Analytical Methods Development

Analytical Process Development with Physics-Based CAE Modeling

Analytical technique development is a persistent and interdependent process connected with the departments of R&D, quality control, and quality assurance. The robustness of methods should be considered throughout the early phases of method development because quality of the data ultimately helps to decide which method will be authorized. Analytical processes are crucial in the assessment and management of equivalence and risk. It aids in the development of product-specific acceptance criteria and seamless outputs having higher quality. Combining analytical and experimental methods in the upfront design and development stage has become a critical tool to cut down the product development and process time.

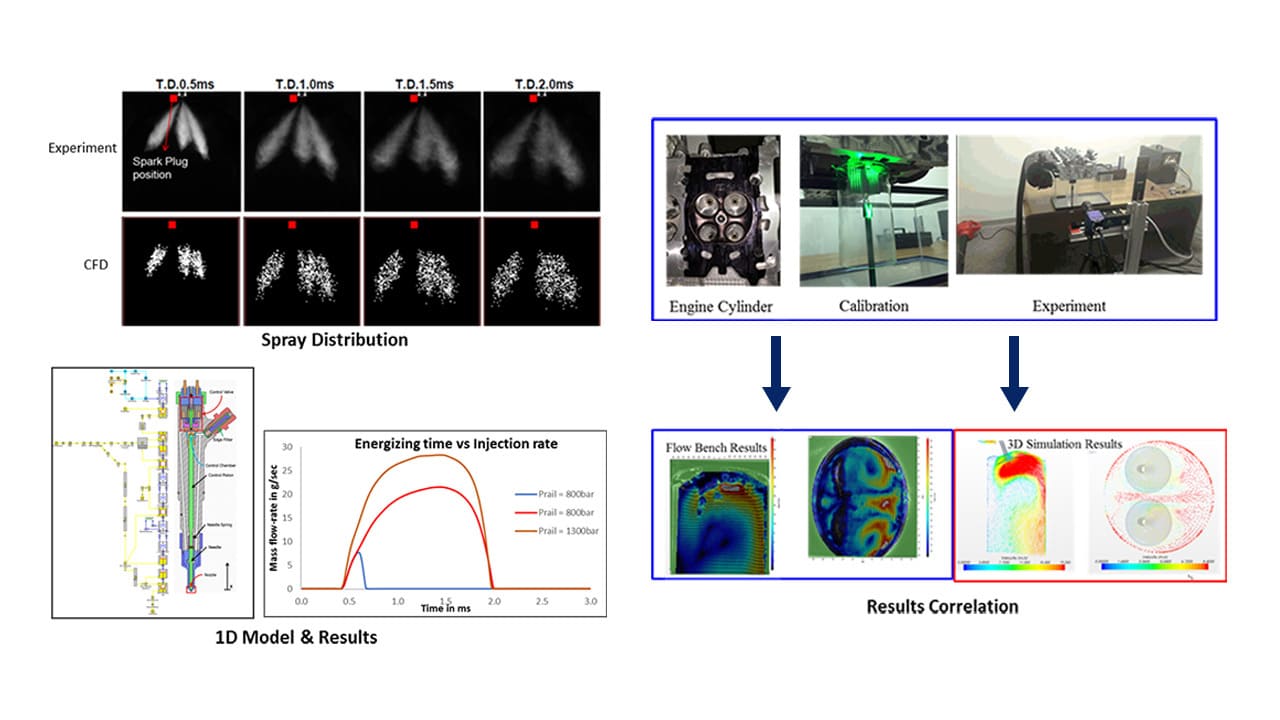

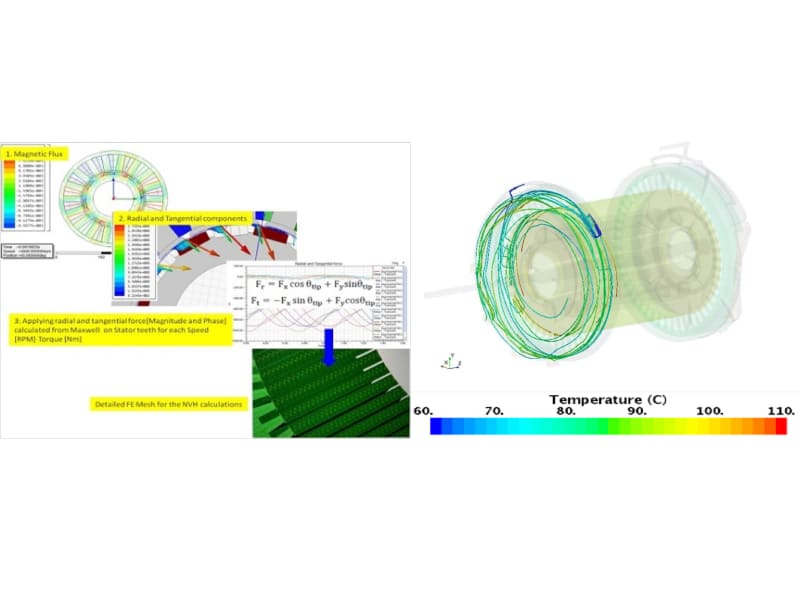

For various complex mobility systems, DEP developed reliable physics-based 1D and 3D CAE models. CAE models, real-time experiment calibration and simulation correlation, are also developed as part of this project.

