Comprehensive Design & Development Solutions

Custom Hardware Design and Development

Advanced Prototyping and Testing

System Integration and Validation

Performance Optimization and Analysis

Value Engineering and Cost Reduction

Future-ready Product Engineering Services and Solutions

The landscape of technology is rapidly evolving, with emerging technologies and one-size-fits-all methodologies adapting to meet growing customer demands. If you aim to bring new technology to market swiftly, DEP is your ideal partner.

DEP has invested decades of research into developing cutting-edge hardware engineering solutions. We provide specialized services such as domain-specific hardware engineering and design, comprehensive product testing, and value-added engineering services.We are committed to continuous innovation, ensuring our hardware solutions remain at the forefront of engineering excellence.

DEP's End-to-End Product Development Solutions

From Concept to Completion: Excellence in Hardware Engineering

At Detroit Engineered Products (DEP), we pride ourselves on delivering comprehensive hardware solutions that span the entire engineering lifecycle. Our expertise and advanced technologies ensure that every phase of your hardware development is executed with precision, reliability, and innovation. Here's how we transform concepts into high-performance hardware:

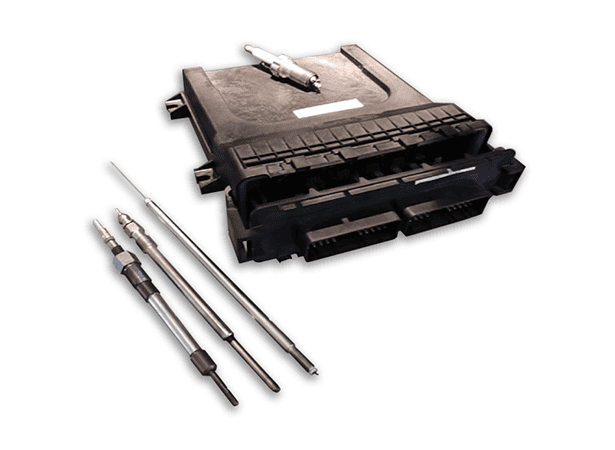

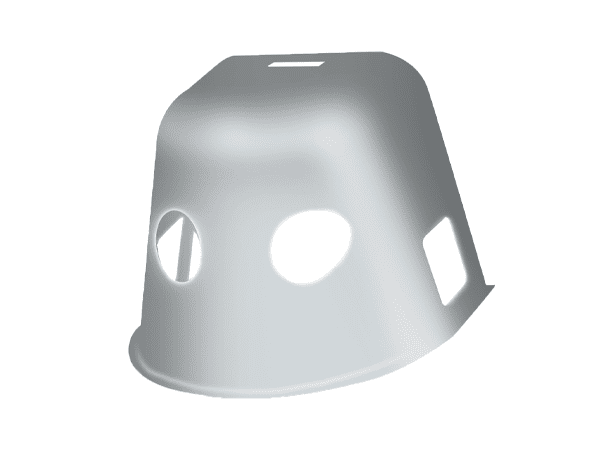

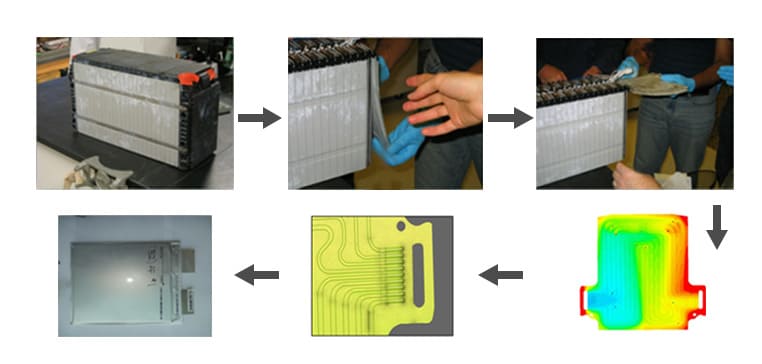

Reverse Engineering & Benchmarking

DEP specializes in reverse engineering of existing components. Our adept engineers meticulously deconstruct and analyze hardware to grasp its design and functionality comprehensively. This enables us to enhance or replicate components with superior performance, providing impactful solutions for competitive benchmarking. DEP offers an inclusive benchmarking analysis to empower customers with a strategic advantage in future product development.

Our advanced benchmarking process delivers scanned data and 3D CAD models, augmented by correlated Finite Element, CFD, and 1D models, offering unique value additions.

Key offerings:

Teardown, Benchmarking and Digitizing

High-quality parametric 3D CAD model generation from scan data.

High-quality CAE model generation from reverse-engineered CAD.

Correlated and Parametric CAE models as part of the benchmarking process.

Advanced 3D and CT Scanning

CAD Modeling: Create detailed digital models from scanned data.

