Driving Innovation with Tailored Testing Solutions for Every Industry

At DEP, we offer cutting-edge testing solutions for a wide range of multidisciplinary applications. Our expertise encompasses the development and optimization of modern vehicle systems and engines, ensuring safety and adaptability as we advance toward the future of mobility.

Our services span from straightforward test procedures to intricate projects, all tailored to meet your specific requirements. We pride ourselves on delivering exceptional quality at every stage of the process.

Services

- Dynamo meter Testing

- Load Testing

- Vibration and Shock Testing

- Electro magnetic Compatible

- Material Testing

- Customized Bench Testing

- Virtual Testing

- In-Loop Testing

- Unit Testing

- Functional Testing

- Acceptance Testing

- Automation Testing

Dynamometer Testing

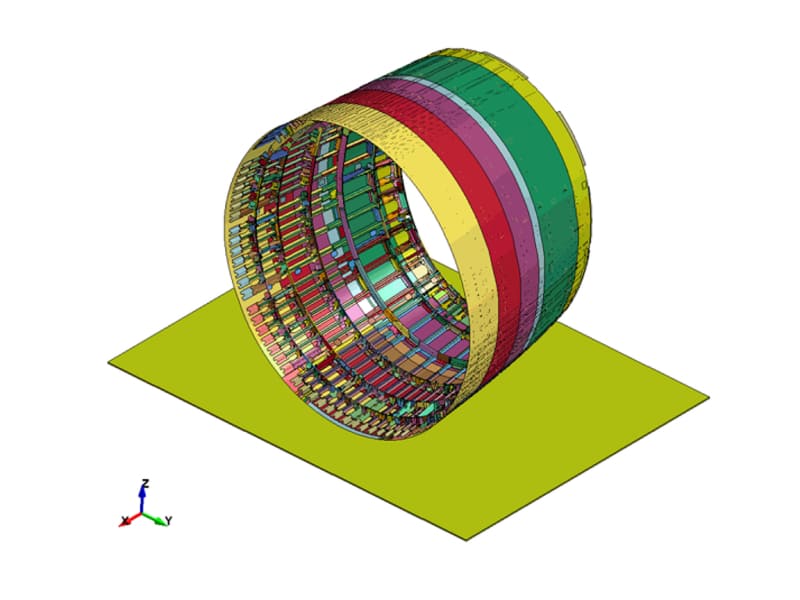

Dynamometer testing is a critical service for assessing the performance and efficiency of vehicle powertrains. This testing provides precise measurements of power output, torque, and rotational speed, ensuring that vehicles meet performance standards and regulatory requirements.

DEP Capabilities:

Engine and chassis dynamometer testing.

Real-time data acquisition and analysis.

Simulation of different driving conditions and loads.

Integration with advanced diagnostic tools.

Load Testing

Load testing is essential for evaluating the structural integrity and performance of vehicle components under various conditions. This testing simulates real-world stresses to ensure the durability and reliability of the vehicle.

DEP Capabilities:

Static and dynamic load testing.

Fatigue testing for long-term durability assessment.

Advanced instrumentation for precise measurement and analysis.