Services

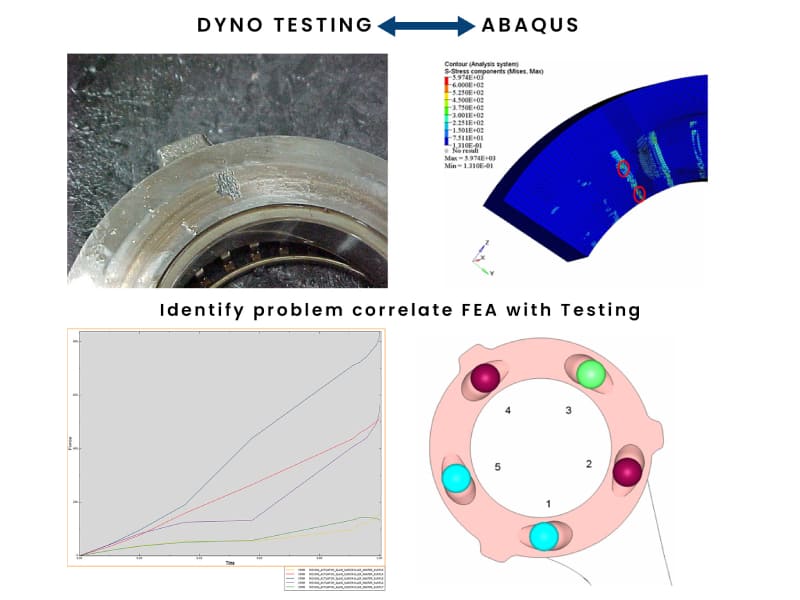

Performance Correlation Analysis

DEP provides services to correlate the results of one simulated test with another, ensuring consistency and accuracy across different simulation models. This process helps refine predictive models and improve design reliability.

DEP capabilities:

Finite Element Analysis (FEA)

Multi-Physics Simulations

Data Analytics

Correlation – simulation results

Digital Twin Technology

CFD Analysis (focusing on Combustion Procedures)

DEP specializes in Computational Fluid Dynamics (CFD) simulations with a focus on combustion processes. Their expertise in modeling combustion leads to optimizing engine efficiency, reducing emissions, and enhancing overall system performance.

DEP capabilities:

Computational Fluid Dynamics (CFD)

Heat Transfer Analysis

Thermal Management

Cooling Jacket Analysis

Piston and Cylinder Wall Interaction

Combustion Analysis

Airflow and Intake Optimization

Pressure drop analysis, Velocity distribution, Swirl and tumble motion inside the cylinders

CAE Evaluation of Automobile at System and Component Level

DEP conducts Computer-Aided Engineering (CAE) evaluations at both the system and component levels, using simulations to optimize performance, durability, and safety. This enhances product development by minimizing the need for physical testing.

DEP capabilities:

