Multibody Dynamics (MBD)

Empowering Engineering Excellence with Advanced Multibody Dynamics

Precision and Performance with DEP’sMBD Solutions

Multibody Dynamics (MBD) plays a pivotal role in engineering and simulation, offering critical insights into the motion, forces, and interactions of interconnected systems. MBD allows engineers to understand and optimize dynamic behaviors, ensuring precision and performance. It bridges the gap between theoretical designs and real-world applications, reducing costly physical prototypes and accelerating development cycles.MBD simulations enable engineers to analyze complex assemblies under various operating conditions, predict failures, and refine designs. Its applications span a wide range of industries, supporting advancements in vehicle dynamics, robotics, biomechanics, and more. By integrating MBD into the design process, companies can minimize risks, improve safety, and achieve compliance with industry standards while cutting down on time-to-market.

At Detroit Engineered Products (DEP), we offer cutting-edge MBD solutions to address the dynamic challenges of modern engineering. Leveraging advanced simulation tools and expertise, our team delivers accurate and efficient multibody dynamics analysis tailored to client needs. With DEP’s proprietary MeshWorks, we enhance MBD workflows through automated processes, rapid model creation, and parameterization, enabling quick iterations and design optimization. Whether it is automotive, aerospace, or commercial vehicles, DEP's solutions ensure your products meet the highest standards of reliability, safety, and performance.

Mechanical Systems Analysis

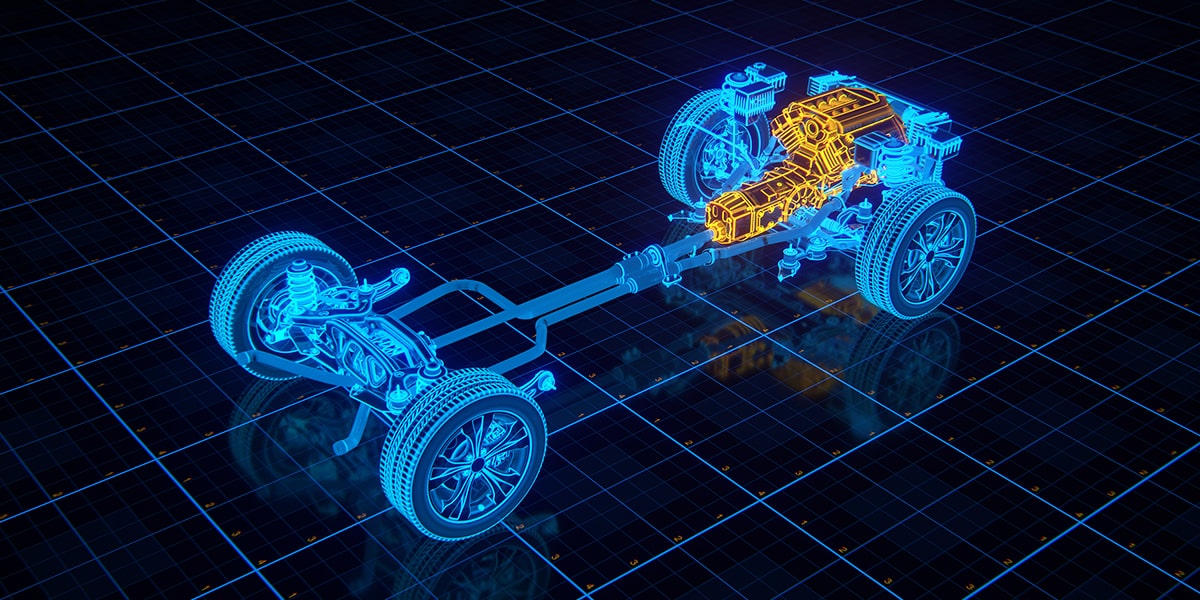

Our multi-body dynamics expertise allows for the comprehensive evaluation of mechanical systems, analyzing their motion, forces, and interactions under real-world conditions. We ensure accurate simulation of complex assemblies, optimizing performance, durability, and efficiency for diverse engineering applications.

Sub-System/Component Level

Analysis

We focus on detailed analysis at the sub-system and component level, examining individual parts for their dynamic behavior and integration within larger systems. This approach helps identify potential improvements, ensures seamless functionality, and enhances overall product performance.

Mechanical Systems Analysis

Study motion, velocity, acceleration, and forces in mechanical systems

Analyze both rigid structures and flexible components under operational loads

Evaluate natural frequencies, mode shapes, and dynamic response

Assess forces, moments, and stress distribution in mechanical assemblies

Predict system behavior for complex mechanisms and linkages

Analyze interactions between moving parts for wear and performance

Evaluate system performance under both time-dependent and steady conditions

Seamless transition from design to analysis and optimization in CAD/CAE workflows

Improve system performance, reliability, and efficiency through optimization and parametric studies

Sub-System/Component Level Analysis

Detailed analysis of individual components and sub-systems for performance evaluation

Structural, thermal, and dynamic analysis at sub-system and component level

Stress, fatigue, and durability assessment under operational conditions

Vibration, modal, and harmonic analysis for component reliability

Fluid flow and thermal interaction studies for critical sub-systems

Optimization of design parameters for improved efficiency and performance

Contact, friction, and wear analysis for moving components

Integration with CAD/CAE workflows for seamless design-to-analysis process

Rapid iteration and validation of multiple component design alternatives

DEP Advantages

We deliver outstanding CAE services and are dedicated to offering industry-leading Model-Based Design (MBD) solutions to our global clients. Our commitment has solidified our reputation as the preferred partner for engineering services. By choosing us, you gain the advantage of:

Quality Service

Expert Support

Custom Tailored Solutions

Advanced Technology

Timely Delivery

Competitive Rate