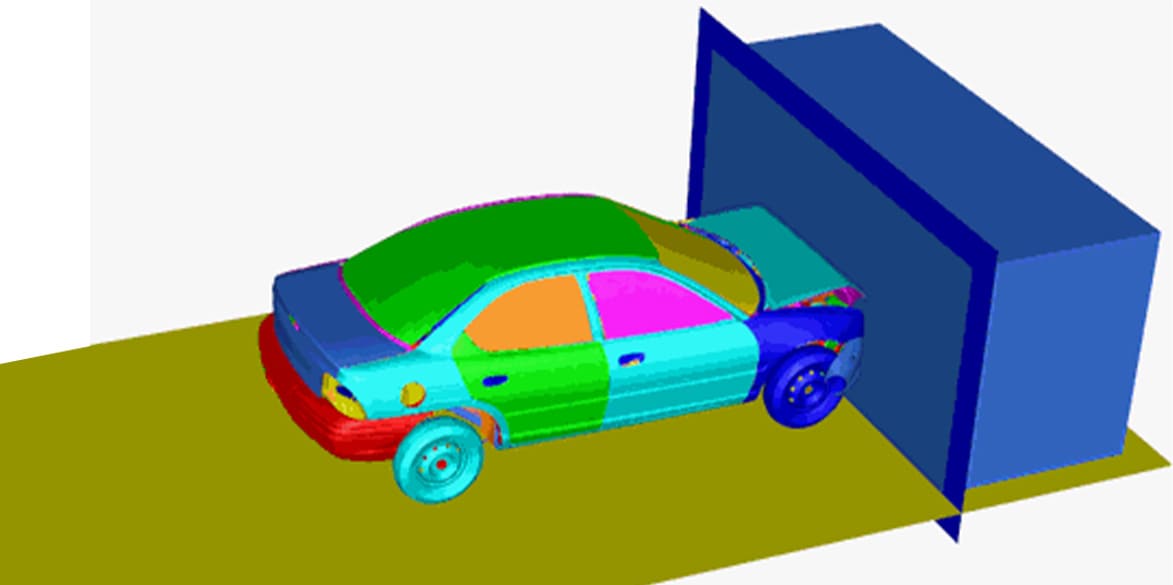

Crash / Structural Simulation Analysis

DEP’s Crash/Structural Simulation optimizes vehicle designs by simulating crash scenarios to ensure strength and compliance with safety standards while reducing weight. This helps enhance vehicle crashworthiness and safety.

Component Safety

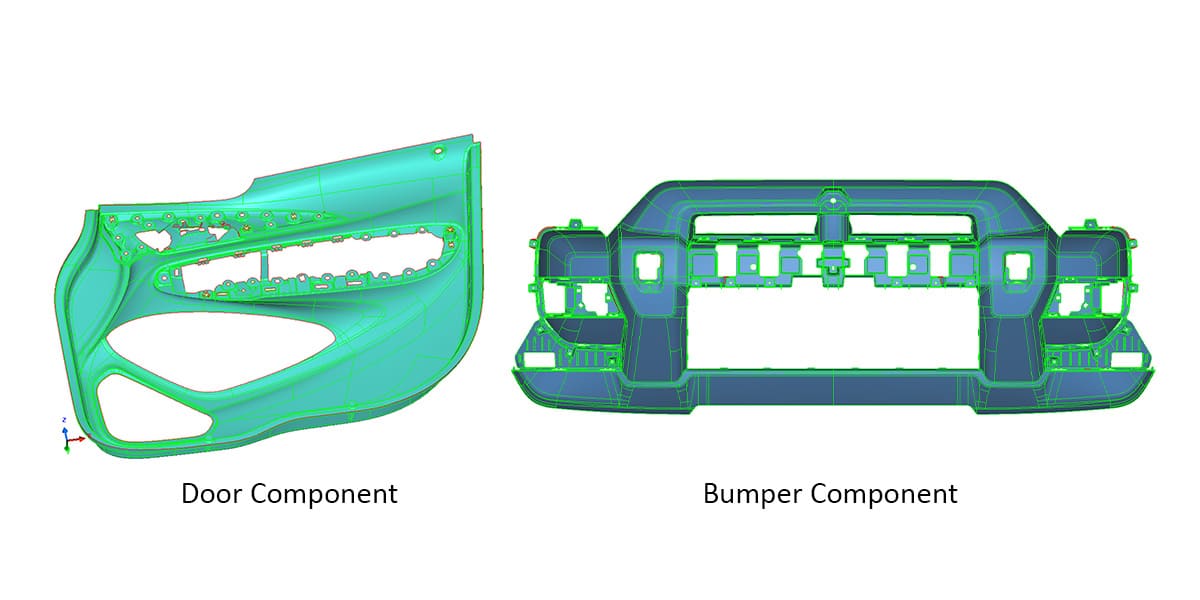

We conduct a detailed Component Safety analysis to evaluate critical vehicle parts under crash conditions, ensuring they meet safety requirements and perform optimally during impacts to protect both the vehicle and its occupants.

