Design Optimization

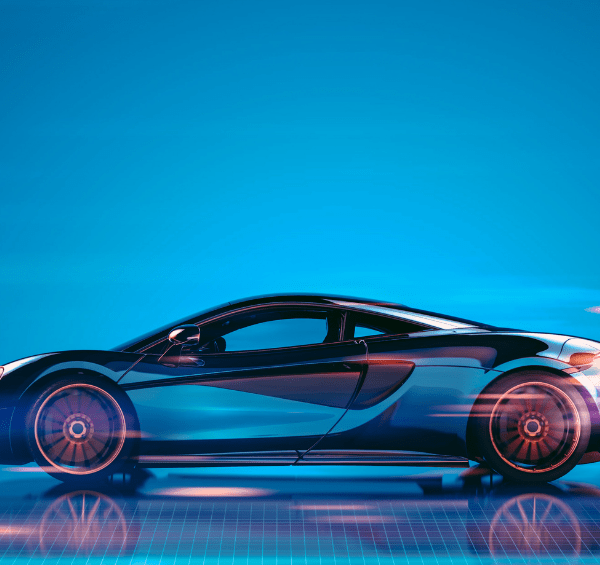

Comprehensive Design Optimization Solutions for Enhanced Engineering Efficiency Across Industries

Optimizing Design for better efficiency, performance, and cost.