Finite Element Analysis

Structural Dynamics

Vibration Analysis

Fatigue Testing Models

Crash Simulation

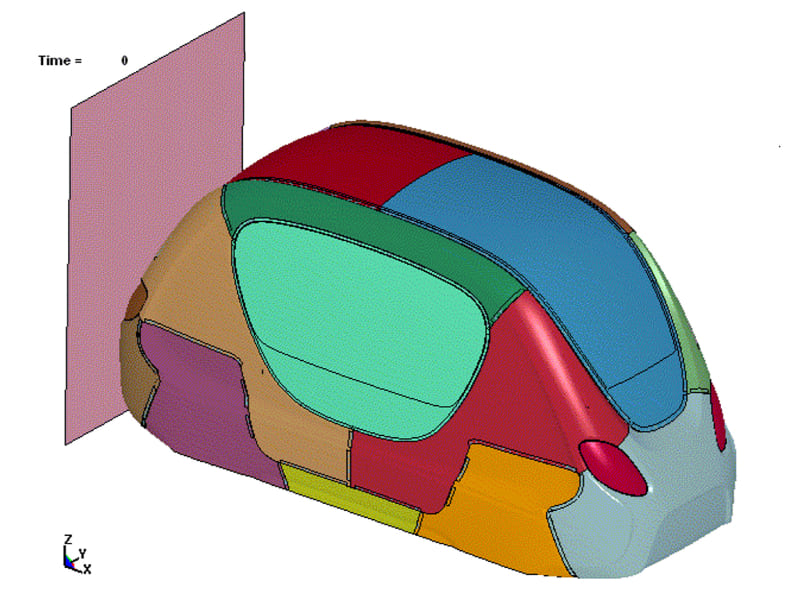

Complete CAD Data Management and Coordination on CAD Model Build

DEP specializes in the comprehensive management of CAD data throughout the model-building process. Their expertise ensures the creation of accurate and reliable CAD models, which accelerates the design process and enhances overall precision.

DEP capabilities:

Product Lifecycle Management (PLM)

Geometric Accuracy

Fit and Tolerance Analysis

Structural Analysis

Thermal Analysis

Dynamic Analysis

Fluid Dynamics Analysis

Targets Evaluation (vehicle level, system level, component level)

DEP evaluates performance targets at various levels, from the complete vehicle to specific systems and components. This ensures that designs meet performance benchmarks, regulatory requirements, and customer expectations.

DEP capabilities:

Performance

CAE Simulation

Benchmarking

System/Component Testing

DEP Value Addition

Data collation for a specific analytical problem from various sources.

Establishing accurate sensitivity parameters.

Explicit analyzing of factors affecting accuracy.

Performing specific Range of analysis required for the studies.

Maintaining precision data at all stages.

Analyzing consistency and durability throughout the development.

Application Domains

Why Us?

At DEP, we combine advanced analytical methods withcutting-edge engineering solutions to deliver unmatched efficiency and precision. From visual modeling and performance correlation analysis to comprehensive CAD and CAE evaluations, DEP ensures your designs areoptimized, reliable, and future ready. Trust DEP for innovative approaches that meet and exceed your engineeringobjectives.

Mitigate Future Risks

Ensure your methods are resilient and future-proof.

Optimized Pricing

Get the best value with our price optimization strategies.

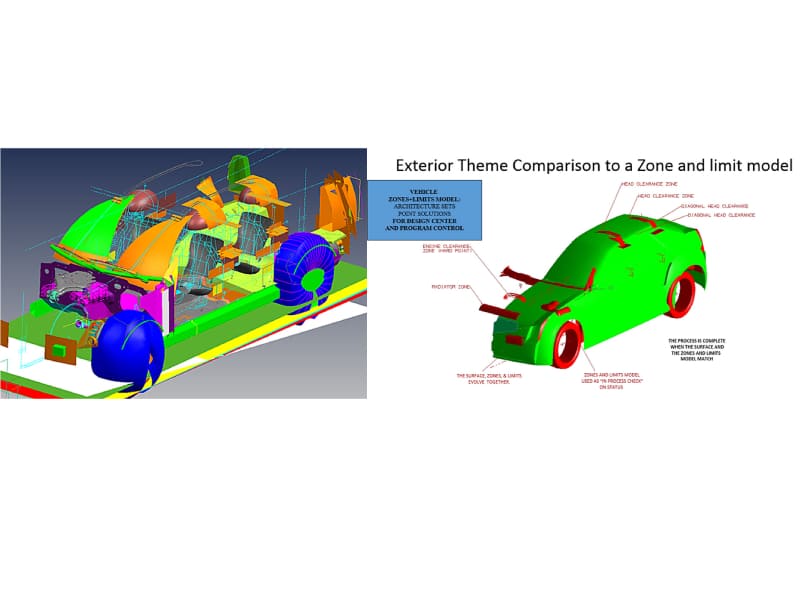

Advanced Visual Modeling

Benefit from our expertise in deriving models for superior visual environment rendering.

Performance Correlation Analysis

This service involves comparing and correlating performance data from simulations with experimental results to ensure accuracy and reliability in predictions.

CFD Analysis – Combustion Procedures

Focuses on analyzing and optimizing combustion processes within engines using Computational Fluid Dynamics (CFD) to enhance efficiency and reduce emissions.

CAE Evaluation of Automobiles (System and Component Level)

Provides comprehensive analysis and evaluation of both the overall vehicle and individual components using Computer-Aided Engineering (CAE) tools to assess performance, safety, and reliability.

Complete CAD Data Management and Coordination on CAD Model Build

Manages and coordinates all aspects of CAD data to ensure accurate and efficient model development and integration throughout the design process.

Targets Evaluation – Vehicle Level, System Level, Component Level

Involves setting and assessing performance targets at various levels (vehicle, system, and component) to ensure that all design objectives and specifications are met.