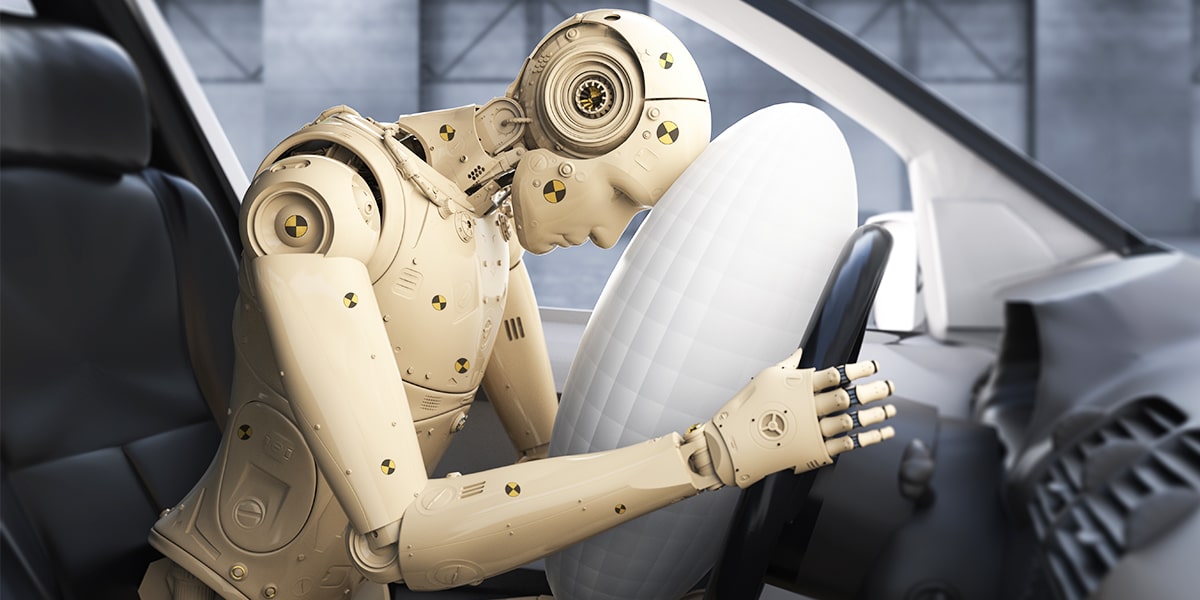

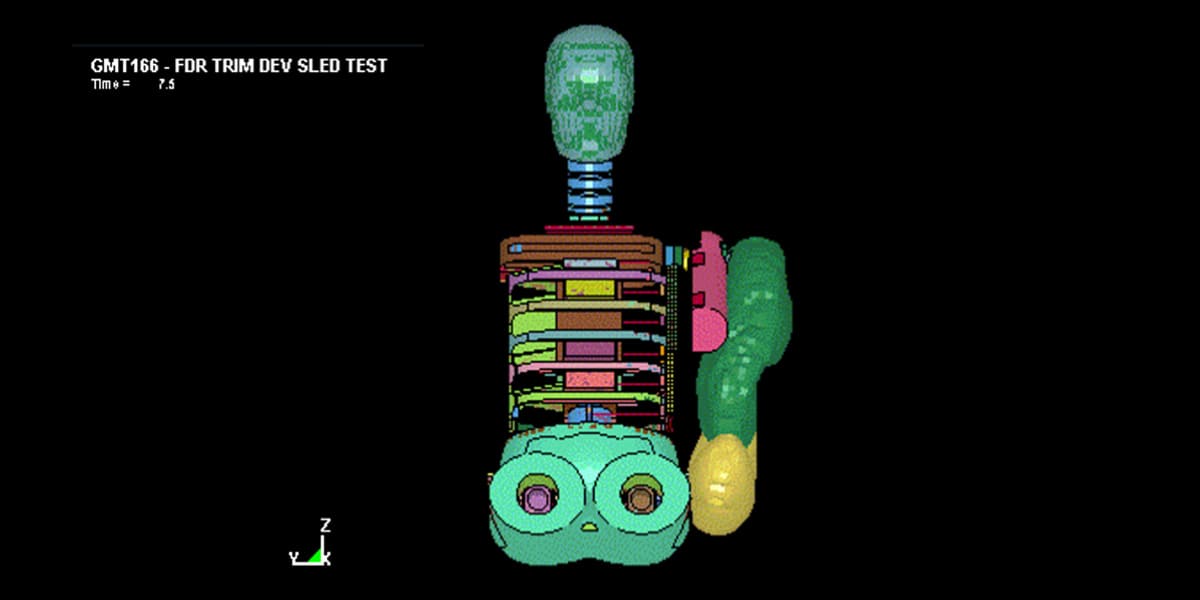

Occupant Safety

DEP’s Occupant Safety simulations focus on protecting passengers in the event of a crash. We assess seatbelts, airbags, and interior designs to ensure maximum safety and compliance with global standards.