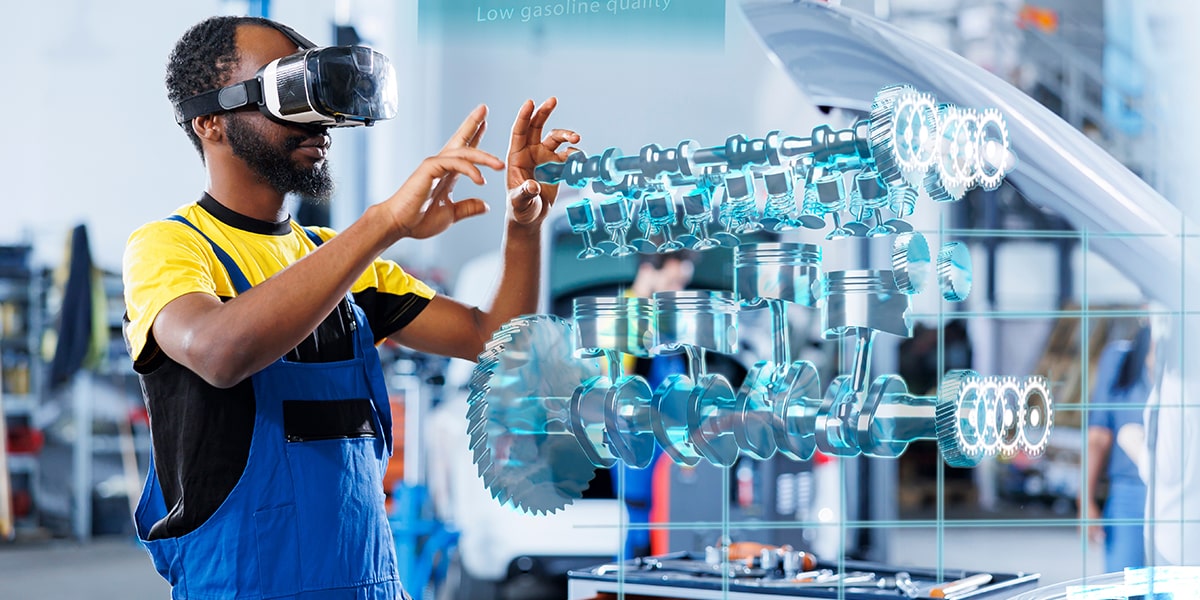

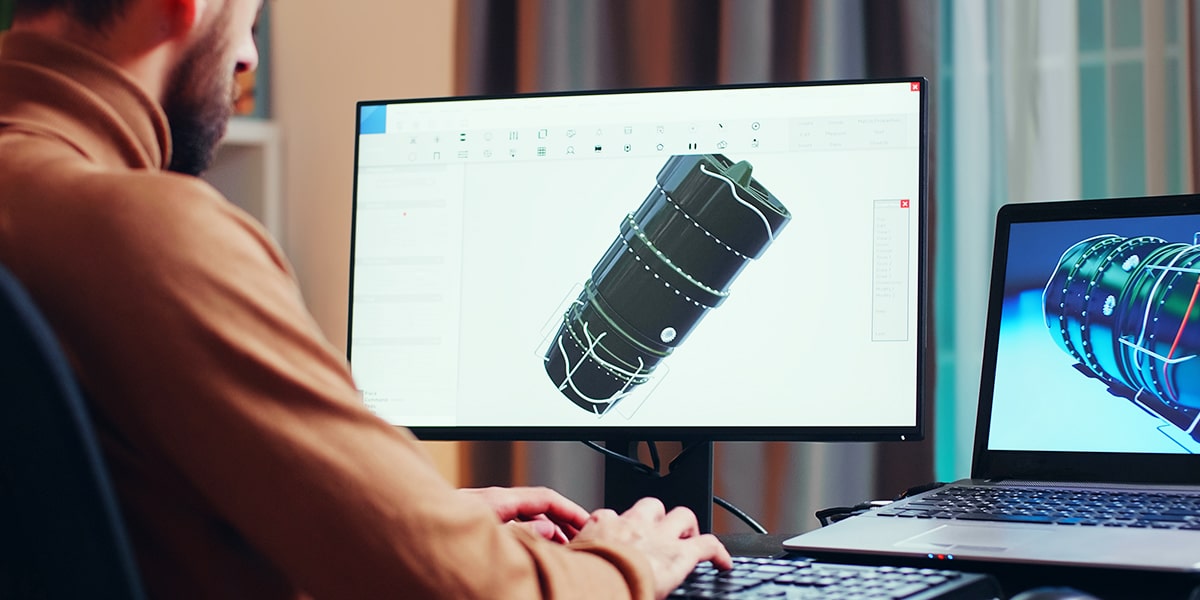

The goal of optimization is to find the “optimal” design based on a set of prioritized criteria or constraints. These include aspects such as increasing production, strength, dependability, durability, efficiency, and usage. The analysis stage of the engineering design process is when mathematical models and scientific principles are employed to help the designer predict design results. Engineers are often forced to identify a few appropriate design solutions and then decide which one best meets the needs of the client.

DEP identifies optimization scenarios that have numerousobjectives and are multivariate in nature as it works across industrial verticals. The changing needs and DEP’s in-house Engineering procedures have resulted in optimization approaches and tools that manage a wide range of situations, and our solutions are suitable for various stages of product development.

