What Does Reduced Order Modelling (ROM) Do?

MeshWorks’ advanced Reduced Order Modelling (ROM) functionality transforms traditionally complex modelling tasks into a streamlined, automated workflow. With just a few guided steps, users can generate parameterized ROMs that accurately link geometric sections to corresponding beam properties. This automation accelerates simulation processes, enabling faster analysis and improved design iterations.

Accelerated CAE Workflows

MeshWorks ROM reduces solver time by up to 50%, significantly enhancing simulation throughput and shortening design cycles.

Efficient Parametric Optimization

Parameterized ROMs enable quicker optimization studies, reducing solution time and boosting productivity in CAE workflows.

Design-to-Manufacture Integration

ROM models facilitate the optimization of cross-sections and geometry, aligning structural performance with manufacturing constraints.

Automated Topology Identification

The system automatically detects joints and tubular regions to support targeted ROM creation, minimizing manual intervention.

Take a quick tour of ROM

Features of ROM

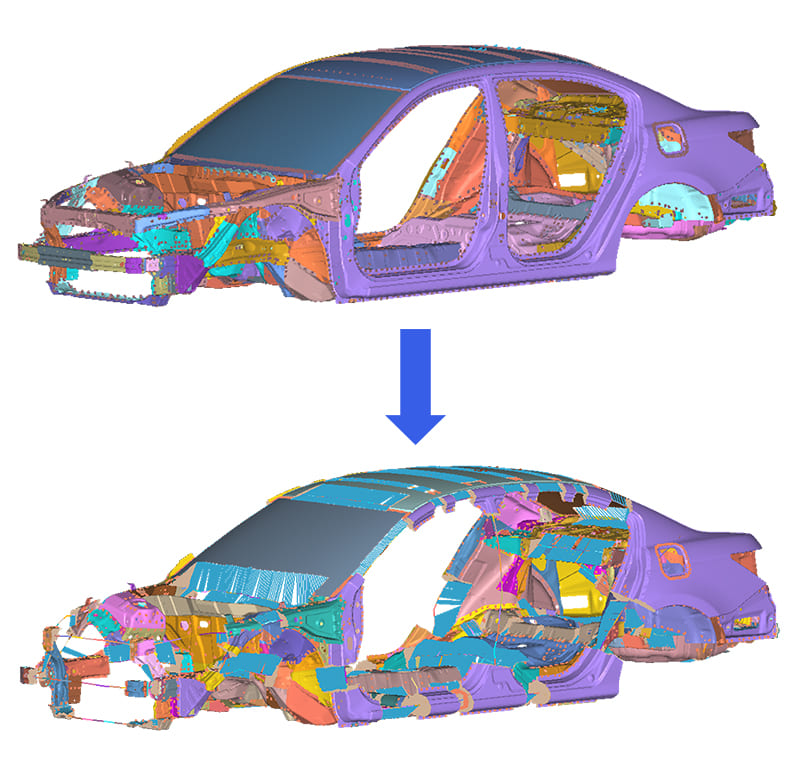

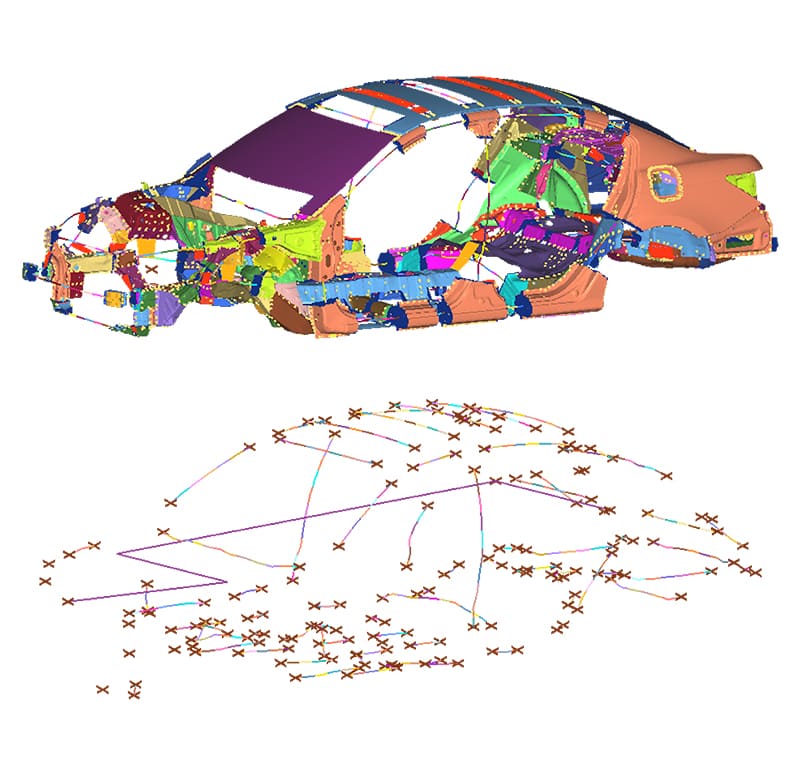

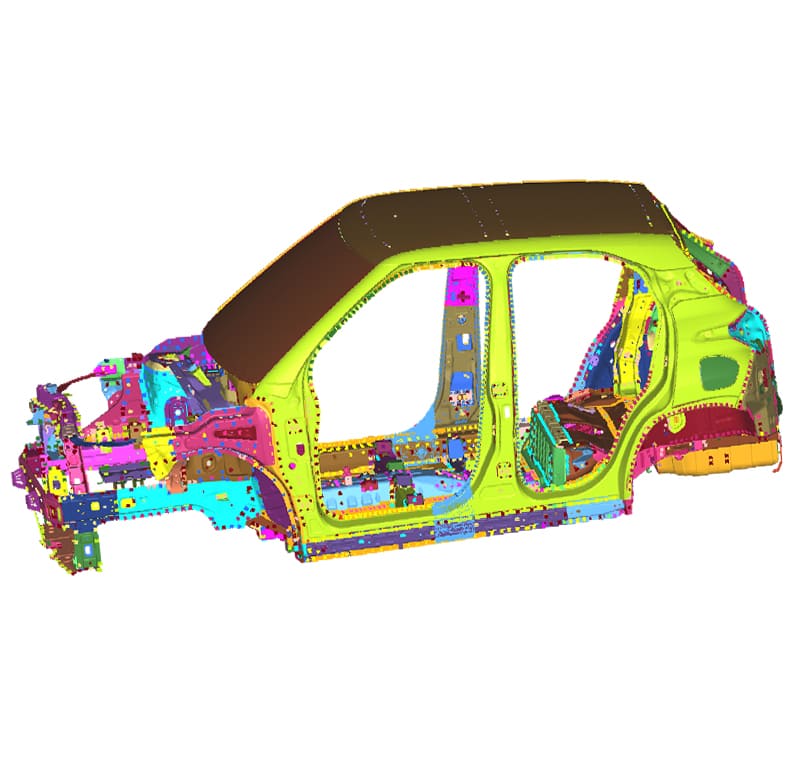

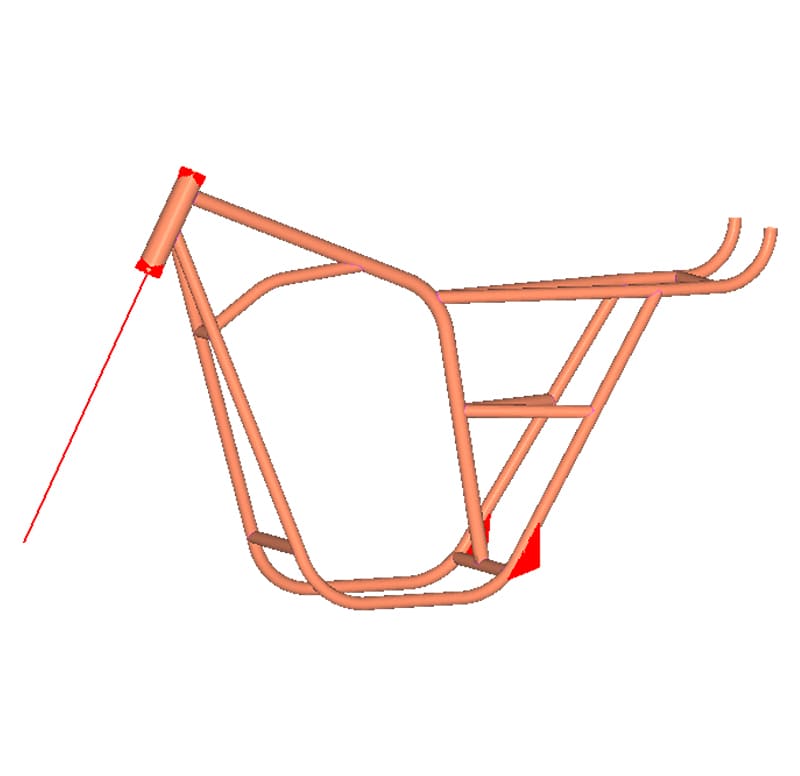

3D to 1D Conversion

Efficiently converts complex 2D/3D structures into simplified yet high-fidelity 1D beam models.

