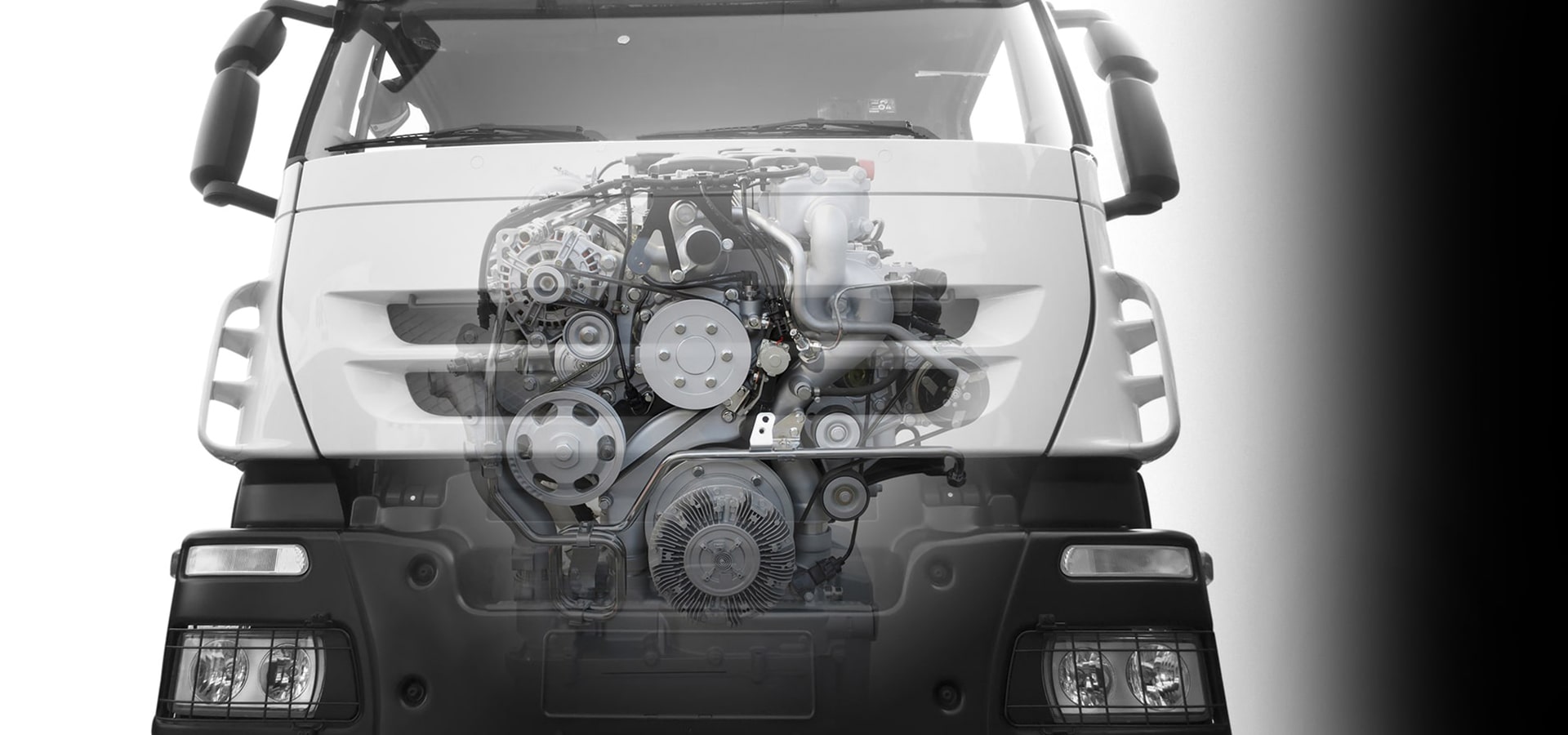

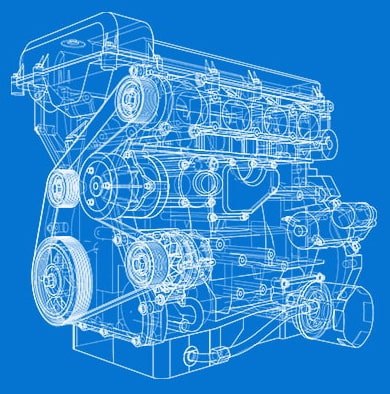

High Efficiency Engine

High-Efficiency Engine Engineering Solutions

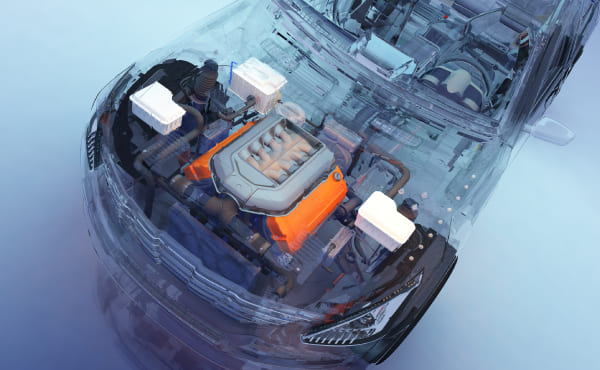

DEP provides specialized engineering services aimed at enhancing the efficiency and performance of modern engines. Our simulation methodology ensures precise optimization of the PCV system by matching ventilation flow with blow-by generation, enabling improved system efficiency while maintaining engine performance and drivability. With deep expertise in advanced powertrain development, DEP leverages a Model-Based Systems Engineering approach to deliver high-fidelity CAE solutions. Our capabilities span performance evaluation, thermal management, fuel economy analysis, lubrication and after-treatment system studies, and detailed competitor benchmarking—supporting OEMs in building cleaner, smarter, and more efficient engine platforms.

DEP’s Commitment to Innovation in High Efficiency Engine Technology

At Detroit Engineered Products (DEP), we continuously refine our methods to

Our superior engineering solutions and services position us as a key player in the

Webinar

Industry Applications of DEP High Efficiency Engine Technology

Key Distinguishers