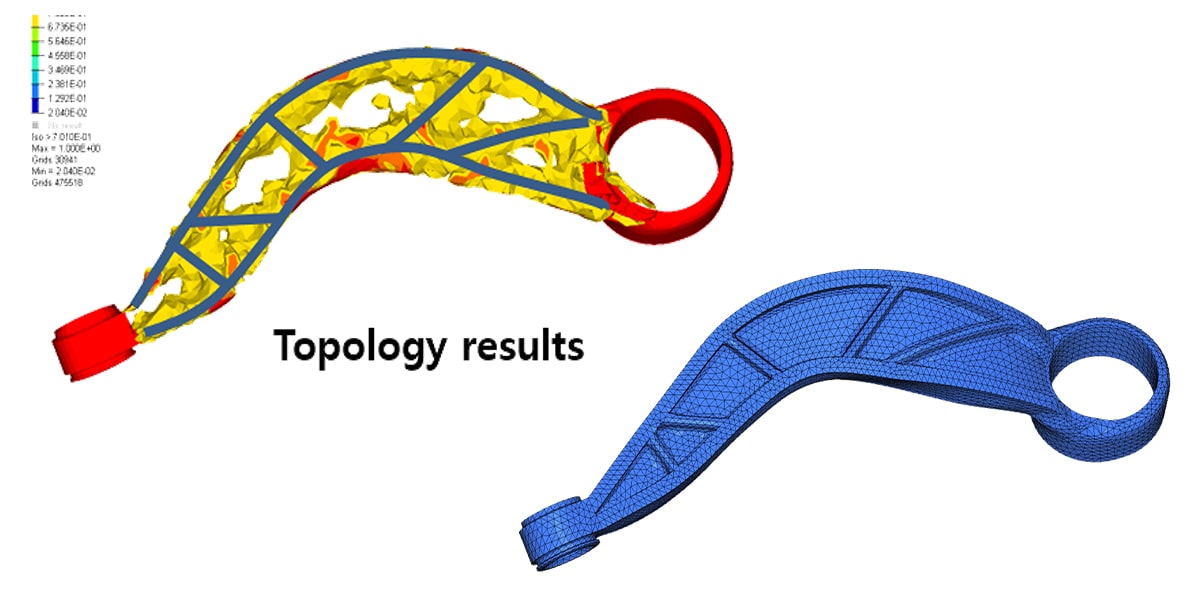

Topology Optimization

Our topology optimization capabilities focus on determining the most efficient material distribution within a given design space. This helps engineers create lightweight structures with optimal performance, ensuring that material usage is minimized while maintaining strength and functionality.

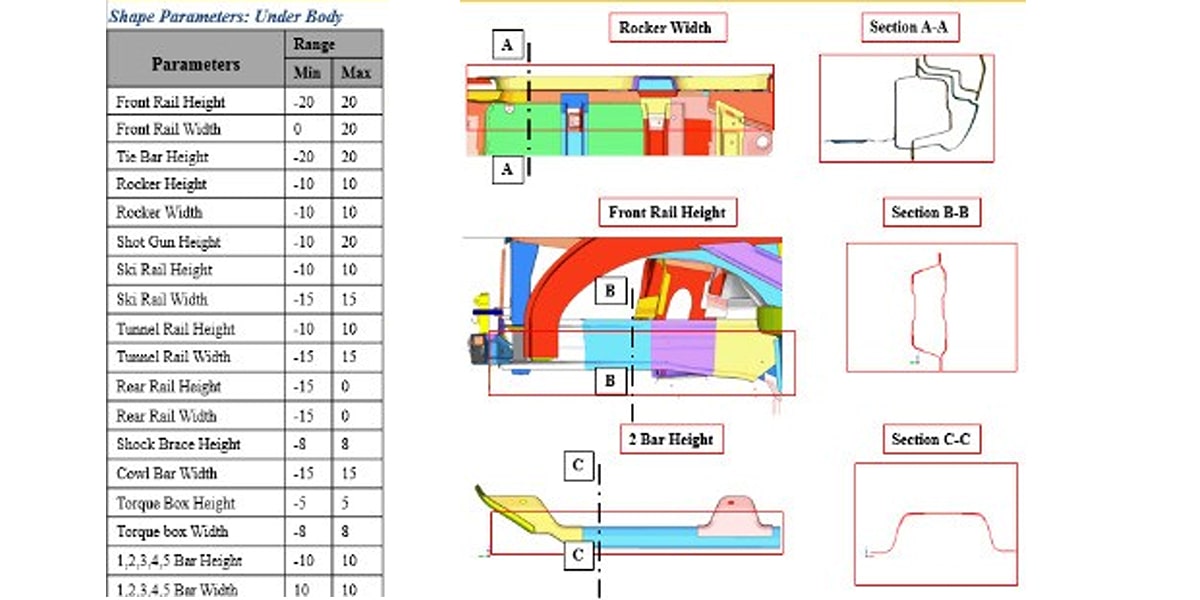

Shape, Structure & Parametric

Optimization

We offer shape, structure, and parametric optimization to enhance product performance. By refining the geometry and structure of components, we ensure better load distribution, improved durability, and overall design efficiency, while allowing for flexibility in adjusting design parameters.

