Benchmarking & Reverse Engineering

Benchmarking-Driven Reverse Engineering for Product Validation

Due to technological advancements, today’s competitive market is dominated by innovation and its rapid implementation. As an engineering technology firm, DEP provides reverse engineering services for any product or equipment, allowing you to improve design while monitoring manufacturability and the development process. Our qualified engineering team has gained extensive experience in reverse engineering projects over the last few years. Furthermore, our cutting-edge software tools ensure that the physical object models are ready for analysis, design optimization, or manufacturing. Many organizations choose us as a partner because of our expertise in various disciplines such as design validation and optimization, finite element analysis, and product engineering. We provide reverse engineering support to customers at all stages of product development to determine the original design intent, modernize manufacturing processes, or design a new part to fit a legacy part, among other things.

Understanding the purpose of the component or assembly is critical to every reverse engineering technique. DEP’s qualified engineers employ numerous geometric and tolerance methodologies to stack tolerances and have experience based on actual design work to illustrate the efficacy of the process. All these processes are based on the understanding of how the part/assembly interacts with other components in the system. DEP provides reverse engineering service to customers at various stages of product development to establish the original design intent, modernize manufacturing processes, or create a new part to fit a legacy part, etc. Using the most up-to-date abilities and technologies, our experts can deliver ideal solution tailored to each client’s specific needs.

Services

- Bench Marking

- 3D CAD Model

- Optimized Design

- Competitive Bench Marking

- Reverse Engineering

- Blended Scanning

- 3D Scanning

- (VAVE) Technology

- Material Testing

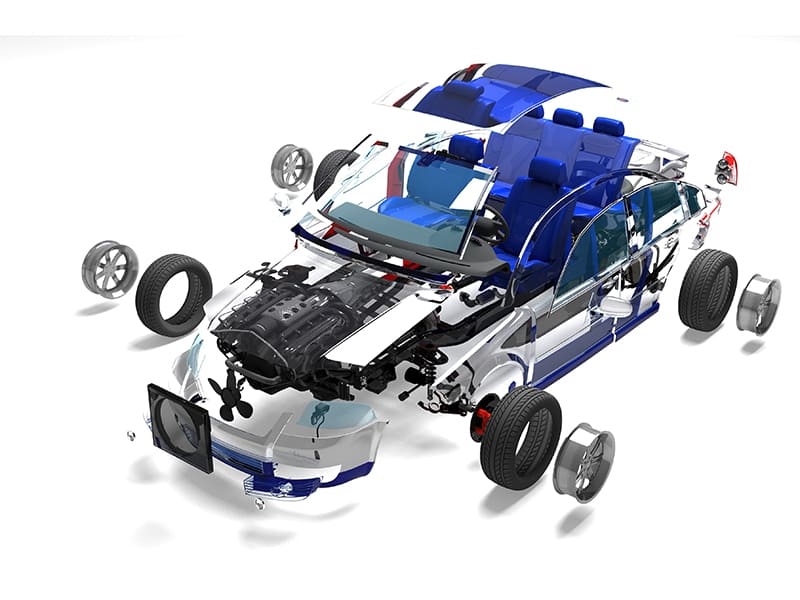

Teardown, Benchmarking, and Digitizing

This process involves dismantling a product to analyze its components and functionality. Benchmarking compares these findings with competitors’ products to identify strengths and weaknesses. Digitizing converts the physical components into digital models, enabling further analysis and design improvements.

DEP Capabilities:

3D Scanning

Industrial CT Scanning

High-Quality Parametric 3D CAD Model Generation

High-quality CAD models are created from scanned data or reverse-engineered designs. These parametric models are editable and can be used for design optimization, simulation, and further product development.