Customizable testing protocols to meet specific requirements

Penetration Testing

Functional Safety Testing

SOTIF Tests

Vibration and Shock Testing

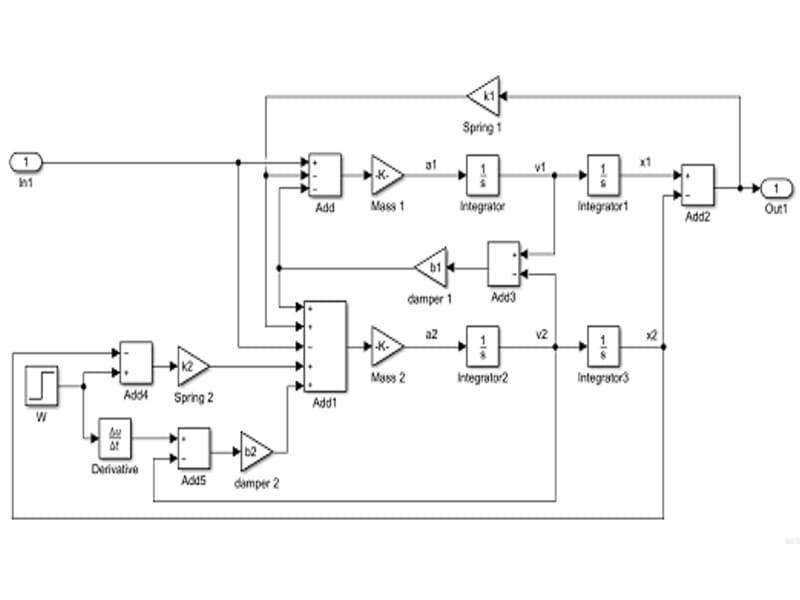

Vibration and shock testing assess the vehicle’s ability to withstand the impacts and vibrations encountered during normal operation.

DEP Capabilities:

Simulation of Road Conditions

Resonant searches and dwells

Fixture resonance evaluation

Combined vibration and environmental

Electrodynamic (ED) shakers can be used for Accelerated Stress Testing (AST)

Strain monitoring during vibration

Data Acquisition and Analysis

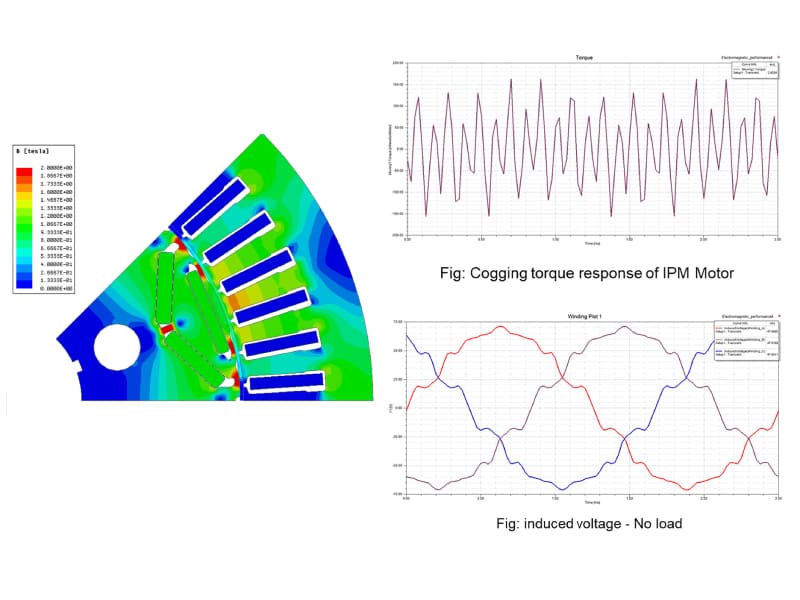

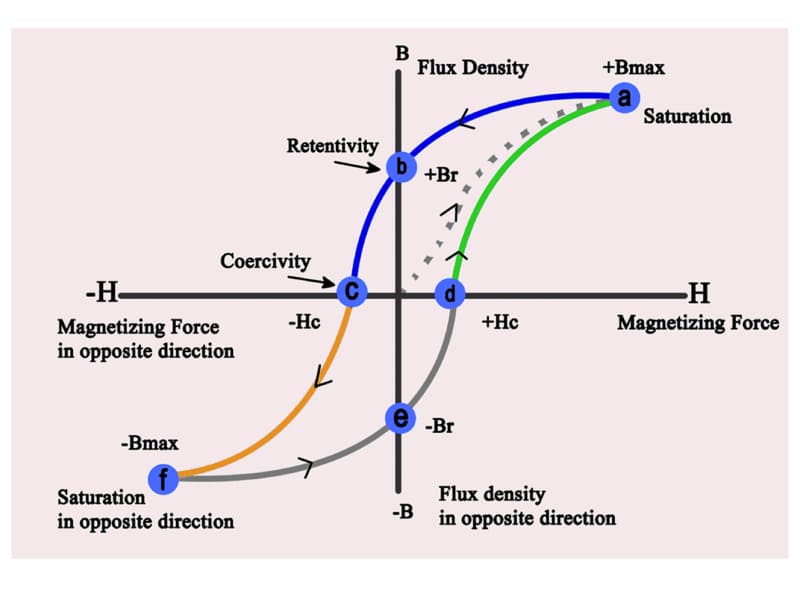

Electromagnetic Compatibility (EMC) Testing

EMC testing ensures that the vehicle's electronic systems operate reliably without electromagnetic interference.