DEP’s Engine Technology

DEP’s engines combine exceptional fuel efficiency with reduced emissions, ensuring high performance without sacrificing power. By integrating hybrid technologies, turbocharging, and precision components, each engine is customized to meet the specific needs of sectors like automotive, aerospace, and heavy machinery. DEP also emphasizes durability and reliability in diverse operating environments, making these engines ideal for high-demand applications, ultimately lowering long-term operational costs and reducing environmental impact.

Full Engine Development Approach

DEP’s production engine development strategy is built on a customized systems engineering methodology that ensures high performance, maximum carry-over capacity, cost efficiency, and reduced time-to-market. To meet the growing demand for greener and more efficient engines, we integrate advanced features such as torsional vibration reduction, friction and noise minimization, combustion optimization, after-treatment systems, and hybridization technologies, enabling peak performance and sustainability.

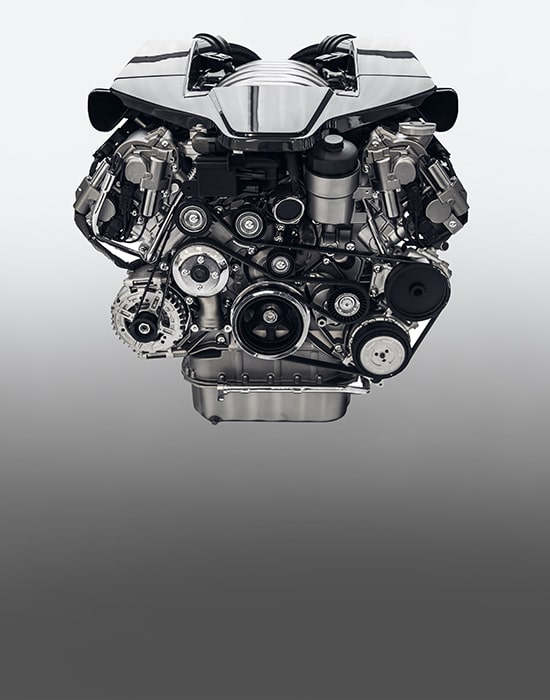

Cutting-Edge Tools and Technologies

DEP MeshWorks, our proprietary CAE platform, which reduces FE and CFD model-building time by 50-80%.

