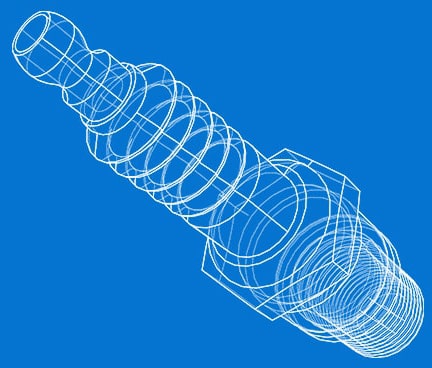

In Cylinder Sensor

Next-Gen In-Cylinder Engine Sensing

DEP offers advanced IC engine sensing technologies that transform the way modern engines are monitored and controlled. Our intelligent in-cylinder combustion sensor, combined with proprietary algorithm-driven processing, delivers multi-function sensing that can significantly reduce reliance on conventional pressure, oxygen, and knock sensors. Through precise real-time feedback to engine control units, DEP enables manufacturers to achieve higher efficiency, lower emissions, and compliance with evolving global standards. This solution equips automakers with a future-ready approach to optimized engine performance and environmental responsibility.

DEP’s Commitment to Innovation in IC & Thermal Runaway Sensor Technology

At Detroit Engineered Products (DEP), we continuously refine our methods to improve

Our superior engineering solutions and services position us as a key player in the

Webinar

Innovative In-Cylinder Sensing Solutions

Key Distinguishers

Thermal Management for the ICE

DEP offers electric pumps, intelligent coolant valves, and sensors for the coolant circuit to support an optimal temperature control of the combustion engine.

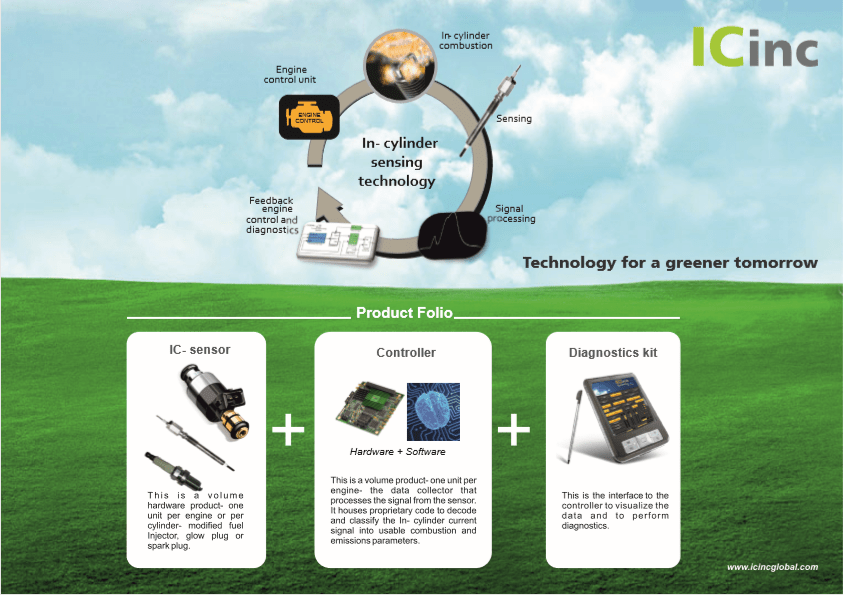

The product is the result of collaboration of DEP and an academic institution who developed the IP and is allowing DEP to help its vision reach the markets. The IC sensor has applications in low volume areas such as racing industries and developmental engines, high volume areas like two and four wheelers, across the global auto sector. The major advantage of this project is providing a disruptive technology that will help build a world with fewer emissions by achieving greater fuel economy.

Thermal Runaway Sensors

Electric vehicles (EVs) are powered by lithium-ion batteries, renowned for their high energy and power density. However, these batteries carry the inherent risk of thermal runaway, a chain reaction of exothermic events within the battery. As a result of this cascade effect, a rapid rise in internal temperature occurs, leading to a destabilization of the internal structure of the battery. Thermal runaway eventually results in battery failure, posing a significant safety risk and compromising the reliability of electric vehicles as a result of battery failure.