Comprehensive Material Analysis: Understand component properties thoroughly for effective benchmarking and enhancement.

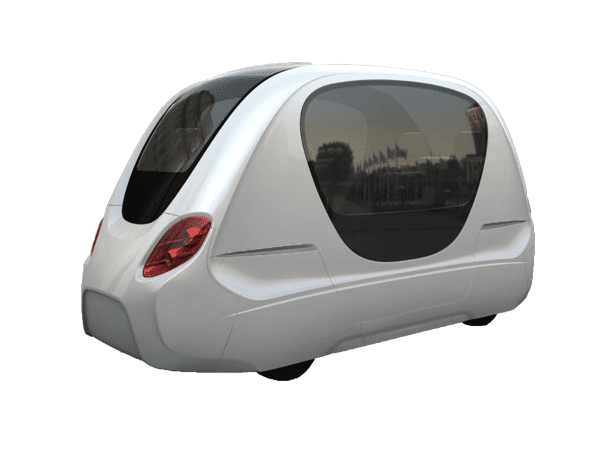

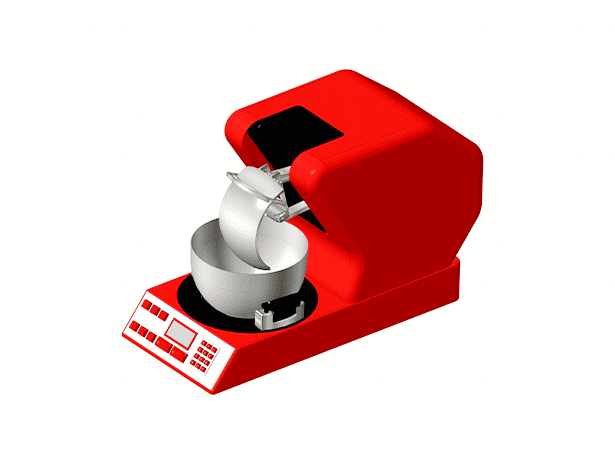

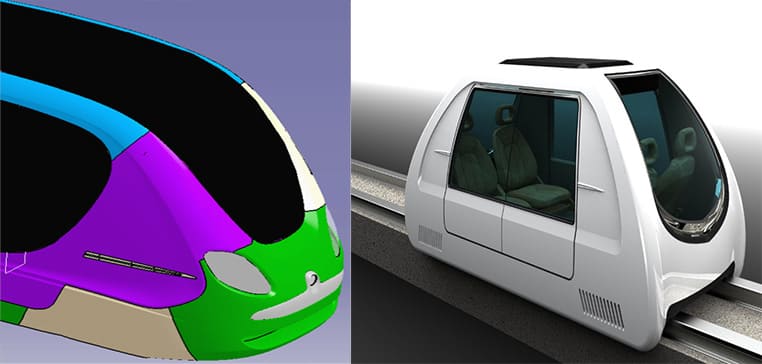

Concept and Concept Development

Every great hardware solution begins with a solid concept. DEP works closely with clients to understand their unique needs and challenges, translating these insights into innovative hardware concepts.

Key offerings:

Styling & Conceptualization

Concept CAD

Realistic rendering to Mockup evaluation

Clay modeling

Surfacing of the selected concept

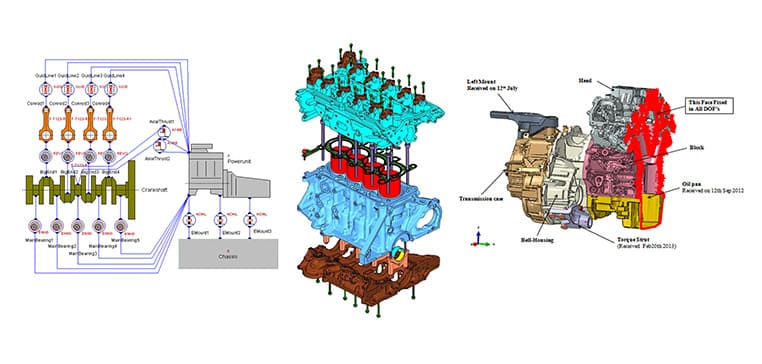

System Engineering

System Engineering is an interdisciplinary approach utilized across various industries to ensure the effective design, development, and maintenance of complex systems. At DEP, we transform an idea into a finished product or system. It involves integrating various subsystems and components to function cohesively. DEP offers comprehensive systems engineering services that encompass innovation, concept, and product development phases, with a focus on the holistic system level.

Key Offerings:

Conceptualize and create system architecture design.

Develop models and evaluate designs.

Model Based System Engineering (MBSE)

Modeling & Simulation:

Finite Element Analysis (FEA)

Integration

Combine subsystems and components into the main system.