Accelerates rapid concept model generation, parameterization, optimization, and CAD morphing while enabling multi-disciplinary optimization and quick design iterations. By focusing on durability, NVH, cooling, lubrication, and combustion chamber optimization, our approach achieves up to a 40% improvement in vehicle-level fuel economy.

Tools like CAD-morpher technology and intelligent design enablers further streamline processes, bridging the gap between design and engineering for innovative solutions.

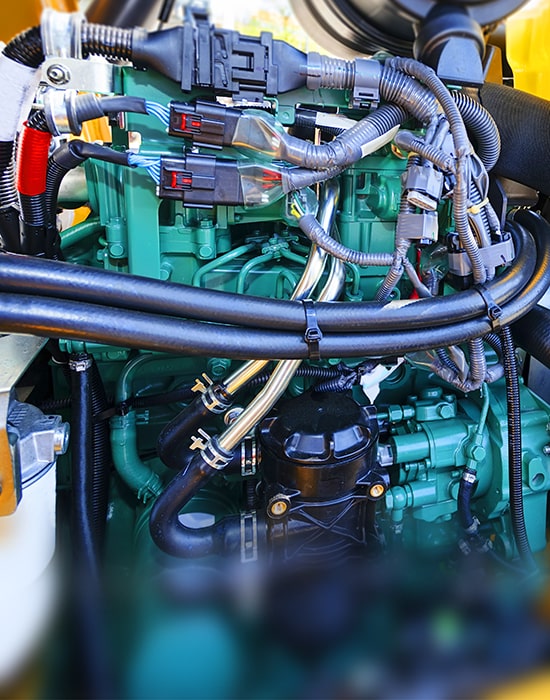

DEP’s High Efficiency Engine Development Capabilities

Engine design & development

Packaging

Manufacturability

Ventilation Performance

Cooling Performance

Lubrication Performance

Part & Combustion Chamber Optimization

Cranktrain Dynamics

Intake Manifold optimization

Engine Performance

Powertrain NVH

Combustion strategy

Fuel injection Strategy.

Increased CR

Combustion chamber design

Fuel selection

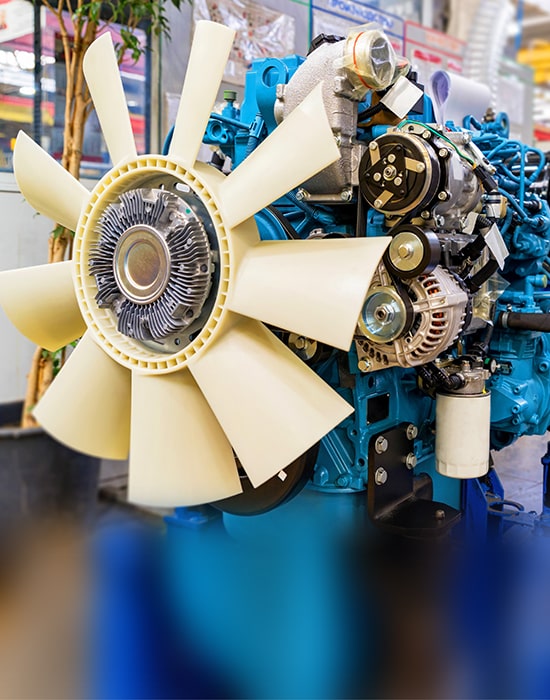

DEP Advantages

An highly efficient engine should require performance optimization, components optimization, mass efficiency strategy, engine testing, and general CAE functionalities like thermodynamics, systems modeling, combustion, heat/thermal management, induction/intake, block-head durability, crank-train dynamics, engine/powertrain NVH, ventilation, lubrication, etc. With our expert services, we provide a complete suite of services that aim to increase the quality of engines that are being developed.

Customer Benefits

Significant Emission reduction

Mechanical Effectiveness

Efficiency of Thermodynamics

Fuel Conversion Optimization