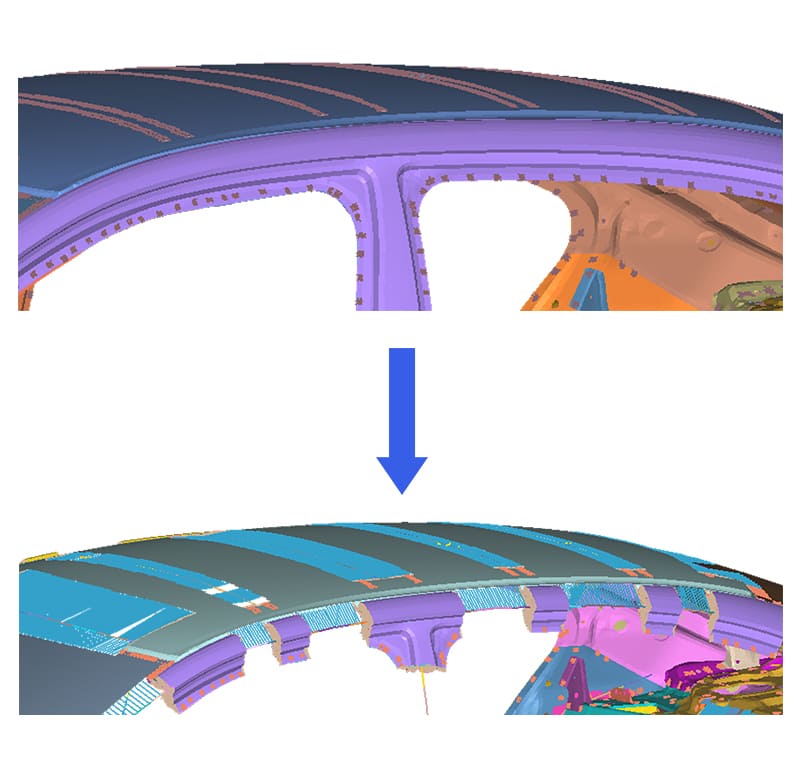

Topology & Cross-Section Detection

Automatically identifies structural joints and members to accelerate cross-sectional modelling and simplification.

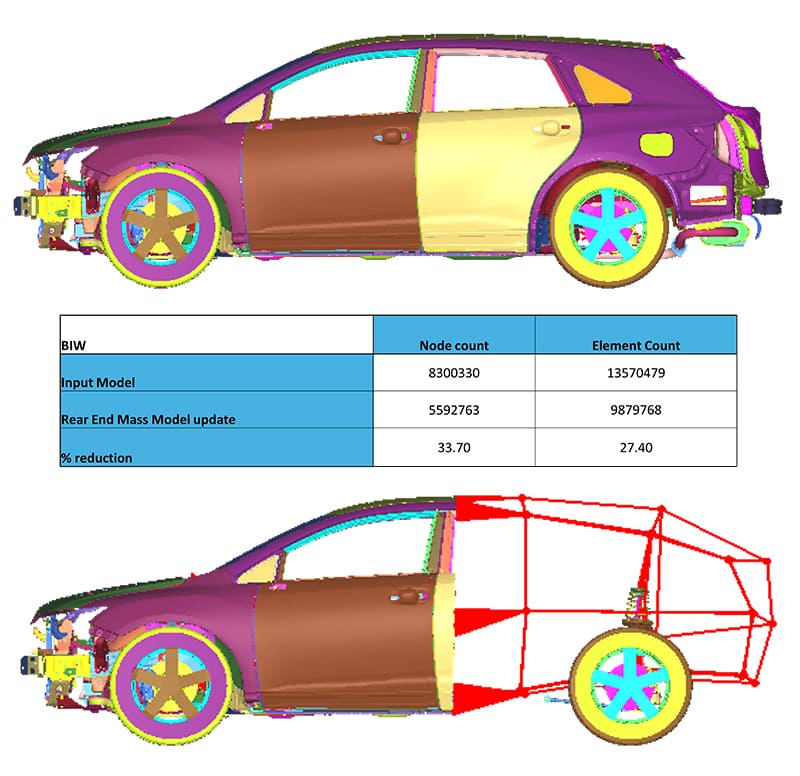

Solver Time Optimization

Fewer nodes and elements enable faster solver execution and reduced computational overhead.