DEP Capabilities:

High-quality parametric 3D CAD model generation from scan data

High-quality CAE model generation from reverse-engineered CAD

Finite Element models

CFD models

1D system models

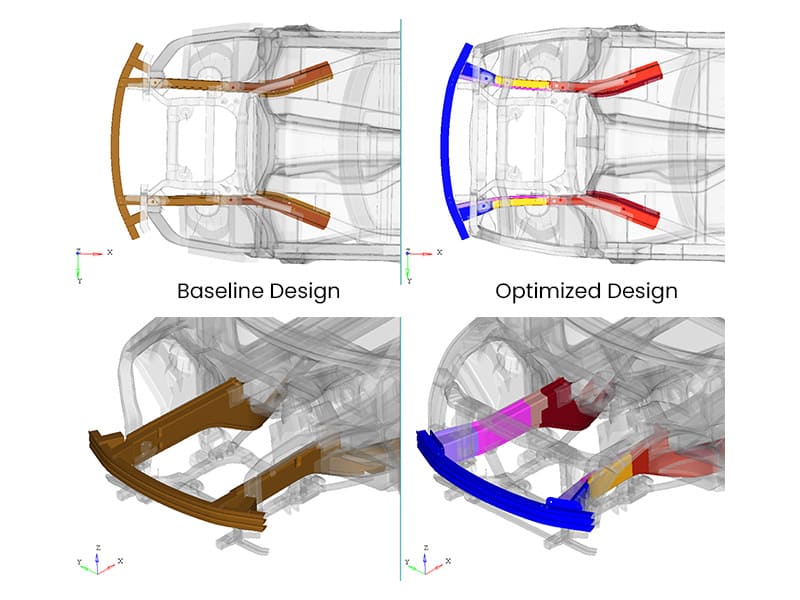

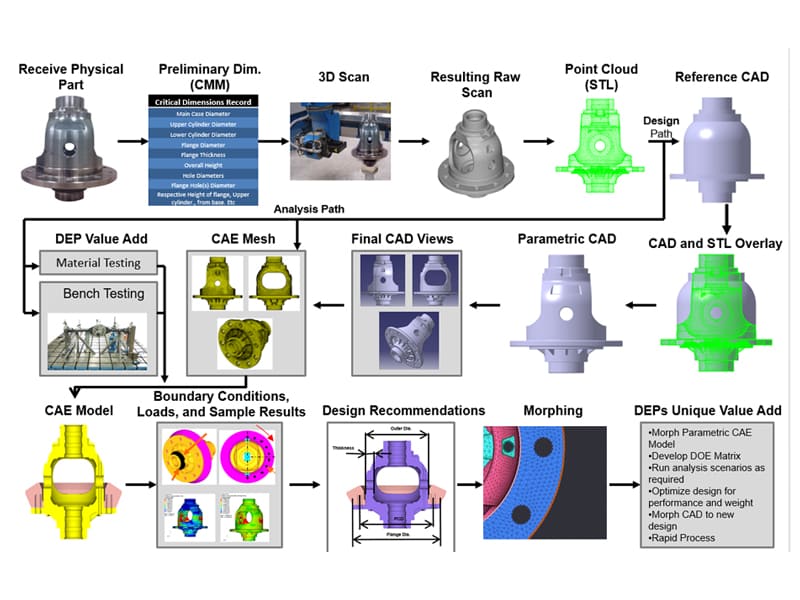

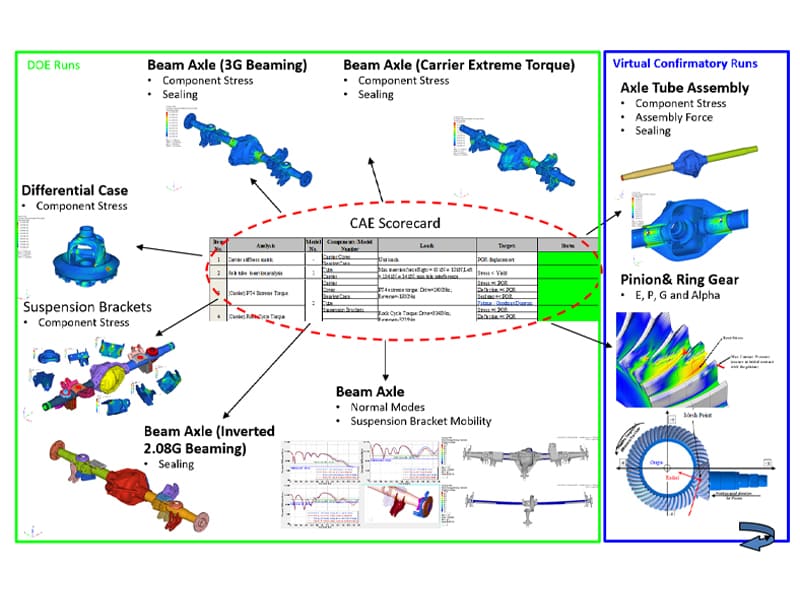

Optimized Design with Correlated and Parametric CAE Models

Correlated CAE models are developed during the benchmarking process to simulate and analyze product performance. These models undergo physical validation to ensure accuracy, making them highly reliable for design refinement and optimization. On the other hand, parametric CAE models enable rapid design iterations by allowing modifications to existing models, facilitating the exploration of new design possibilities based on benchmarking data. This combination accelerates the development process, ensuring efficient and informed design decisions.

DEP Capabilities:

Correlated CAE models

Flow-Bench, Particle Image Velocimetry (PIV), and Dyno-Lab test to correlate models

Parametric FE & CFD models of competitor parts, using which new designs can be generated rapidly

Reverse Engineering/Competitive Benchmarking

Reverse engineering involves analyzing an existing product to understand its design and functionality. This process is used to recreate, improve, or develop new products based on the analyzed data.

DEP Capabilities:

Part Scanning Services

Computer- Aided Verification (CAV)

Benchmarking Services

Detailed Part Specifications Services

Other analysis supports – Manufacturability, Design for Manufacturing and Assembly, Material analysis, etc.

Modeling support

Providing CAD data that specifies the original design intent of an object.

Detailed geometric/dimensional analysis.

Redesigning parts without manufacturing defects.