Ensure compatibility and interaction between subsystems.

Verification & Validation:

Automated Testing

Hardware in Loop (HIL)

Software in Loop (SIL)

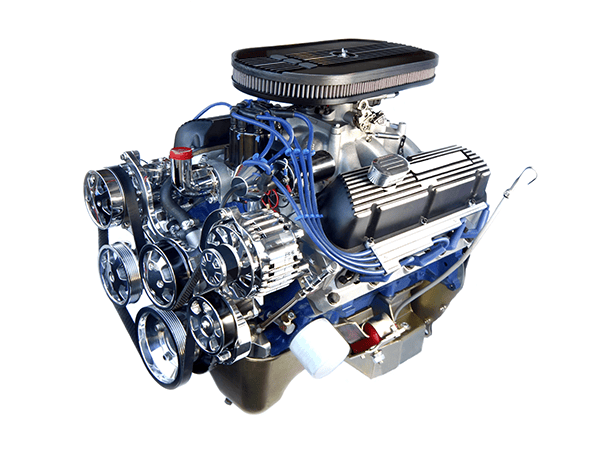

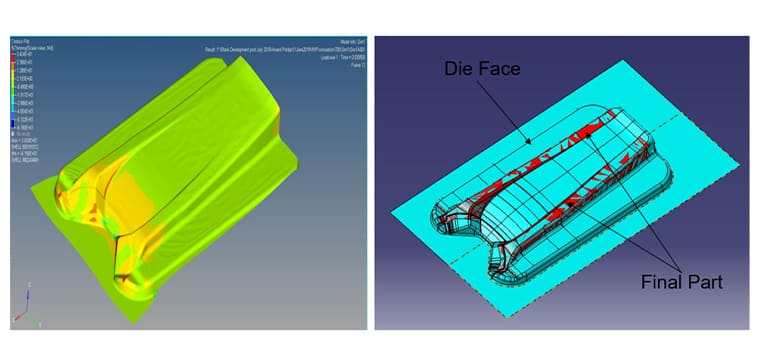

Detailed Design in Engineering

Detailed design is the phase where comprehensive and precise specifications are developed for all aspects of a project. This includes creating detailed CAD models, selecting materials, defining dimensions, and specifying tolerances. It ensures that all components fit together properly and function as intended, forming the basis for manufacturing and assembly.

Key Offerings:

Technical sections

Styling/graining data

CAD data

GD&Tdrawing

Tooling

Off tool parts

IP assembly drawings

DFMEA (Design Failure Mode Effective Analysis)

Tolerance stack up

DFM Simulations, DFM, Process planning for cost estimation

2D Drawings with GD&T

Final Prototype

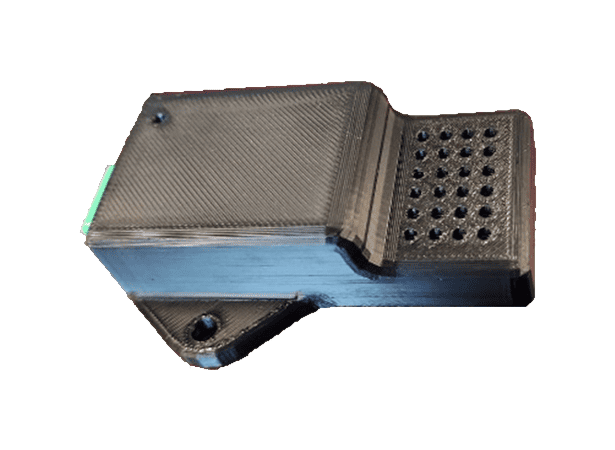

Rigorous Testing and Prototyping

DEP's commitment to quality is reflected in our rigorous testing and prototyping procedures. We create detailed prototypes to evaluate the design's performance, durability, and manufacturability. Through extensive testing, we ensure that each hardware component meets stringent quality standards and performs reliably in real-world applications.

Key Offerings:

3D printing

Environmental testing

Durability Testing: Durability/Fatigue

Safety Testing: Crash, Seatbelt: Safety

Performance Testing: Engine, Brake, and Suspension

Aerodynamic testing

Acoustic Testing: NVH

Materials Testing

Bench Testing

System Integration

Durability Testing

Simulation Testing

Related Services

DEP covers product engineering across a wide range of industries, providing innovative solutions for automotive, aerospace, healthcare, industrial equipment, and more.

Why Us?

End-to-end product development support, from concept to production

Access to a team of seasoned engineering professionals

Utilization of cutting-edge technology and tools with MeshWorks

Commitment to high-quality, innovative, and cost-effective solutions

Proven track record of successful projects across various industries

Customizable solutions tailored to meet specific client needs

Streamlined project management ensures timely delivery and adherence to budget