Model Building

Precision-Driven Modeling for Enhanced Engineering Simulations

InnovativeModels,Proven Results

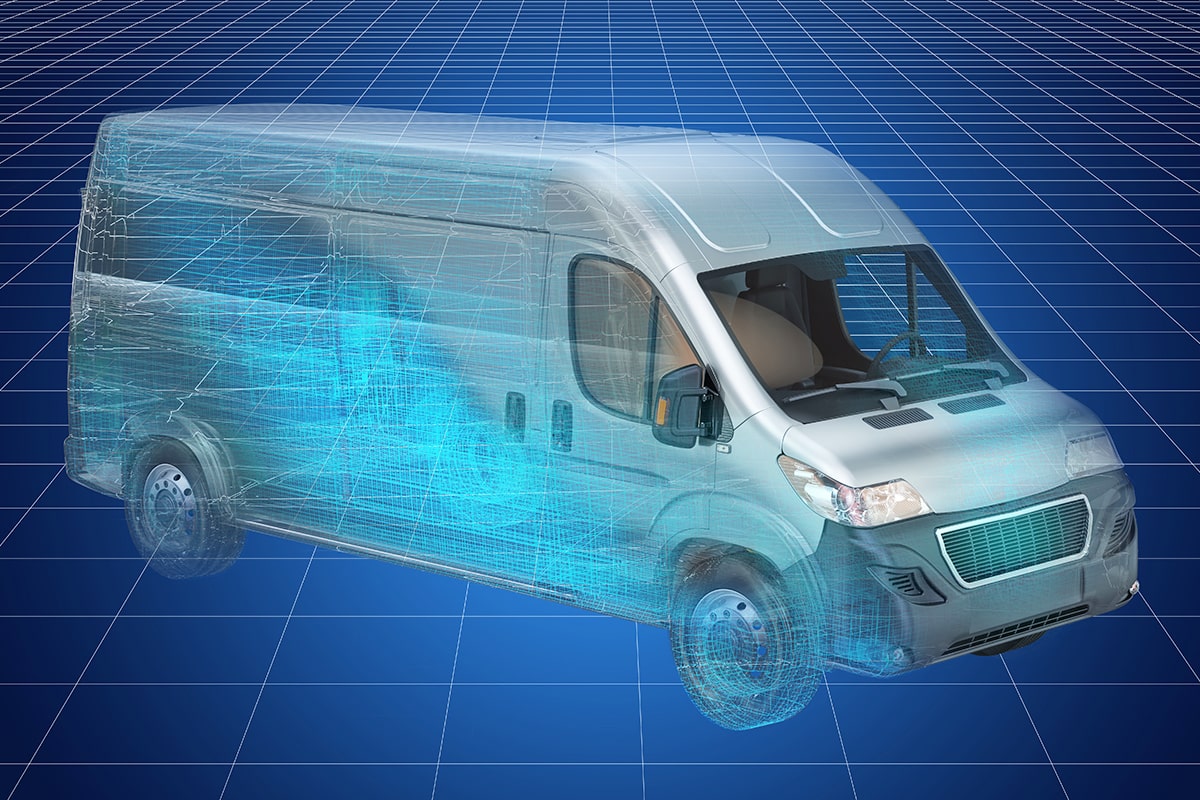

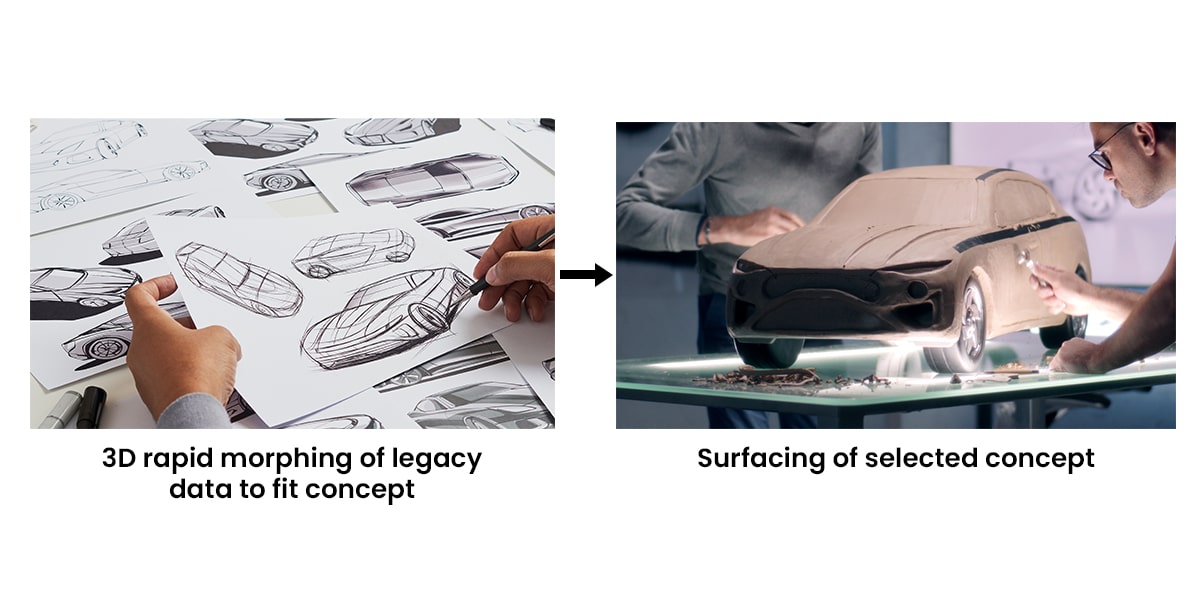

Model building serves as the cornerstone of effective engineering analysis, focusing on creating precise digital representations of physical systems. This process encompasses defining modeling concepts, assembling components, assigning material properties, and other essential steps to ensure accurate and reliable simulations. Validation is a crucial step to confirm the model's reliability and alignment with real-world performance, paving the way for effective decision-making in design and development.

At Detroit Engineered Products (DEP), we streamline and enhance the model-building process with our advanced tools, methodologies, and expertise. Our proprietary MeshWorks platform integrates sophisticated modeling concepts, automated meshing, and material property optimization to create reliable, high-quality models. By reducing manual effort and accelerating validation, MeshWorks enables rapid iteration, from component-level analysis to complex assembly modeling. This ensures models closely align with real-world performance while meeting stringent safety and regulatory standards. DEP empowers clients to overcome design challenges, optimize performance, and achieve faster, more accurate simulations across diverse industries.