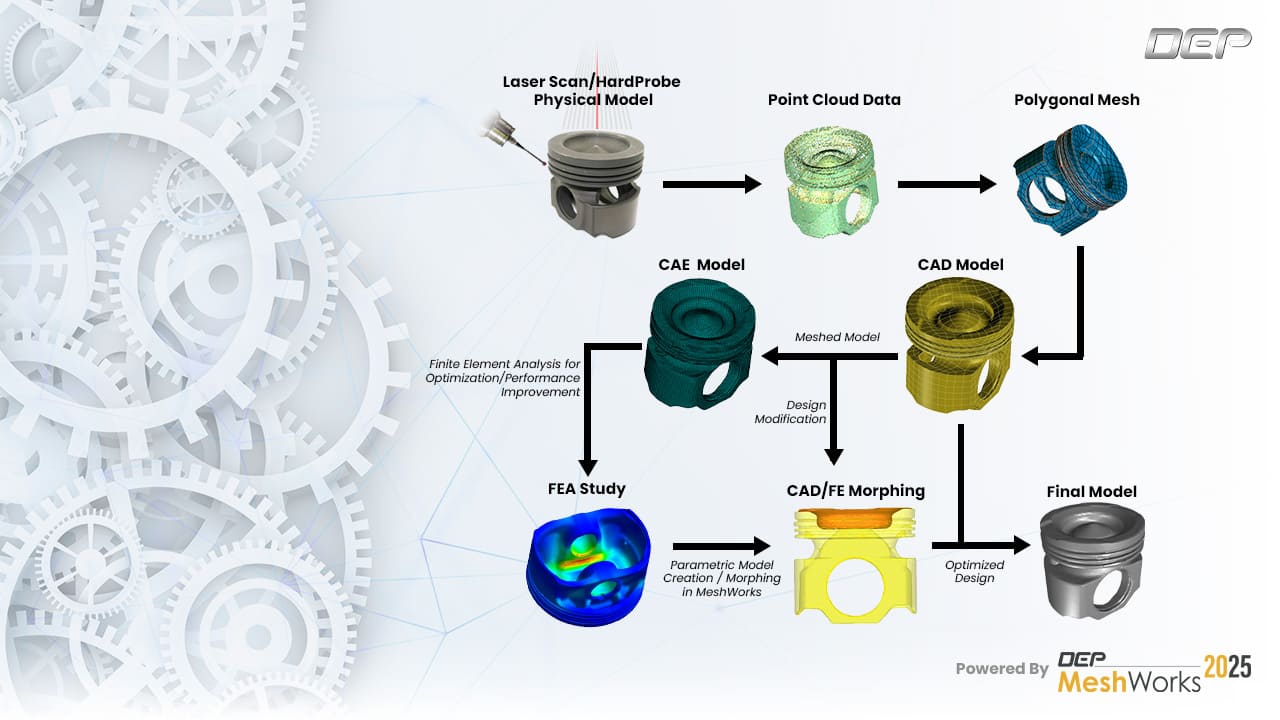

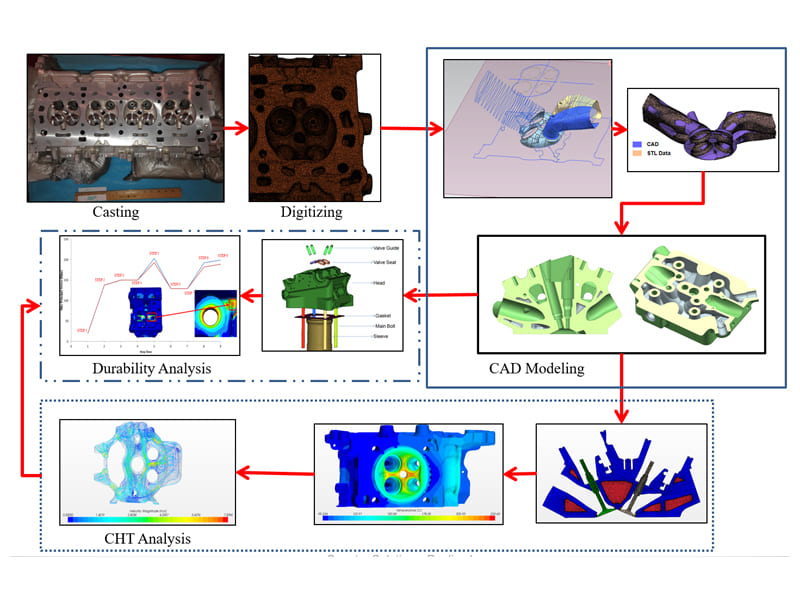

Reverse Engineering Process Flow

This outlines the step-by-step process of reverse engineering, from capturing the geometry of a physical model to finalizing a digital model suitable for analysis and further development.

DEP Capabilities:

Laser scan/hard probe physical model

Point cloud data

Polygonal mesh

CAD model

CAE model

CAD/FE Morphing

FEA study

Final model

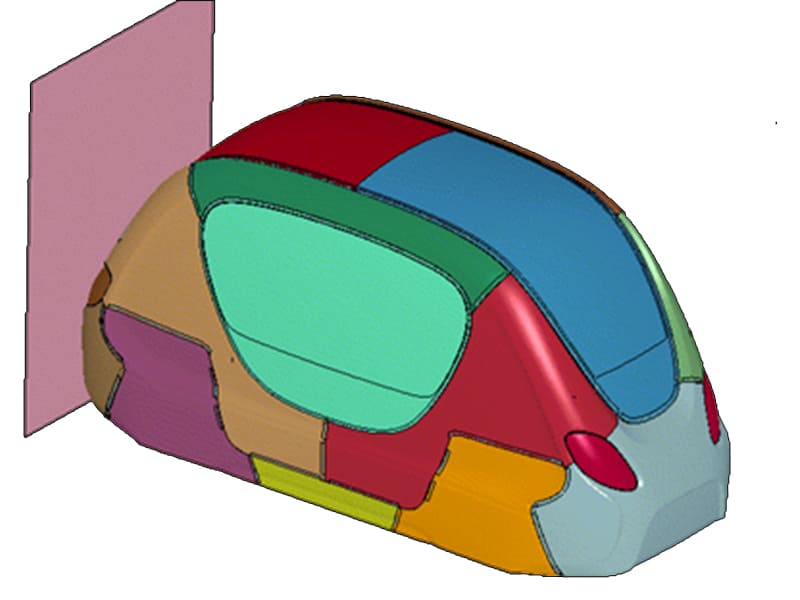

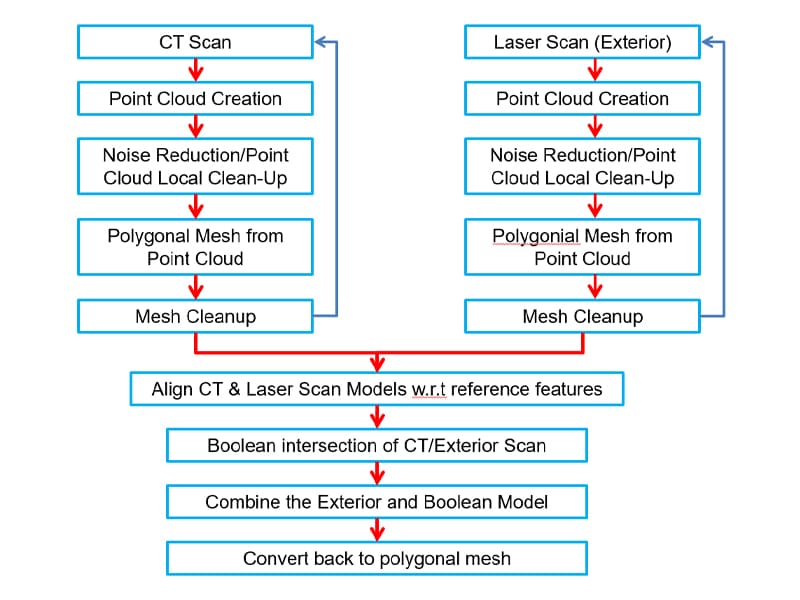

DEP’s Blended Scanning Process

This process combines various scanning methods to create comprehensive digital models that include both internal and external features of a product. The result is a highly accurate representation that can be used for detailed analysis and design work.

DEP Capabilities:

CT scan & Laser scan (exterior)

Point Cloud Creation

Noise Reduction/Point Cloud Local clean-up

Polygonal mesh from Point cloud

Align CT & Laser scan models with respective reference features

Boolean Intersection of CT/Exterior scan

Combine the exterior and boolean model

Convert back to polygonal mesh

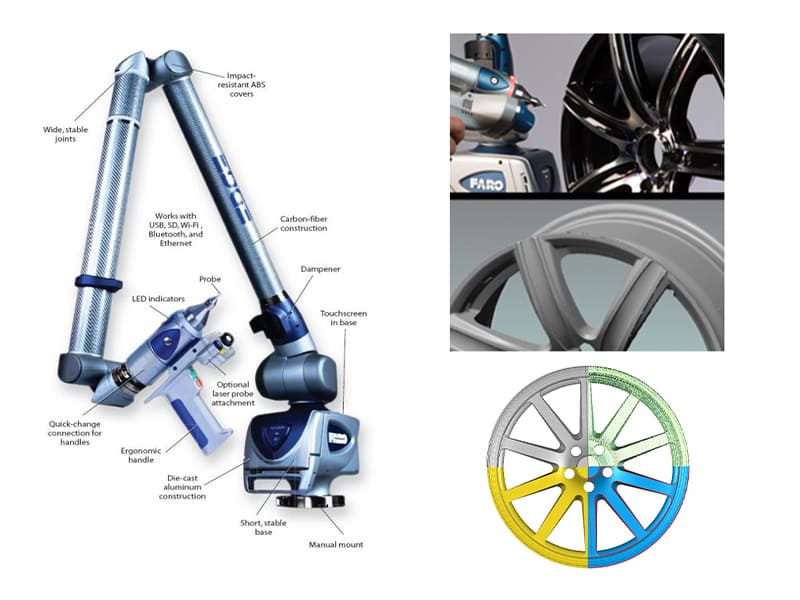

3D Scanning Methodology Technology

DEP’s advanced 3D scanning technology captures detailed geometric data from physical objects, allowing for precise reverse engineering, quality inspections, and design optimizations. This technology supports projects requiring high accuracy, providing efficient solutions for product redesigns, quality assurance, and delivering reliable data for design optimization.

DEP Capabilities:

Laser Scanning

CT Scanning

3D Point Cloud Processing

Value Analysis & Value Engineering (VAVE) Technology

DEP’s Value Analysis and Value Engineering (VAVE) technology focuses on optimizing product designs and processes by maximizing value while reducing costs. Through the application of benchmarking and reverse engineering, this technology identifies cost-reduction opportunities, improves performance, and fosters innovation, ensuring enhanced overall value for customers.