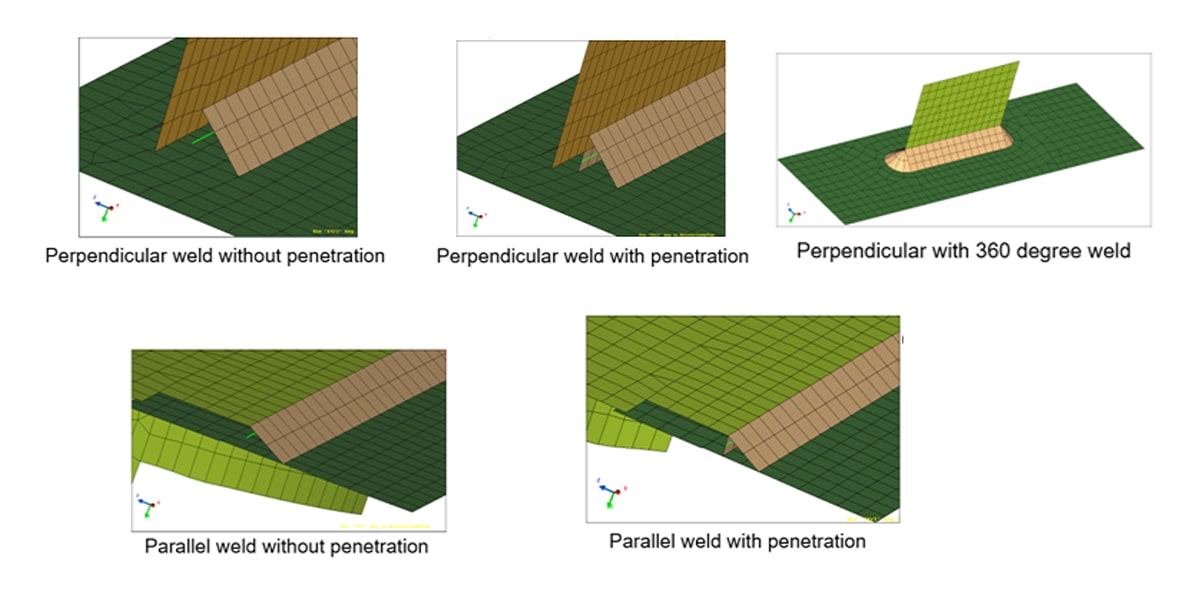

Weld Optimization

Our weld optimization techniques improve the strength, durability, and efficiency of welded structures. Through simulation and analysis, we determine optimal weld paths, sizes, and materials, reducing stress concentrations and ensuring long-lasting, reliable joints.

Section Optimization

DEP's section optimization focuses on refining cross-sectional shapes and sizes to achieve the best balance between strength, weight, and cost. This approach helps enhance structural integrity while minimizing material usage, ensuring both performance and cost-effectiveness.

Weight Optimization

We specialize in weight optimization to reduce excess material without compromising strength or safety. By leveraging advanced algorithms and simulations, we achieve lighter, more efficient designs that enhance performance, reduce fuel consumption, and improve overall sustainability.