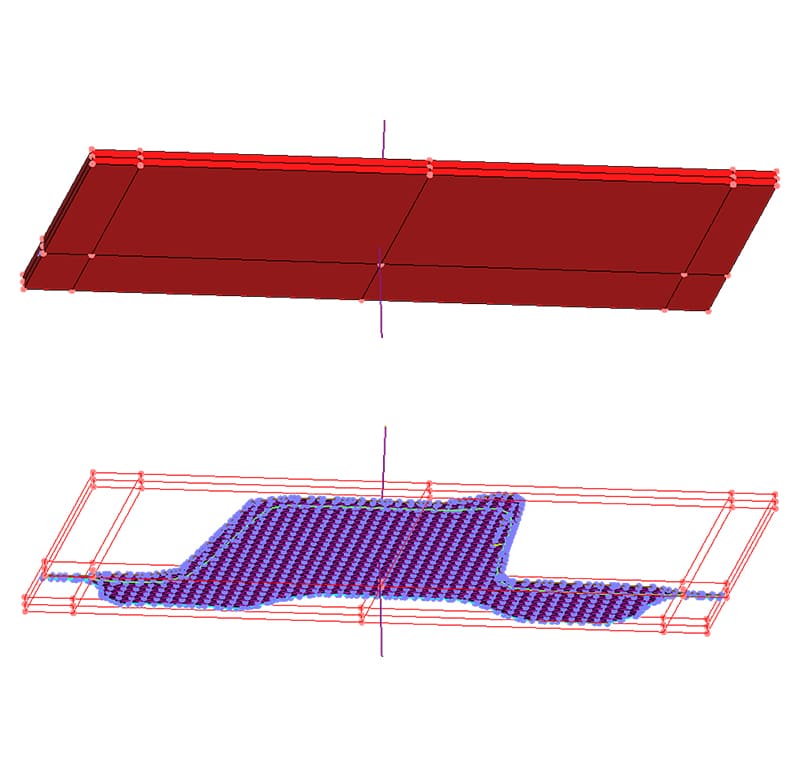

Cross-Section Parameterization

Supports dynamic adjustment of beam properties—height, width, and other geometric features—for rapid design variations.

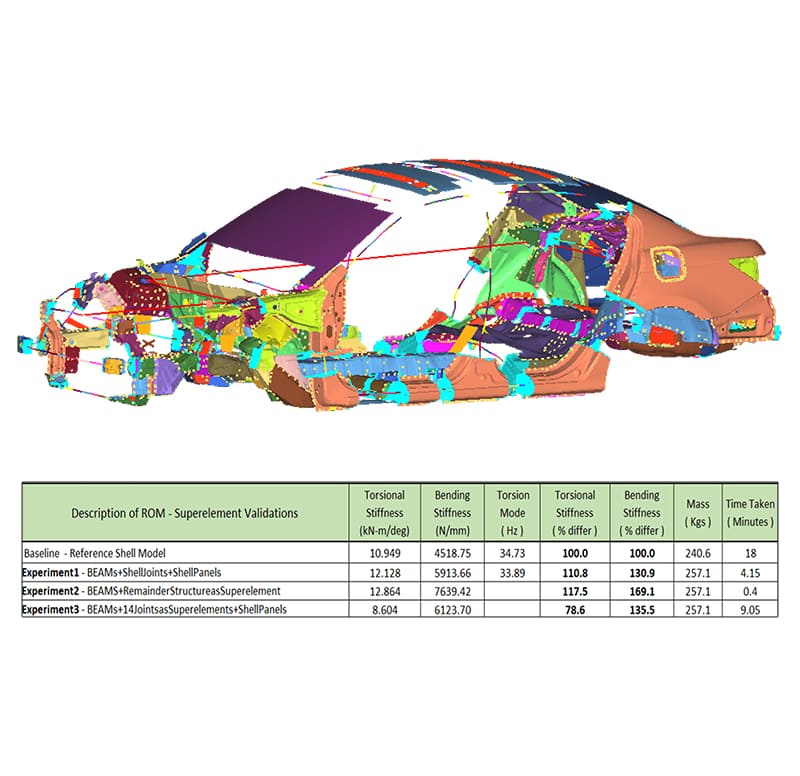

Super Element Modelling

Converts intricate joint models into reduced super-elements while maintaining accurate structural response.

