Concept Design

Next-Generation Concept Design Enabled by Digital Engineering

The nature of product design is changing rapidly. Customers expect sophisticated customization, while disrupted supply chains require alternate sources for materials and components. Manufacturers are under increasing pressure to maximize agility and minimize waste. Design was traditionally driven by human experience and creativity, with technology playing a limited role via discrete tools. But recent tech advancements have started to dramatically shift the role of technology in the design process.

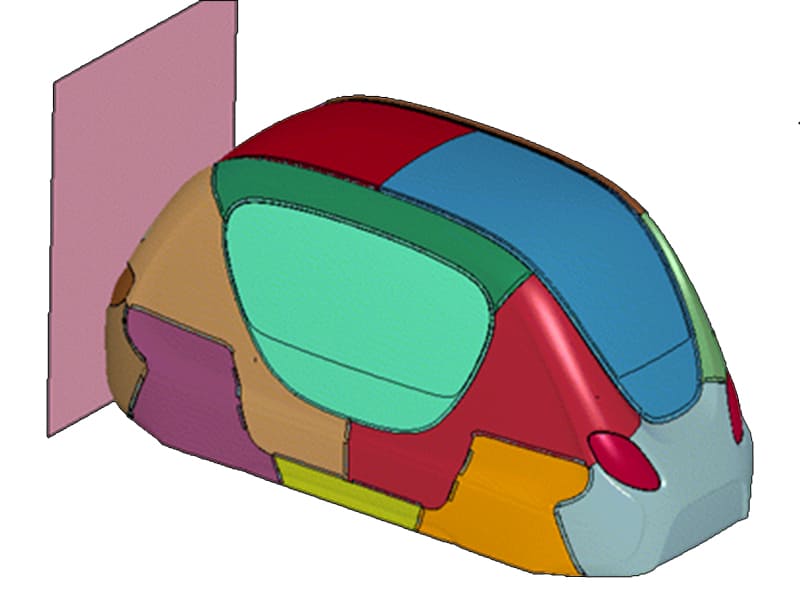

MeshWorks, DEP’s flagship product, is an ideal tool for concept design studies of products such as automobiles, trains, aircrafts, and industrial products such as power tools and appliances. Concept design activities entails both structural and aesthetically pleasing work. To that end, the MeshWorks’ Computer Aided Surfacing module is a powerful tool for comparing two or more exterior design alternatives for a vehicle or product in order to assess aesthetic appeals.

Services

- Concept Design

- 3D Concept Modeling

- Virtual Prototyping

- Design Optimization

- Material Selection

- Design Verification

Concept Design

DEP's Concept Design Service harnesses cutting-edge simulation tools and capabilities to validate and optimize early-stage designs, ensuring maximum efficiency and peak performance. Our expertise in 1D and 3D simulations, coupled with advanced modeling techniques, allows us to accurately predict system behavior and accelerate the transition from concept to reality.

DEP Capabilities:

Conceptualization

Concept styling development

Clay modeling

Virtual Prototyping

Failure Mode and Effects Analysis (FMEA)

3D Concept Modeling

DEP offers advanced 3D CAD and surface modeling services to transform initial ideas into detailed and aesthetically refined digital models, enabling precise visualization and evaluation of design concepts.

DEP Capabilities:

CAD Modeling

Surface Modeling

Parametric Design

Visualization

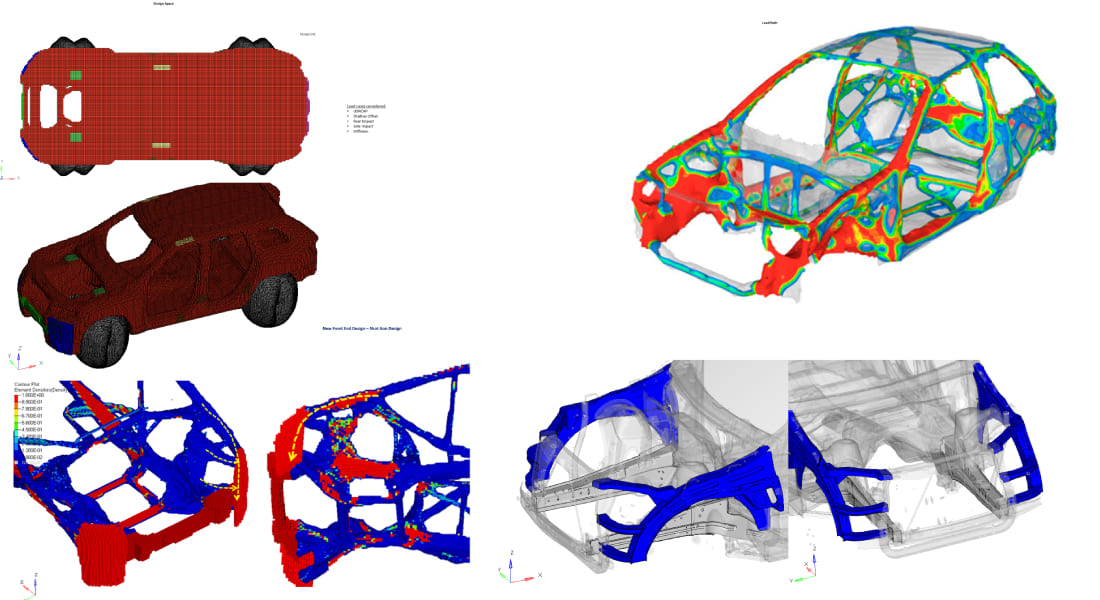

Virtual Prototyping and Simulation

DEP leverages cutting-edge simulation tools, including FEA, CFD, and dynamic analysis, to create virtual prototypes that predict real-world performance, minimizing the need for physical prototypes and reducing development cycles.