DEP Capabilities:

Radiated Emission Testing

Electrostatic Discharge (ESD)

Power Quality Testing

Surge Testing

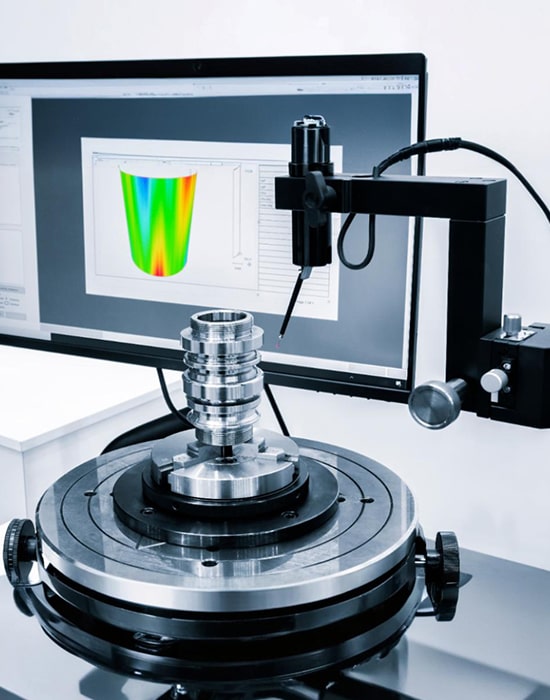

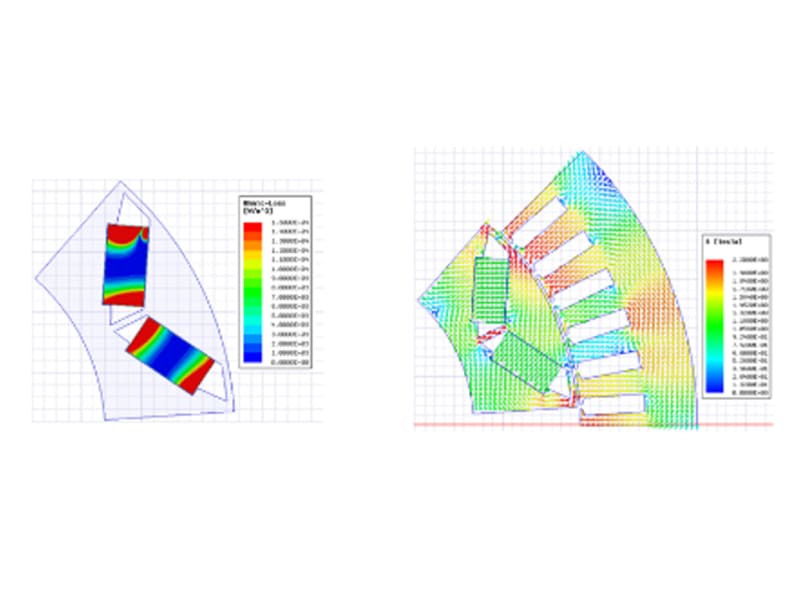

Material Testing

Material testing in a vehicle involves evaluating the mechanical properties, durability, and safety of materials used in its construction. This process ensures components can withstand operational stresses, environmental conditions, and impact forces. It includes tests for strength, fatigue, corrosion, and thermal resistance. Reliable material testing is crucial for vehicle performance, safety, and longevity.

DEP Capabilities:

Tensile Testing

Fatigue Testing

Creep and Stress Rupture Testing on metallic materials

Chemical Analysis

Hardness Testing

Customized Bench Testing

DEP’s Customized Benchtesting involves tailoring performance tests to match the specific requirements and conditions of a system or application. This approach ensures that tests accurately reflect real-world scenarios and system constraints, providing more relevant and actionable insights. By focusing on unique use cases and configurations, customized benchtesting helps optimize performance and reliability for diverse operational environments.