High Model Correlation

ROMs generated in MeshWorks closely replicate full-order model behavior, ensuring predictive reliability.

Automated ROM Creation

Generates reduced-order models from detailed FE data with minimal manual effort, increasing modelling efficiency.

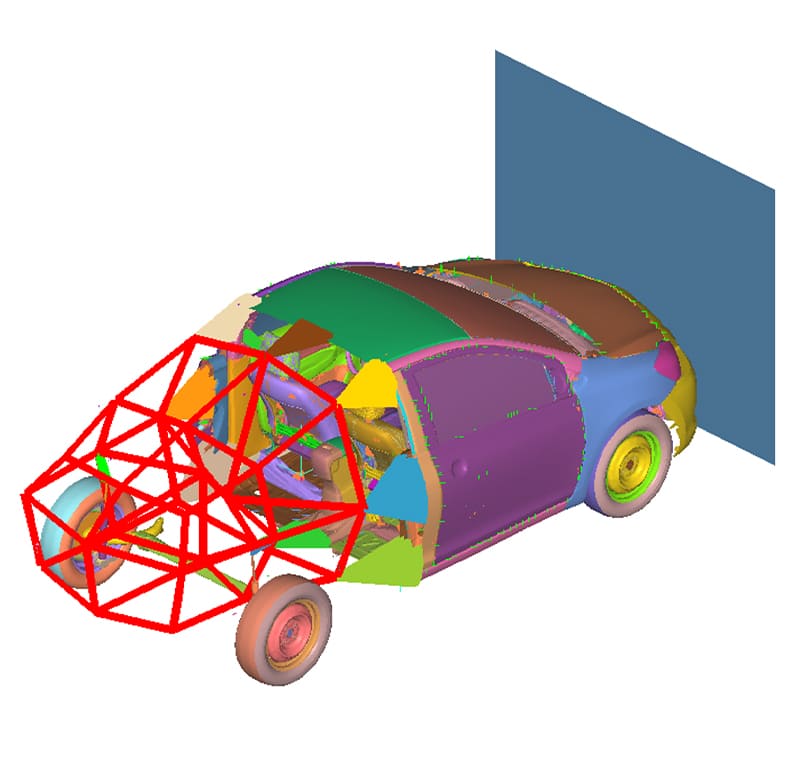

Discipline-Specific Tools

Customizable ROM capabilities for domains such as Crash, NVH, and Durability ensure application-specific accuracy.

Geometry-to-Property Integration

Automatically maps geometric attributes to physical properties, streamlining parametric studies.

Get a Closer Look at

Get all the details about our CAE platform’s capabilities, technical specifications, and success stories.

MeshWorks Uniqueness

The ROM module in MeshWorks intelligently condenses detailed finite element (FE) models into lightweight, high-accuracy parametric 1D representations. It simplifies complex 3D structural assemblies into equivalent 1D beam models without compromising behavioral fidelity. This enables faster simulations across domains such as crash and NVH, significantly reducing solver time while retaining accurate predictive capabilities.

Faster CAE Turnaround

Achieve up to 50% reduction in solver time, accelerating both analysis and product development cycles.

Automated Parametric Modelling

Direct integration between geometry and beam properties enables rapid design modifications and efficient parametric studies.

Application-Specific Fidelity

Leverage specialized ROM tools tailored to crash, NVH, and structural domains, ensuring optimized accuracy and performance.

Lightweight Model Conversion

Streamline large, complex assemblies into simplified beam models, preserving essential behavior for fast and effective analysis.

Technical Brief

Deep dive into the technical strengths of MeshWorks ROM functions with comprehensive detailing using explanatory videos

Resources

Explore our library of resources to learn more

Ready To Transform Your

Product Development?

Join leading manufacturers who use MeshWorks to accelerate innovation, reduce development costs, and bring better products to the market faster.