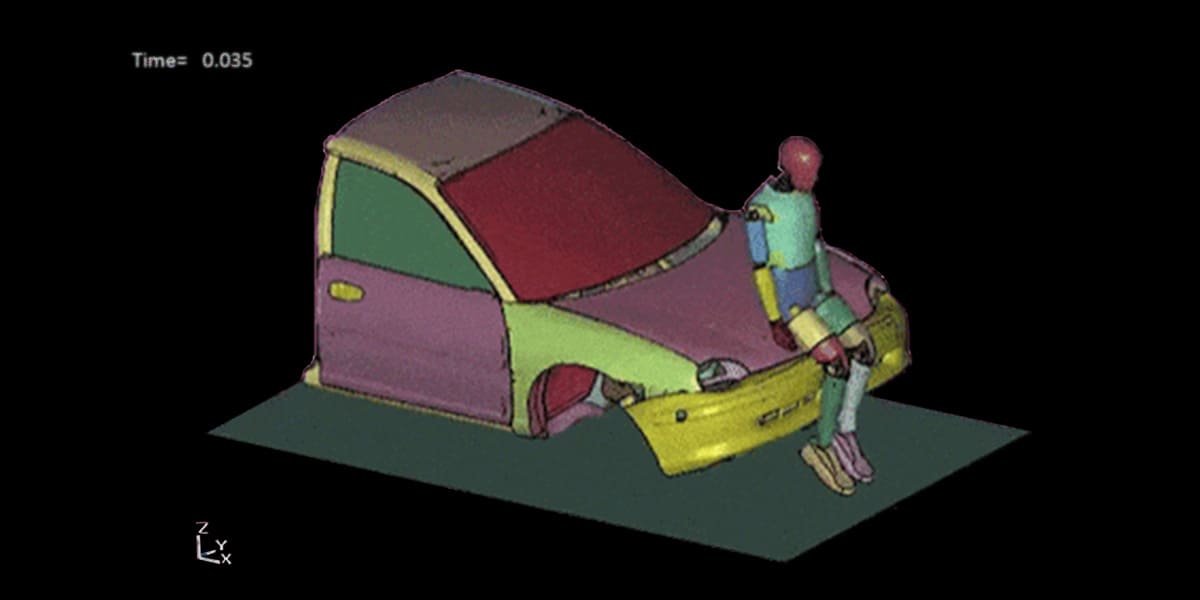

Pedestrian Safety

Our Pedestrian Safety analysis aims to minimize injuries in collisions with vulnerable road users. We test components like bumpers and hoods to develop designs that reduce harm in pedestrian accidents.

Strength and Fatigue Analysis

We perform Strength and Fatigue Analysis to assess vehicle component durability under repeated stress. This ensures parts withstand long-term use without failure, improving reliability and reducing maintenance costs.

Component Durability

DEP’s Component Durability testing simulates real-world conditions to evaluate the longevity of vehicle parts. We focus on ensuring components remain reliable and resilient throughout their lifecycle, minimizing the risk of failure.