DEP Capabilities:

Engine hydraulic device

Solenoid Force Test Rig

Flow Measurements

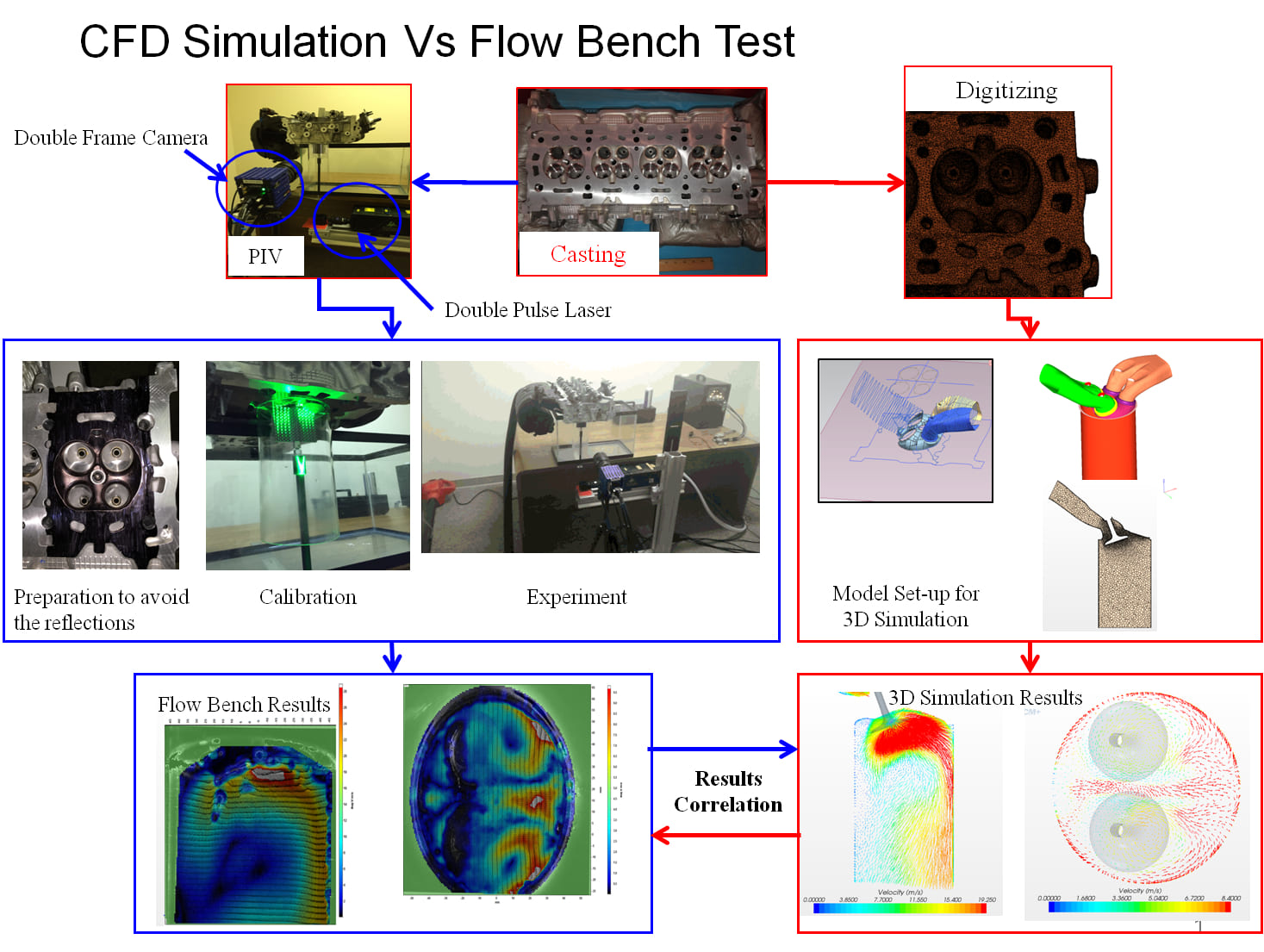

Virtual Testing

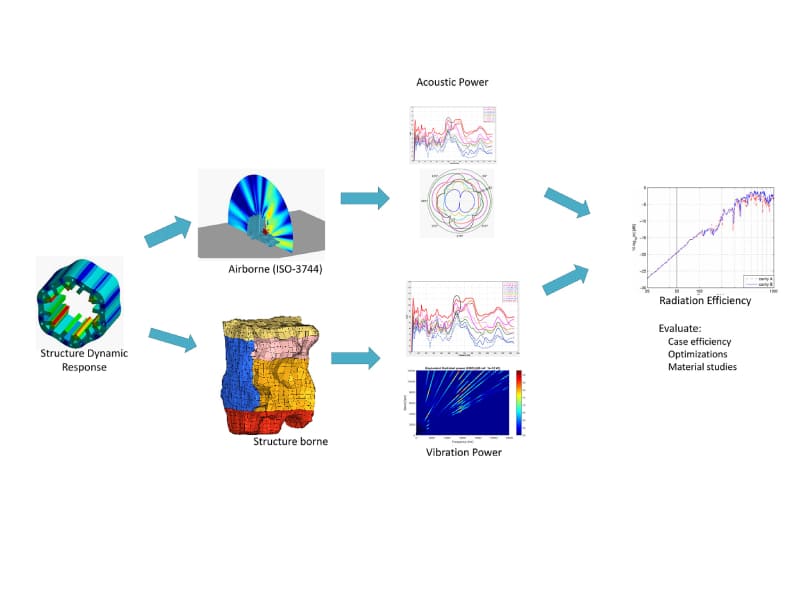

Virtual testing provides a digital platform to simulate and evaluate vehicle performance, safety, and durability. This service enhances design accuracy and accelerates development by allowing extensive testing without physical prototypes.

DEP Capabilities:

Fully Automated Testing Frameworks for Function and Algorithm Validation

Virtual HIL – SILVER for Powertrain and Transmission Control Unit

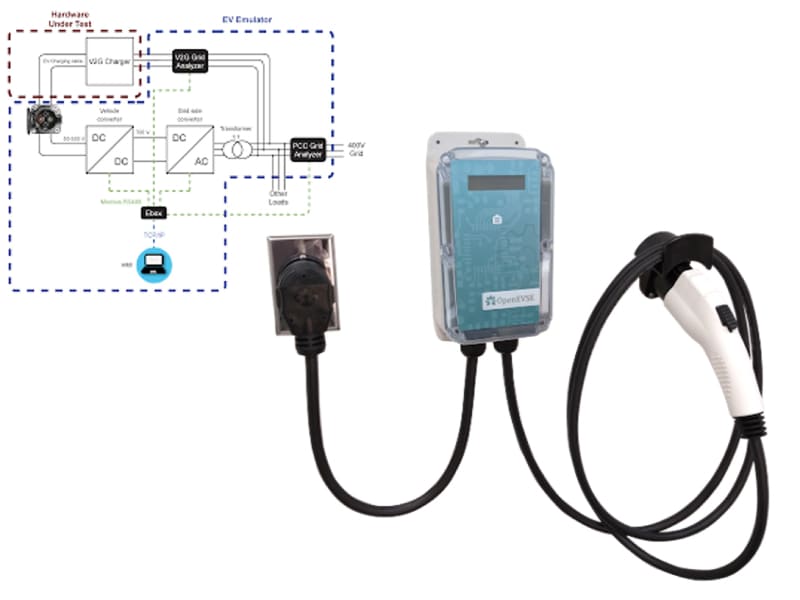

Low-Cost Device Emulators for EOL Testing – Charging Equipment, Control Units

Scripts for Testing APIs, Dashboard Functionality

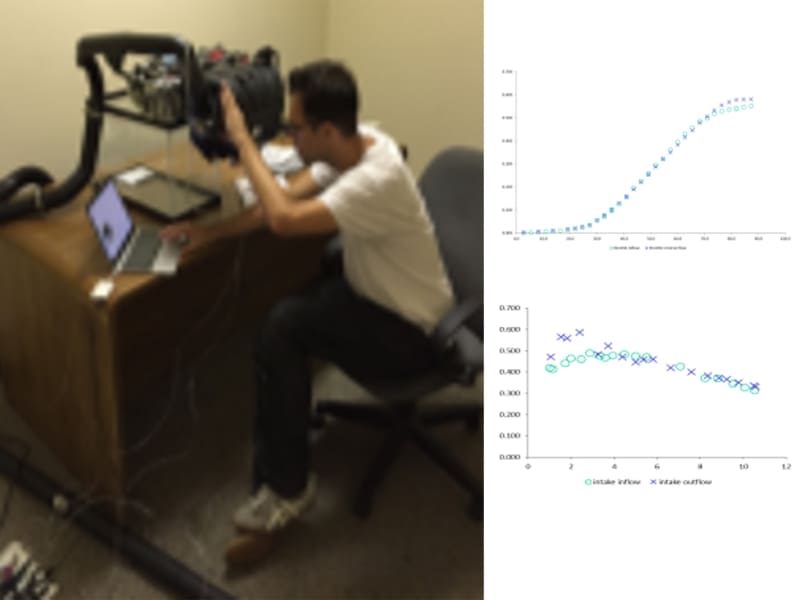

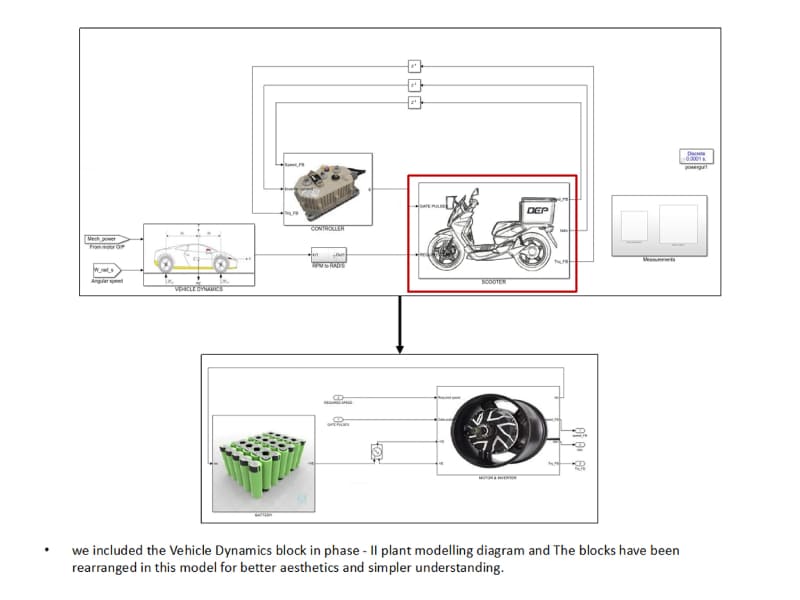

In-Loop Testing

In-Loop Testing integrates real-time simulations with vehicle control systems to validate performance and functionality. This method ensures that software and hardware interact correctly under various conditions, allowing for precise adjustments and improvements. By bridging the gap between simulation and real-world operation, In-Loop Testing enhances reliability and reduces development time.

DEP Capabilities:

Model In Loop Testing within Tool or Between Tools

FMU & S-Functions for In Loop Testing

Rapid Control Prototyping using Micro Autobox, NI Veristand, Opal-RT hardwares

Code Generation and Target Hardware Evaluation

Control Unit calibration with Vector CANAPE, ETAS Inca

Hardware in Loop Testing with Opal-RT real time HIL

Test bench integrations for Motor, Controller, Battery and Vehicle

Vehicle in Loop Testing with CarSim, SimulationX

Driver In Loop Testing for ADAS Function Development

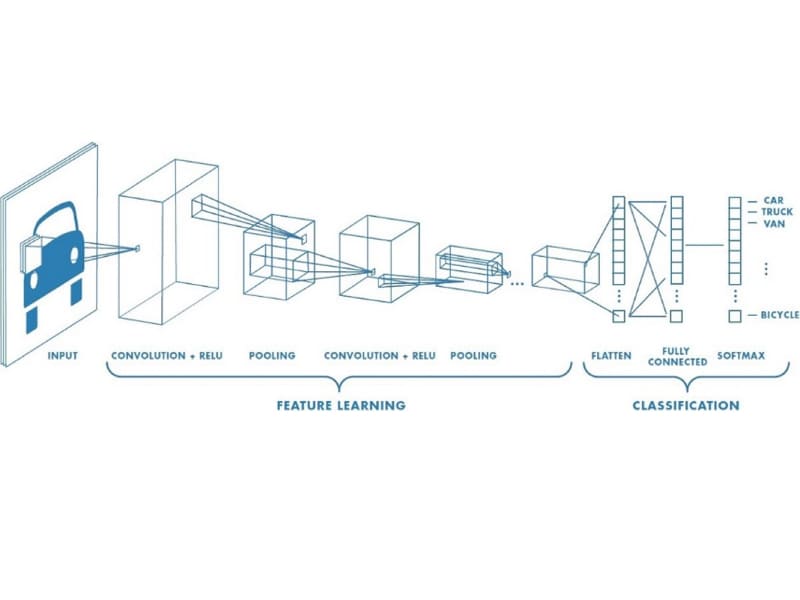

Unit Testing

Unit Testing focuses on verifying individual components or modules of vehicle software to ensure they function correctly in isolation. This process helps identify and resolve issues early in development, improving overall system reliability and performance. By isolating each unit, engineers can ensure robust and error-free integration into the larger vehicle system.

DEP Capabilities:

Unit Testing strategies as per ISO 26262 Part 6.9

Methods, Test Cases, and Coverage as per Table 10 of ISO 26262

Branch Coverage & Modified Condition / Decision Coverage MCDC

Functional Testing

Functional Testing assesses whether vehicle systems and features operate according to specified requirements. This testing evaluates the functionality of various components, such as infotainment, safety systems, and drive controls, ensuring they perform as intended in real-world scenarios. It helps identify issues and ensures that all functions meet quality and performance standards.

DEP Capabilities:

Test systems for diagnostics

Test systems for residual bus simulation

Test automation

Custom Built Test Rigs for Automated Testing

Instrument Clusters, ECU, BCM, ADAS ECU, EPS etc.,

Acceptance Testing

Acceptance testing ensures that a vehicle or component meets all defined specifications and performance criteria before it is approved for release. This testing phase verifies that the product is compliant with safety regulations and quality standards, often involving simulated and real-world scenarios to validate its readiness for market.

DEP Capabilities:

Acceptance Testing – UAT / OAT / FAT

Manual & Automated Testing Frameworks

AUTOSAR acceptance tests ICC1

Automation Testing

Automation testing involves using specialized tools to verify and validate the functionality of vehicle systems and software. Automation helps accelerate the development process, ensures compliance with safety standards, and improves the overall quality and safety of automotive technologies.

DEP Capabilities:

Automation Scripts for In Loop Testing

Automation Frameworks for Function / Algorithm Testing

Python, M-Script, QT

DEP Value Addition

Customized testing for automotive, aerospace, electronics, and medical industries.

Real-world condition simulation and virtual testing to identify design issues early.

Integration of advanced tools for dynamic load, vibration, and EMC testing.

In-depth material testing for strength, fatigue, and corrosion resistance.

Automation and scripting for efficient, high accuracy testing and validation.

Application Domains

Why Us?

DEP provides tailored testing solutions with advanced simulation and engineering expertise, ensuring high-quality, reliable results across industries. Our approach accelerates time-to-market while meeting rigorous standards for product integrity and safety.

Comprehensive Testing Solutions

Our testing services cover a wide range of industries, from automotive and aerospace to consumer electronics. We offer specialized solutions tailored to each sector’s unique needs, ensuring accurate and reliable results across diverse applications.

Advanced Simulation Capabilities

Leveraging state-of-the-art simulation technologies, we provide in-depth analyses that replicate real-world conditions. Our simulation-driven approach helps in identifying potential issues early in the design phase, reducing development time and costs while enhancing product performance.

Cutting-Edge Engineering Expertise

Our team of highly skilled engineers brings extensive experience in testing and validation. We employ the latest engineering methodologies and tools to deliver precise and actionable insights, ensuring that your products meet the highest standards of quality and safety.

Rigorous Testing Standards

Adhering to industry standards and regulations, we conduct thorough testing processes to validate the integrity and durability.

Customized Testing Solutions

Our flexible testing services are designed to accommodate specific requirements and challenges. Whether it’s for prototyping, production, or quality assurance, we tailor our testing approach to meet your precise needs.

Accelerated Time-to-Market

By combining advanced simulation with efficient testing procedures, we help you streamline the development process and accelerate your time-to-market. Our proactive approach ensures that potential issues are addressed early, allowing you to launch faster and stay ahead of the competition.