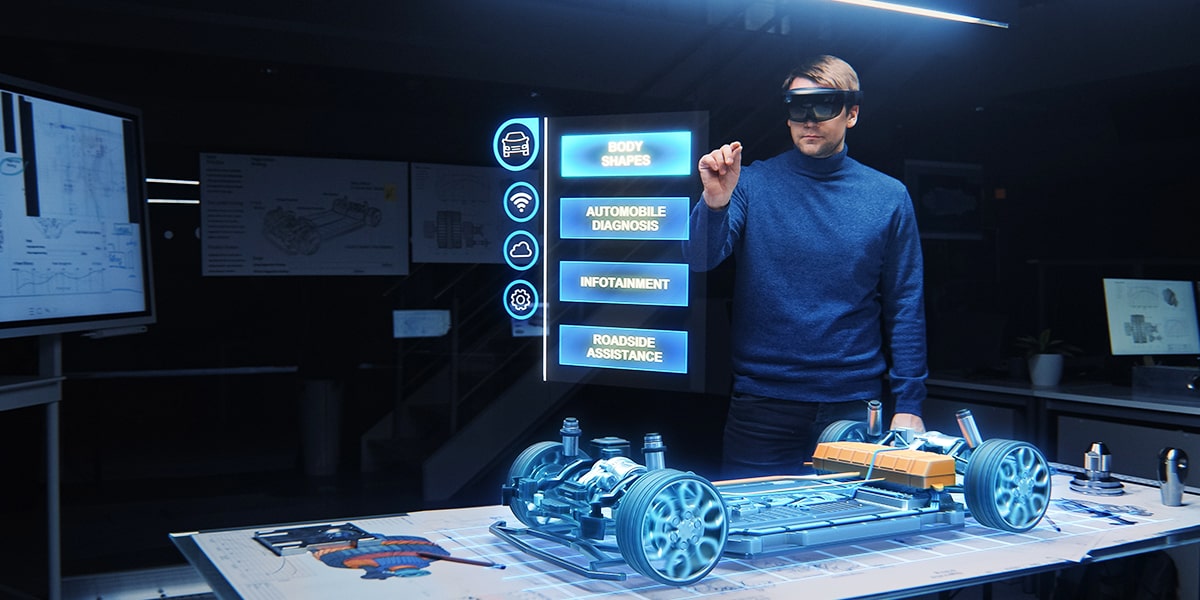

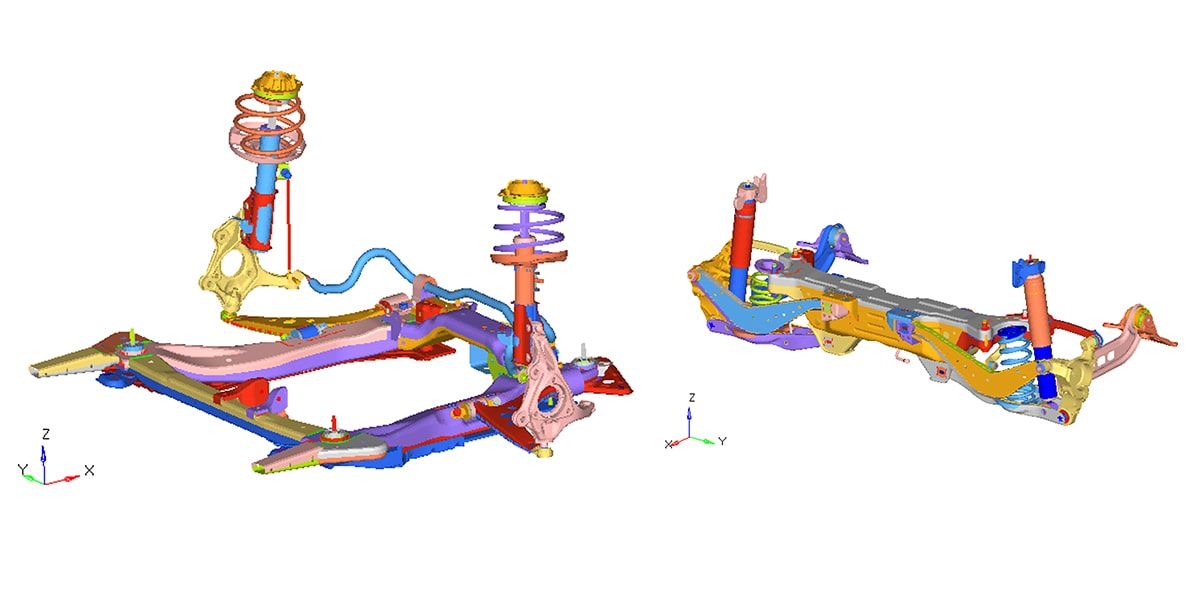

Modeling Concepts & Assembly

We focus on crafting precise modeling concepts that capture the intricacies of complex physical systems. Our approach optimizes component assembly, ensuring effective analysis and smooth integration for advanced digital simulations.