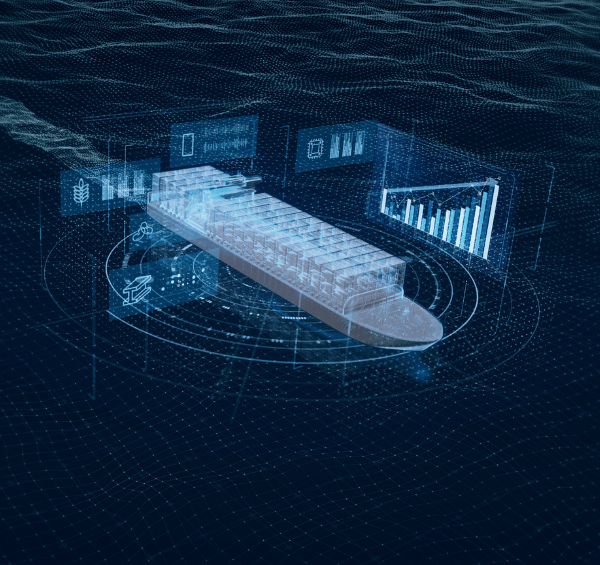

MDO (Multidisciplinary Design

Optimization)

Our MDO approach integrates multiple design disciplines to achieve optimal solutions. By considering factors such as performance, cost, and manufacturability, we ensure that all aspects of a product are optimized simultaneously, leading to more efficient and effective designs.

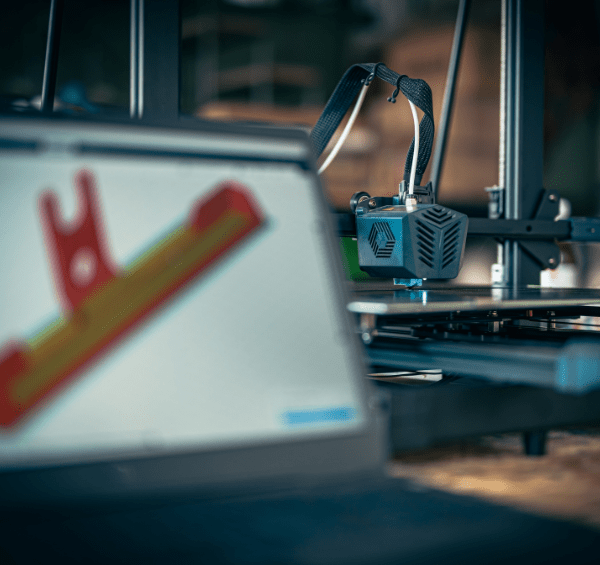

Topology Optimization:

Lightweight and performance-driven structural design

Efficient material distribution within the design space

Multi-objective optimization (stiffness, strength, vibration, thermal, cost)

Design tailored to real-world loads and boundary conditions

Topology optimization compatible with additive manufacturing

Seamless integration with CAD/CAE workflows

Stress, fatigue, and durability considerations for reliability

Rapid iteration and concept validation of multiple designs

Shape, Structure & Parametric Optimization:

Shape optimization to enhance performance, aerodynamics and reduce stress concentrations

Structural optimization for maximum stiffness, strength, and durability with minimal weight

Parametric optimization to systematically evaluate design variations

Multi-objective optimization balancing performance, cost, weight, vibration, and thermal criteria

Seamless integration with CAE/CAD workflows for analysis and manufacturing

Fatigue and durability assessment for long-term reliability

Combination of topology and shape optimization for advanced designs

Rapid iteration and concept validation of multiple design alternatives

Support for multi-disciplinary optimization (MDO) integrating structural, thermal, and dynamic requirements

Weld Optimization:

Weld design optimization for improved strength, durability, and reduced material usage

Stress and load analysis of weld joints under operational conditions

Fatigue and durability assessment for cyclic loading

Thermal and distortion analysis of heat-affected zones

Optimization of welding techniques, sequences, and process parameters

Seamless integration with CAD/CAE workflows

Multi-objective optimization balancing strength, weight, cost, and manufacturability

Rapid evaluation of multiple weld configurations

Ensures compliance with structural, safety, and fabrication standards

Section Optimization:

Optimize cross-sectional geometry for maximum strength-to-weight ratio

Analyze stress and load distribution to minimize high-stress regions

Reduce material usage while maintaining structural integrity

Multi-objective optimization balancing weight, stiffness, strength, and cost

Conduct parametric studies to evaluate multiple section designs

Seamless integration with CAD/CAE workflows for manufacturing readiness

Assess fatigue and durability for long-term reliability

Rapid iteration and validation of section design alternatives

Weight optimization:

Reduce component and system weight while maintaining performance and safety

Optimize material selection and distribution for efficiency

Balance weight reduction with strength, stiffness, cost, and manufacturability

Ensure lightweight designs meet load, fatigue, and durability requirements

Explore multiple design alternatives through parametric and topology studies

Seamless integration with CAD/CAE workflows for analysis and production

Rapid iteration and validation of weight reduction strategies

Maintain thermal and dynamic performance under operational conditions

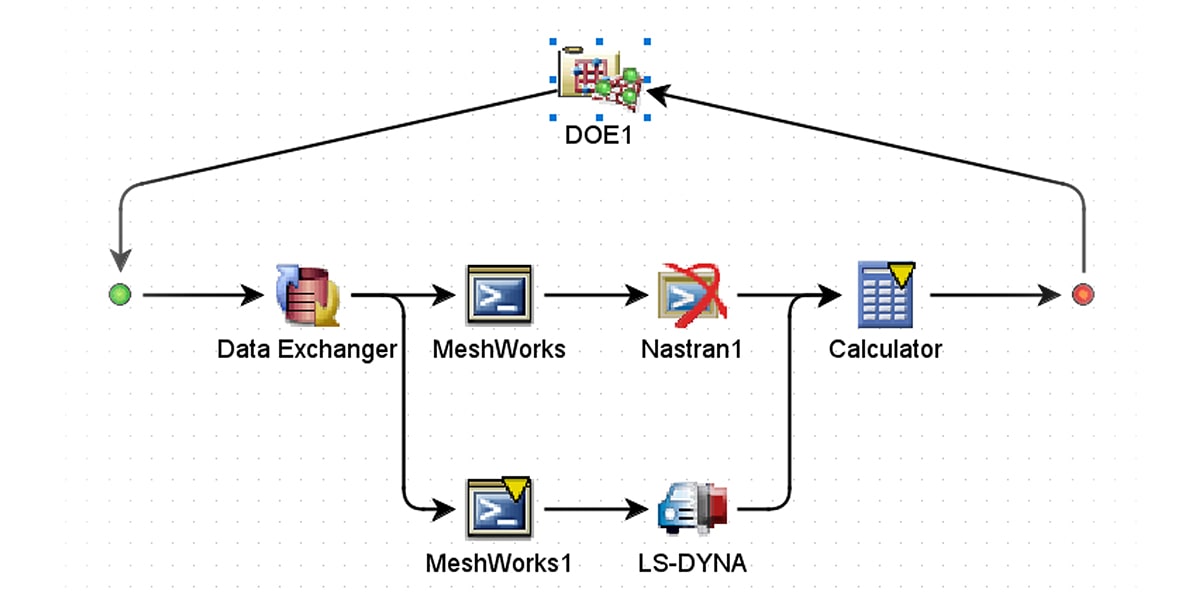

Multi-Disciplinary Optimization:

Simultaneously optimize multiple disciplines (structural, thermal, aerodynamic, NVH)

Balance competing objectives like weight, cost, strength, stiffness, and efficiency

Conduct parametric and sensitivity studies to identify key design parameters

Rapidly iterate and validate multiple design alternatives

Integrate MDO results seamlessly into CAD/CAE workflows for manufacturing

Explore design space to find optimal trade-offs and feasible solutions

Ensure reliability and durability under operational and safety requirements

Combine MDO with topology, shape, and section optimization for advanced solutions

Support system-level decision-making and holistic design improvements

DEP Advantages

We provide exceptional CAE Services and our commitment to provide industry leading Design Optimization to the global clientele has continued to strengthen our reputation making us the chosen partner for engineering service in the market. We promise you the advantage of:

Quality Service

Expert Support

Custom Tailored Solutions

Advanced Technology

Timely Delivery

Competitive Rate