Industrial Equipments

Advanced Industrial Equipment Solutions

Engineering the Future of Industrial Equipment Solutions

DEP offers comprehensive engineering services tailored to industrial equipment solutions. Our expertise spans design and development, where they create and optimize equipment to meet precise performance standards. They utilize advanced simulation tools for in-depth analysis, ensuring durability and efficiency. DEP also provides prototyping services to validate designs before full-scale production and supports the transition from design to manufacturing.

Our Services

Production Machinery

DEP’s solutions for production machinery focus on increasing automation, precision, and efficiency. We provide end-to-end support from concept design to final prototyping, leveraging advanced CAE and digital twin technologies. Our services enable the optimization of machinery for various industries, ensuring smoother operations, minimal downtime, and enhanced performance.

DEP Key Capabilities

Digital Twin

Computer-Aided Design (CAD)

Industrial Products

Our engineering and simulation capabilities for industrial products help clients develop highly durable and reliable components across a wide range of applications. DEP focuses on enhancing design quality, improving material utilization, and reducing manufacturing costs. From electrical components to heavy machinery parts, we ensure each product meets stringent industry standards.

DEP Key Capabilities

Topology Optimization

Material Simulation

Heavy Equipment

DEP offers comprehensive solutions for heavy equipment, focusing on improving strength, efficiency, and operational life. Our multidisciplinary approach integrates advanced simulation, predictive analytics, and design services to optimize heavy-duty machines for industries such as mining, construction, and material handling. We ensure that the equipment is built for high performance under extreme conditions.

DEP Key Capabilities

Predictive Analytics

Fatigue & Durability Analysis

Manufacturing Equipment Services

DEP specializes in providing innovative solutions for designing, developing, and optimizing manufacturing equipment. Our services focus on enhancing efficiency, durability, and process reliability.

DEP Key Capabilities

Design & Simulation

Prototyping & Validation

Durability Analysis

Digital Manufacturing

Process Optimization

Automation Equipment Services

DEP delivers cutting-edge automation solutions to streamline production processes, integrate smart systems, and reduce operational downtime. Our expertise ensures seamless and intelligent automation implementation.

DEP Key Capabilities

Control Systems Integration

Smart Manufacturing

Predictive Maintenance

IoT & Industry 4.0

Capabilities

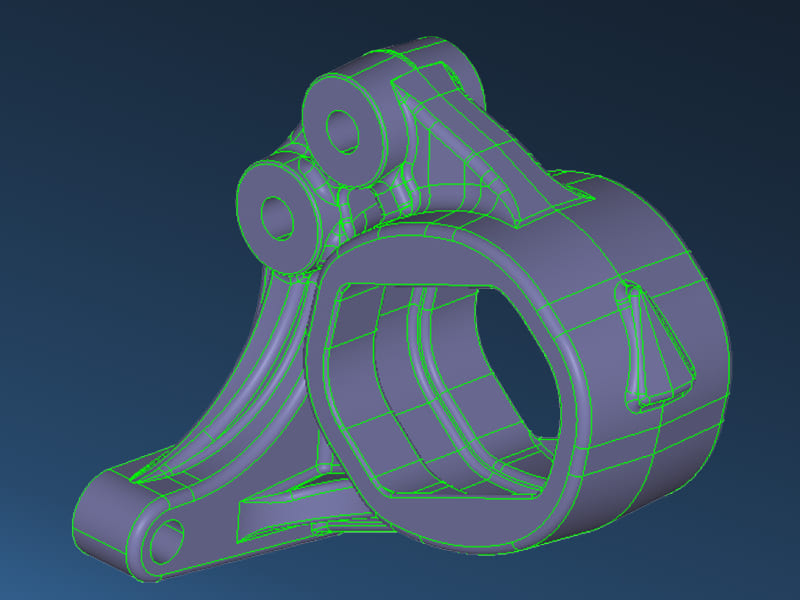

CAD Modeling

DEP provides comprehensive CAD modeling services, creating detailed digital models of machinery and components using advanced CAD software. These models enable precise visualization, performance simulation, and design optimization before physical prototypes are Sconstructed.

VAVE (Value Analysis/Value Engineering)

DEP's VAVE services focus on improving the value of products by systematically analyzing their functions and identifying cost-effective alternatives. The goal is to enhance performance or reduce costs while maintaining essential functionality.

Strength and Durability

DEP provides robust strength and durability analysis to ensure that equipment can withstand operational stresses and environmental conditions over time. This service includes stress analysis, material selection, and lifecycle predictions to prevent failures and extend the lifespan of products.