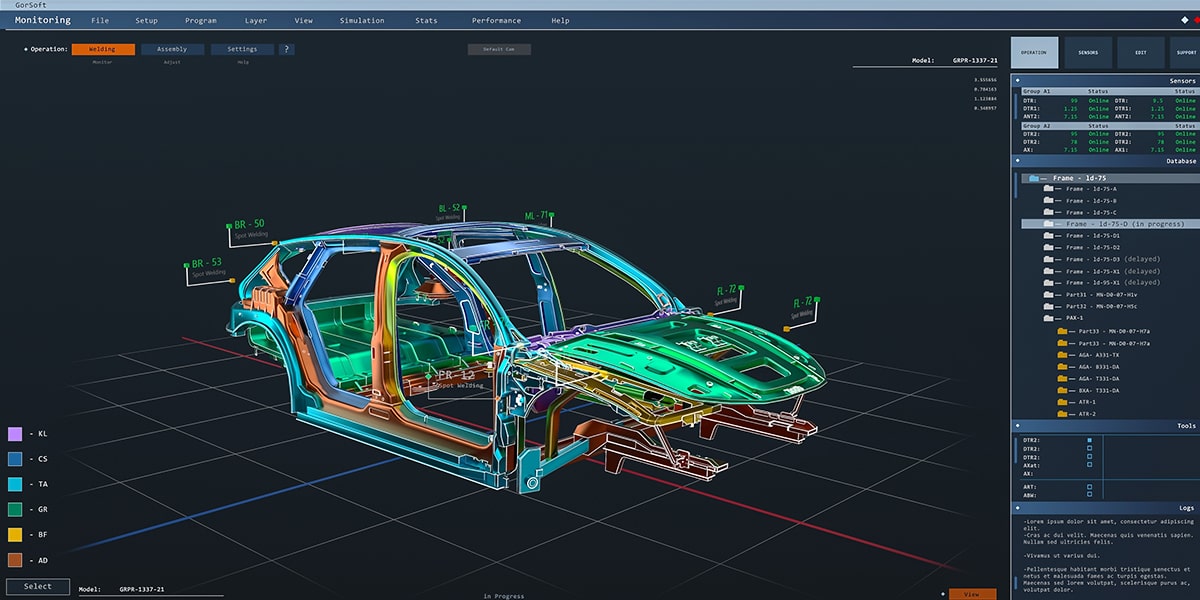

Modeling Parameters (Meshing &

Connections)

Our expertise in meshing and defining connections guarantees high-quality simulations. We apply advanced meshing techniques and precise connection strategies to ensure accurate representation of physical behavior and reliable simulation results.