DEP Capabilities:

CAE and Simulation

Design Enhancement

Material Optimization

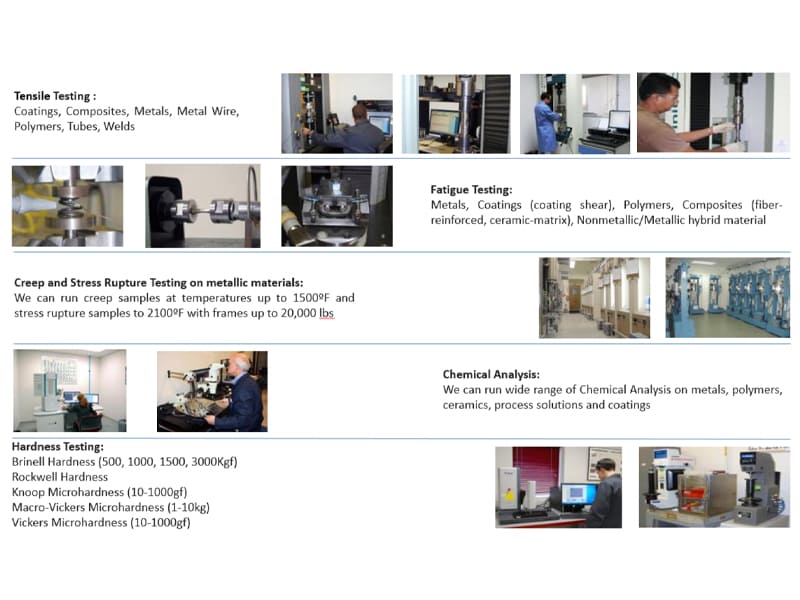

Material Testing – Thermo-Mechanical

Material testing assesses the physical properties of materials under different temperatures and mechanical stresses. This information is crucial for ensuring that materials will perform reliably in their intended applications, especially under extreme conditions.

DEP Capabilities:

All the tests carried out at wide range of temperatures (-60 to 300°C)

Tensile tests

Compression tests

Bend tests

DEP Value Addition

3D Laser scanning technology to capture physical parts accurately

Scalable services to ramp up engineering requirements

Comprehensive reports and insights about the product feature

Decades of experience in actual design work to verify the efficacy of the process

Manufacturing support through prototyping and other modernization activities

Application Domains

Why Us?

At Detroit Engineered Products, we excel in benchmarking and reverse engineering by leveraging advanced 3D laser scanning and decades of design expertise. Our scalable solutions deliver in-depth analysis, actionable insights, and customized support, ensuring precise data for enhanced product performance and competitive market adaptation.

Precision with Advanced 3D Laser Scanning: We employ cutting-edge 3D laser scanning technology to capture even the most complex physical parts with high accuracy, ensuring that the reverse engineering process is based on reliable data.

Scalable Engineering Solutions: DEP offers scalable services that adapt to your growing engineering requirements, ensuring that we can support your projects, regardless of size or complexity.

In-Depth Analysis and Comprehensive Reporting: Our reverse engineering process provides thorough reports and insights into the product’s features, helping you understand and improve your designs.

Decades of Design Experience: With years of hands-on design experience, DEP’s team can verify the efficacy of reverse-engineered components, ensuring that they meet the required performance standards.

Support for Modern Manufacturing: We extend our services beyond reverse engineering to include manufacturing support, such as prototyping and modernization activities, to help bring your product to market efficiently.

Customized, High-Quality Services: Our experienced professionals deliver top-quality services tailored to your specific needs, ensuring that the benchmarking process provides actionable insights.

Consultative Problem-Solving Approach: DEP’s consultative approach goes beyond just data gathering; we work with you to identify areas for improvement, providing solutions that can enhance product performance and competitiveness.

Enhanced Simulation Capabilities: We provide data that can be integrated into various simulation processes, allowing for more accurate testing and optimization of your product designs.

Cost-Effective Product Development: Our methodologies are designed to save you time and money, helping you bring optimized products to market faster.

Agility in Market Adaptation: DEP helps your product stay ahead of market trends by optimizing quality and processes, ensuring that your offerings remain competitive in a dynamic marketplace.