Dynamics and NVH

DEP offers specialized analysis services in dynamics and NVH, focusing on mitigating the effects of noise, vibration, and harshness in machinery. This service enhances product comfort and compliance by reducing unwanted noise, managing vibrations, and ensuring smooth operation.

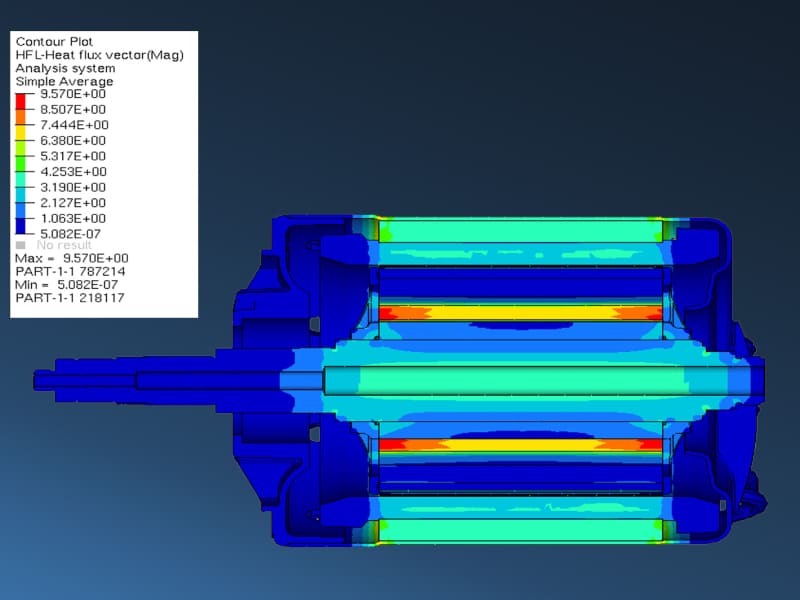

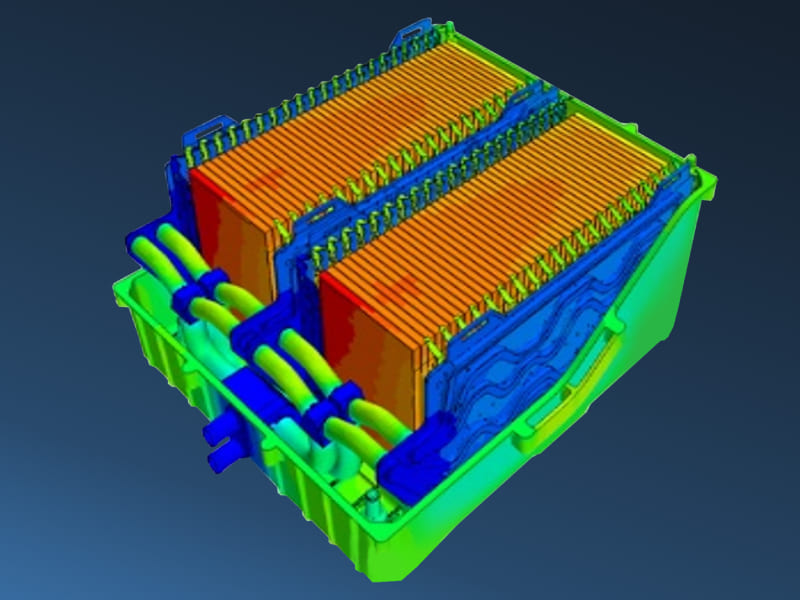

Thermal Management

DEP’s thermal management services are designed to control the temperature of equipment, ensuring efficient and reliable operation. This includes designing cooling systems, implementing temperature controls, and selecting appropriate materials to manage heat effectively.