Thermal Runaway in an Electric Vehicle

Severe Impact on Safety: Thermal runaway damages the battery pack and vehicle, posing critical risks to occupants.

Common Triggers: Short circuits, overcharging, and cell stresses often cause thermal runaway.

Release of Hazardous Gases: Battery cells emit flammable and toxic gases like hydrogen, carbon monoxide, and hydrogen fluoride.

Difficult to Halt: Once initiated, thermal runaway is hard to stop, often leading to smoke and flames.

Need for Immediate Action: Quick intervention is vital to limit damage and escalation.

Fire Risk Management: Effective strategies are needed to handle gas venting and prevent fires.

DEP’s Sensor Development Capabilities

IC Sensor Capabilities

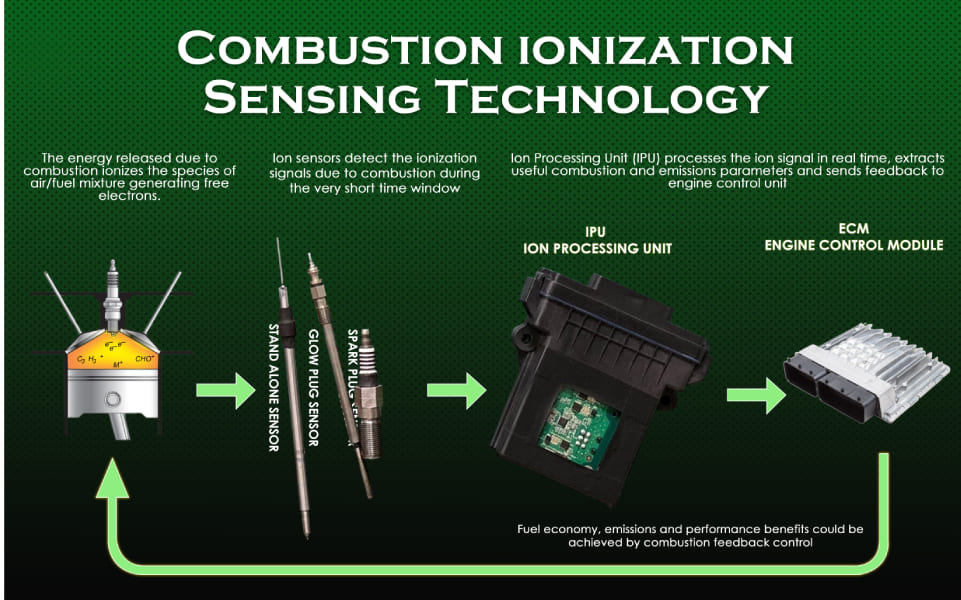

In-cylinder combustion sensors provide real-time engine control feedback for individual cylinder monitoring and advanced combustion regimes.

Cost-effective with low initial and maintenance costs compared to pressure transducers, suitable for volume production.

Retrofittable to existing gasoline and diesel engines without additional modifications, ideal for on-board diagnostics.

Enables remote monitoring and diagnostics for fleets, ensuring optimal engine performance and reducing inspection/repair costs.

DEP Advantages

DEP’s IC sensors offer significant advantages over traditional pressure transducers by predicting combustion, performance, and engine-out emissions at a lower cost. Enhanced by advanced IP algorithms, they deliver precise insights on combustion, performance, and emissions parameters on a cylinder-to-cylinder and cycle-by-cycle basis. These capabilities enable fine-tuning of production engines to meet performance targets over their lifetime without requiring modifications like drilling additional holes in the cylinder head. Similarly, DEP’s Battery Thermal Runaway Sensor provides cost-effective, reliable detection by leveraging fixed parts without optical lenses or catalysts. It accurately identifies charged ions in released gases, operates unaffected by vibrations, and boasts an exceptionally fast response time of under 10 milliseconds. With versatile installation options and no false positives, it ensures dependable and accurate battery monitoring.

Customer Benefits

Cost Efficiency

Operational Principle

Durability

Flexible Instrumentation

Rapid Response Time

Accuracy