Electric 2-Wheelers

End-to-End Engineering Solutions for Electric 2-Wheelers

DEP offers a complete suite of engineering, testing, and validation services for electric 2-wheelers, supporting OEMs throughout the full product development cycle. We handle everything from concept and styling support to vehicle architecture, packaging, CAE analysis, structural durability studies, thermal management, and battery–powertrain integration. Our capabilities extend to prototype build support, regulatory compliance testing, EMI/EMC validation, NVH refinement, and performance benchmarking. With deep expertise in EV systems and mobility engineering, DEP ensures that every electric two-wheeler we develop meets the highest standards of safety, reliability, and production readiness.

DEP’s Commitment to Innovation in Electric 2-Wheelers Technology

At Detroit Engineered Products (DEP), we continuously refine our methods to

Our superior engineering solutions and services position us as a key player in the

Industry Applications of DEP EV 2-Wheeler Technology

Key Distinguishers

Transformed Product Development Process

The EV/HEV initiatives are facing lots of design challenges because of increasing dependency on electrical components and overall complexity, coupled with short design cycles. The challenge in working with simulation models & methods is the accuracy of the analysis data and results. This is further complicated by the uncertainty of electric vehicle and battery degradation profile. The objective of DEP’s research program is to extend model-based design with the integration of various component degradation modes and rates.

Advanced Rider Assistance Systems

Blind Spot Detection (BSD): Our BSD technology uses sensors and radars to alert you when vehicles enter your blind spot, enhancing your situational awareness and providing a crucial safety net.

Lane Change Assist (LCA): LCA employs sophisticated algorithms to monitor adjacent lanes, warning you of approaching vehicles and aiding in safer lane changes.

Adaptive Cruise Control (ACC): Our ACC system utilizes intelligent sensors and control mechanisms to regulate your speed and following distance, ensuring a smooth and secure ride.

Rear-end Collision Warning (RCW): The RCW feature in the DEP system monitors traffic behind you. If a vehicle approaches quickly, it activates the hazard lights at a rapid pace to alert other road users, ensuring your safety.

Virtual Validation – CAE

Stiffness, Stability, and Misuse: Ensuring structural integrity under various conditions.

Vibration and Acoustics: Reducing unwanted noise and vibrations for enhanced comfort.

Operational Strength and Fatigue Resistance: Enhancing durability and longevity.

Vehicle Dynamics: Improving handling and maneuverability.

Vehicle Safety: Maximizing safety features and crashworthiness.

Structural Design: Optimizing design for crashworthiness and impact resistance.

Flow Simulations: Analyzing aerodynamics and water management to improve overall efficiency.

DEP’s Electric 2-Wheelers Development Capabilities

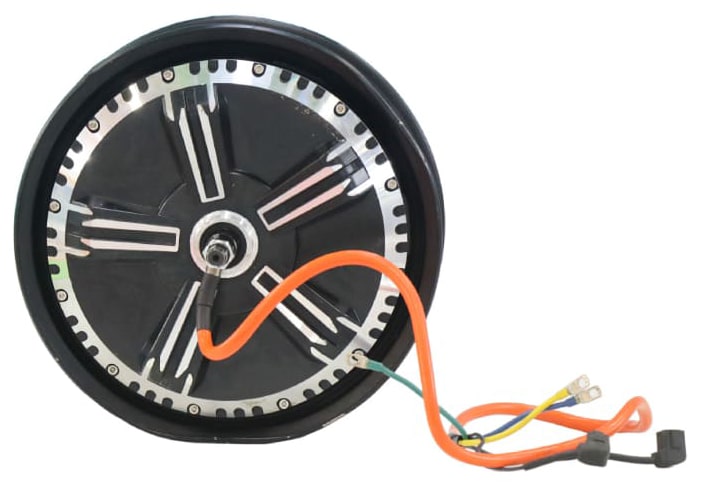

Electric Motor Sizing

Electromagnetic Analysis

Durability analysis

Torque slip analysis

NVH analysis

Durability

Thermal and cooling

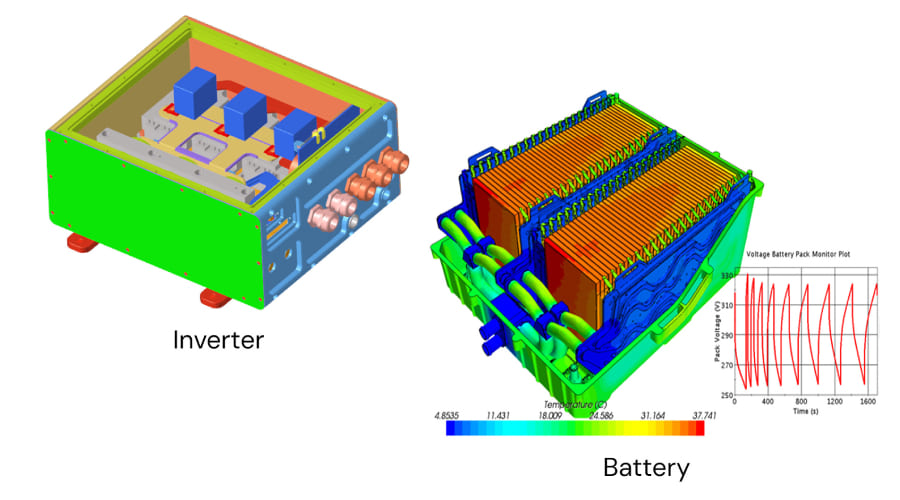

Battery and Inverter

Structural Analysis

Torsional and Bending analysis

Seal analysis

Cell expansion

Side pole – Crash

Pot hole

Bolt sequence analysis

Thermal Analysis

Pressure drop

Full pack thermal analysis

From Prototypes to Production

We create tailored solutions for motorcycles by adapting tried-and-tested automotive series technology. This encompasses:

Advanced Rider Assistance Systems

Anti-Lock Braking Systems (ABS)

Automatic Manual Transmission (AMT) for two-wheeler

Acoustic Vehicle Alerting System (AVAS)

Body Control Unit

DEP Advantages

Building hardware is a great art that requires time and a lot of procedures & guidelines. But evaluating the machine model by connecting them to circuit models is the new extraordinary experience that DEP can provide. With its wide range of simulation solutions for complex EV/HEV powertrain design, DEP makes a significant impact on performance & efficiency of the overall product. Refining the electric motor operation map, battery charge/discharge maps and vehicle dynamics model determining the Complete Modeling process

Customer Benefits

Fully customizable development

Complex EV/HEV powertrain design

Evaluating the machine model