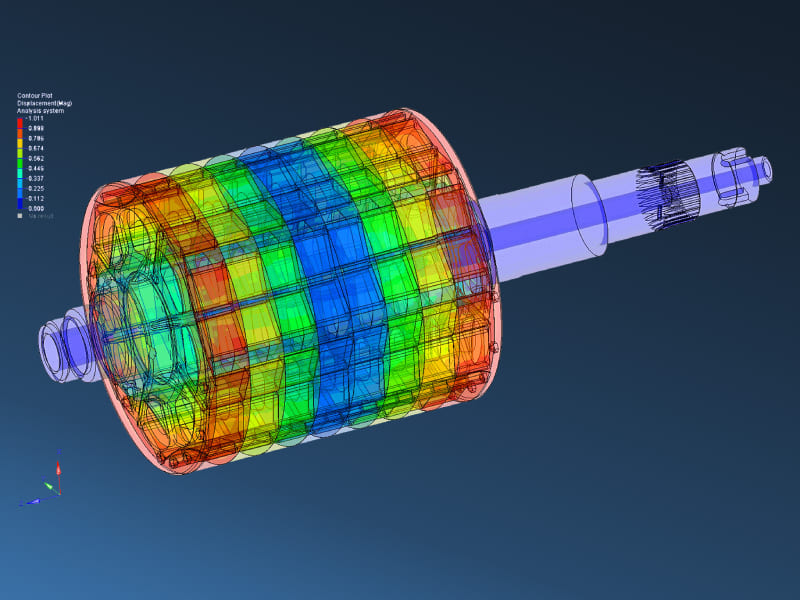

Rotor Dynamics

DEP provides comprehensive rotor dynamics services, focusing on the behavior of rotating components such as shafts and rotors. This includes ensuring proper balancing, managing critical speeds to prevent resonances, and designing bearings to handle rotational forces and minimize vibrations.

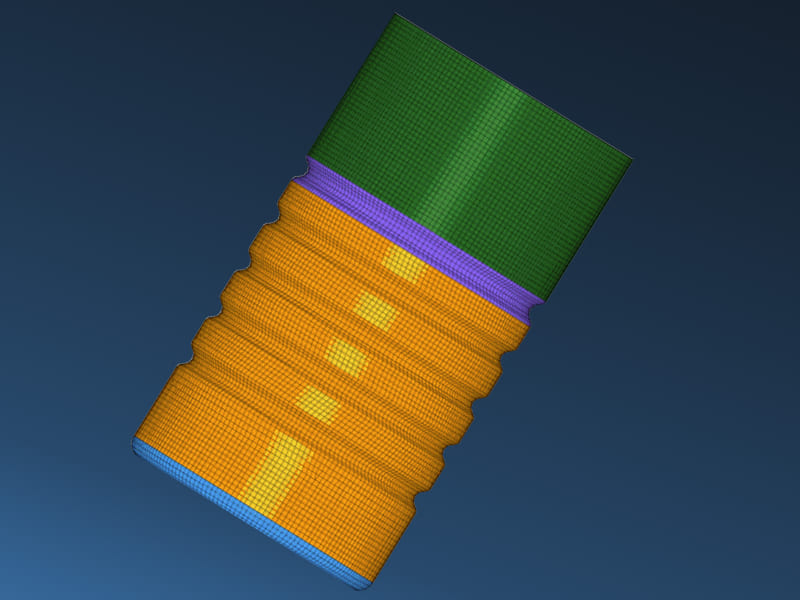

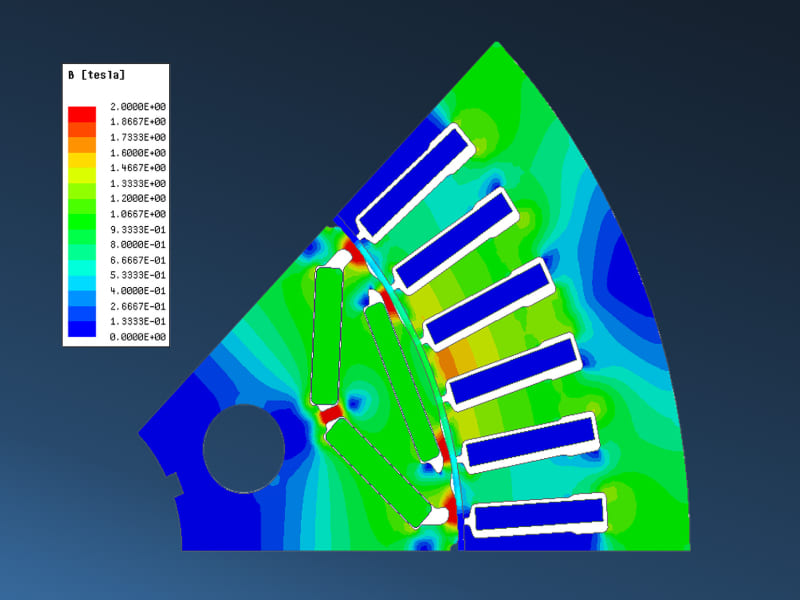

Simulation

Predict, validate and optimize the industrial equipment designs with analyses — including mechanical (FEA), computational fluid dynamics (CFD), plastic injection Moulding, composite materials, and manufacturing simulations.

Benefits Of Scalable Industrial Equipment Solutions