Model Validation

We conduct thorough model validation to verify the accuracy and reliability of our digital models. By comparing simulation results with experimental data, we ensure that the model behaves as expected, meeting all performance and safety requirements.

Material Properties

We optimize material properties to accurately reflect the characteristics of real-world materials in simulations. By assigning the correct properties, we ensure that models perform reliably under varying conditions, from stress tests to thermal analysis.

Modeling Concepts & Assembly

Development of 2D and 3D conceptual models for components and assemblies

Detailed assembly modeling for accurate representation of mechanical systems

Parametric and feature-based modeling to support design flexibility and modifications

Kinematic and dynamic simulation-ready model creation

Integration of multi-disciplinary attributes (structural, thermal, fluid, and electrical) into models

Tolerance and fit analysis for precise assembly and manufacturability

Rapid prototyping and virtual validation of assembly concepts

Optimization of assembly layout for performance, weight, and cost efficiency

Seamless integration with CAD/CAE workflows for downstream analysis

Meshing & Connection Pre-Processing

High-quality, optimized meshing for accurate and efficient structural, thermal, and fluid simulations

Definition and management of connections (joints, bolts, welds, contacts, interfaces) with realistic load transfer

Parametric modeling of meshes and connections to support design variations and optimization

Seamless CAD/CAE integration for complex assemblies and large models

Multi-disciplinary setup ensuring readiness for static, dynamic, and fatigue analyses

Rapid iteration, validation, and refinement for reliable simulation results

Model Validation:

Verification of simulation models against theoretical and experimental data

Correlation of CAE results with physical test results for accuracy

Identification and correction of modeling errors, boundary conditions, and assumptions

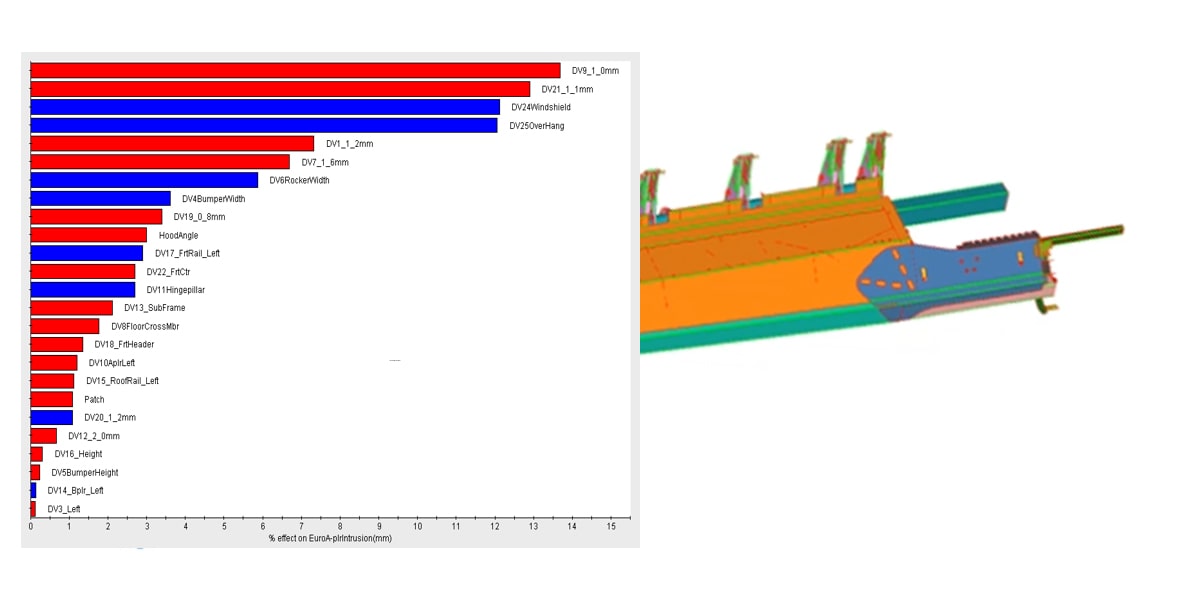

Sensitivity analysis to evaluate model robustness and reliability

Validation of structural, thermal, fluid, and multi-physics simulations

Iterative refinement of models for improved predictive capability

Support for prototype and full-scale testing validation

Integration with CAD/CAE workflows for seamless model updates

Documentation of validation results for compliance and reporting

DEP Advantages

We provide exceptional CAE Services and our commitment to provide industry leading System Simulation (1D-CFD) to the global clientele has continued to strengthen our reputation, making us the chosen partner for engineering service in the market. We promise you the advantage of:

Quality Service

Expert Support

Custom Tailored Solutions

Advanced Technology

Timely Delivery

Competitive Rate