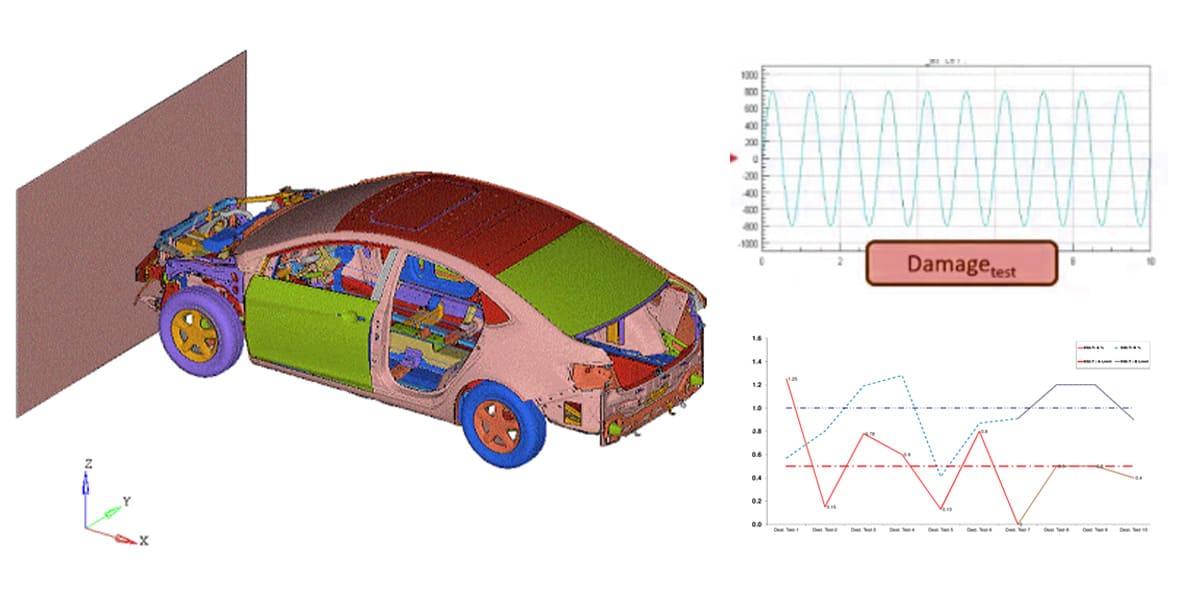

Crash/Structural Simulation Analysis

DEP have an excellent track record of CAE vs. test correlation

Crash/Structural Simulation Analysis Capabilities

Physics-based simulation of impact, crash, and structural failure events

System, assembly, component, and part-level structural assessments

Compliance evaluation against industry standards and safety regulations

Multi-directional impact, drop, crush, and load-case simulations

Progressive damage, material nonlinearity, and failure prediction

Human safety, injury risk, and protective system performance analysis

Energy absorption and crashworthiness optimization

Safety assessment of critical systems and energy-storing components

Parametric studies and design trade-off evaluations

Engineering reports with clear design recommendations

Components Safety

Safety assessment of mechanical, electrical, and electro-mechanical components

Structural integrity and durability evaluation under operating and extreme conditions

Failure mode identification and risk assessment at component level

Material behavior, degradation, and damage tolerance analysis

Impact, drop, crush, and overload safety simulations

Thermal, vibration, and fatigue-driven safety evaluations

Compliance assessment against applicable industry standards and regulations

Design optimization for safety, reliability, and robustness

Validation support through simulation correlation and test planning

Engineering documentation with actionable safety recommendations

Occupant Safety

Human safety and injury risk assessment under impact and operational load cases

Digital human modeling for posture, motion, and interaction analysis

Evaluation of restraint, protection, and safety systems performance

Biomechanical response and injury criteria assessment

Human–system interaction analysis during normal and extreme events

Multi-physics simulation of occupant response to impact, vibration, and acceleration

Parametric studies to optimize safety system design and placement

Compliance assessment with applicable safety standards and guidelines

Correlation of simulation results with physical testing data

Engineering reports with clear safety-driven design recommendations

Pedestrian Safety

External human safety assessment for interactions between products, systems, and people

Impact and contact simulation involving vulnerable road users and bystanders

Injury risk evaluation using biomechanical and human body models

Assessment of surface compliance, energy absorption, and contact forces

Optimization of exterior designs to minimize injury severity

Multi-physics analysis of impact, kinematics, and structural response

Evaluation of active and passive safety features for external human protection

Parametric studies to support safety-driven design decisions

Compliance assessment with applicable safety standards and guidelines

Engineering reports with actionable safety improvement recommendations

Strength and Fatigue Analysis

Static and dynamic strength assessment of components, assemblies, and systems

Stress, strain, and deformation analysis under operational and extreme load cases

Fatigue life prediction under cyclic, random, and variable amplitude loading

Durability assessment considering material nonlinearity and damage accumulation

Evaluation of joints, welds, fasteners, and interfaces for structural reliability

Vibration- and load-induced fatigue analysis

Material characterization and failure criteria implementation

Design optimization for strength, weight, and durability targets

Correlation of simulation results with physical testing and field data

Engineering documentation with clear design and durability recommendations

Component Durability

Durability assessment of components under real-world operating and environmental conditions

Life prediction considering cyclic loads, vibration, thermal effects, and aging

Identification of wear, damage accumulation, and degradation mechanisms

Evaluation of joints, interfaces, and fastening systems for long-term reliability

Material behavior assessment, including fatigue, creep, and corrosion effects

Load spectrum development and duty-cycle-based durability analysis

Design optimization to improve component life and robustness

Correlation of simulation results with physical testing and field data

Support for validation planning and durability test definition

Engineering reports with actionable durability and reliability recommendations

DEP Advantages

We provide exceptional CAE Services and our commitment to provide industry leading Crash and durability Analysis to the global clientele has continued to strengthen our reputation, making us the chosen partner for engineering service in the market. We promise you the advantage of:

Quality Service

Advanced Technology

Custom Tailored Solutions

Expert Support

Competitive Rate

Timely Delivery