DEP Capabilities:

FEA

CFD

Dynamic Analysis

Thermal Simulation

Crash Simulation

Design Optimization

DEP’s design optimization services use topology and multi-disciplinary optimization techniques to enhance design efficiency, reduce material usage, and balance performance objectives, resulting in innovative and cost-effective solutions.

DEP Capabilities:

Topology Optimization

Multi-disciplinary Optimization

Weight Reduction

Material Selection and Analysis

DEP provides material modeling and composite analysis to help clients select the best materials for their designs, optimizing properties like strength, weight, and durability for superior product performance.

DEP Capabilities:

Material Modeling

Composite Analysis

Fatigue Analysis

Material Testing

Design Verification and Validation

DEP’s virtual testing and design iteration services validate the design under various conditions, ensuring reliability and functionality before moving to the physical prototyping stage.

DEP Capabilities:

Virtual Testing

Design Iteration

Stress Analysis

Compliance Testing

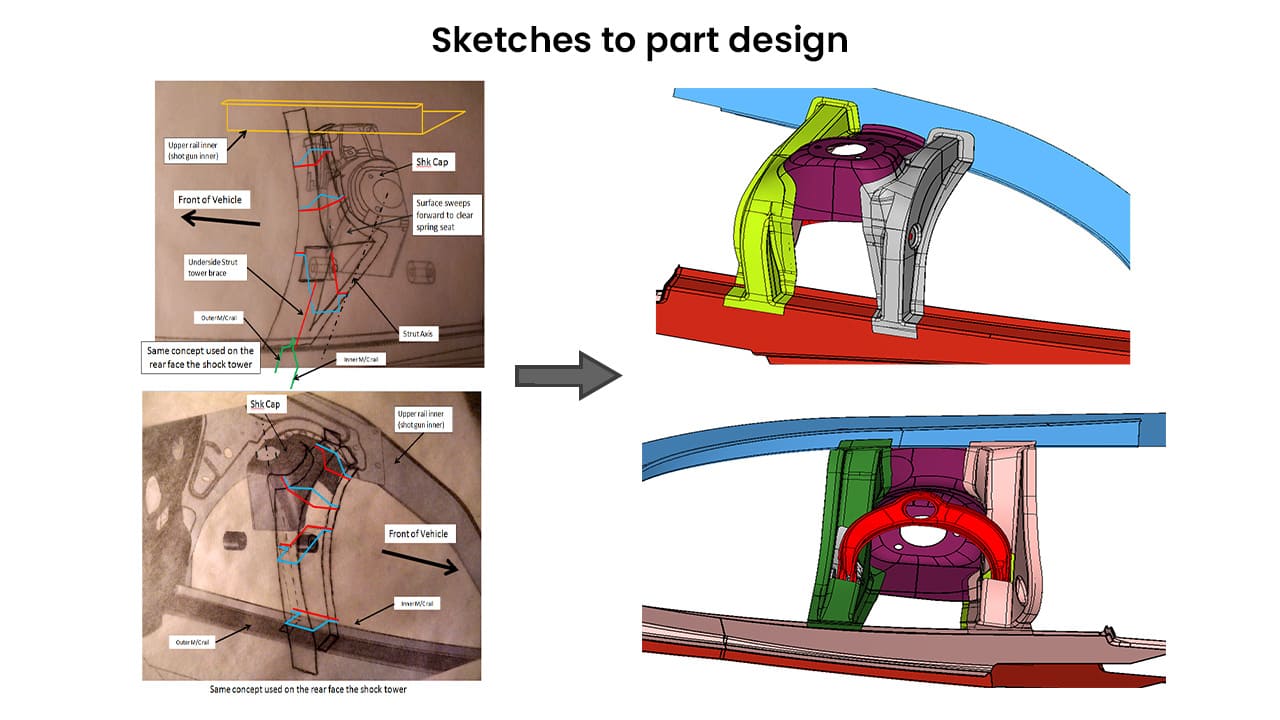

DEP Value Addition

Morph a legacy Finite Element (FE) mesh or legacy CAD data to new design styles

Eliminates the costly CAD-FE-CAD iteration cycles

Modify designs to do what-if studies at higher pace

Application Domains

Why Us?

At DEP, we’re committed to transforming the conceptualization phase into a streamlined and efficient process, integrating technical essentials seamlessly. Here’s how our solutions benefit you

Enhanced Conceptualization

DEP MeshWorks optimizes the initial design phase, ensuring that technical aspects are effectively addressed from the start. This streamlined approach reduces effort and leads to significant financial advantages throughout the product development lifecycle.

Zero-CAD CAE Assemblies

Our ConceptWorks platform allows for the creation of complete CAE assemblies without the need for traditional CAD models, simplifying the design process and accelerating development.

AI-Driven Design Guidance

Our ML-based design advisors offer invaluable insights, helping you make informed decisions and refine designs with precision.

Rapid Evaluation with Reduced Order Models

Experience swift evaluations with our fast reduced order models, enabling quick iterations and accelerated project timelines.